Description

| Parameter name | Parameter value |

| Product model | UFC911B110 |

| Manufacturer | ABB |

| Product category | Power interface module, specialized in excitation system power conversion for synchronous generators |

| Input voltage | 110 VDC ±10% (primary power); 24 VDC ±15% (control power) |

| Output current | 10 A continuous; 15 A peak (for 10 seconds) |

| Conversion efficiency | ≥95% at full load |

| Communication protocol | ABB Excitation Bus, Modbus RTU (RS485) |

| Operating temperature | -25°C to +65°C (ambient); -40°C to +75°C (storage) |

| Dimensions (LxWxH) | 250 mm x 180 mm x 100 mm |

| Mounting type | Panel mount with M6 screws (IP20 rated) |

| Protection features | Overcurrent protection, overvoltage clamping, reverse polarity protection |

| Certifications | IEC 60034-1, CE, UL 508, ATEX II 3G Ex nA IIC T4 |

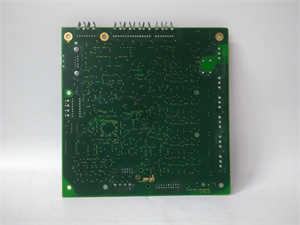

ABB UFC911B110

Product introduction

The UFC911B110 by ABB is a high-efficiency power interface module, engineered to bridge excitation controllers and generator field windings in industrial power systems. As a critical component in ABB’s excitation system portfolio, it converts low-voltage control signals into regulated power outputs, enabling precise control of synchronous generator excitation currents.

This module acts as a power amplifier, translating commands from excitation controllers (such as ABB’s DSSR series) into the high-current signals needed to energize generator field windings. In power plants and industrial cogeneration systems, the UFC911B110 ensures stable field current regulation, directly impacting generator voltage stability and reactive power output. Its robust design allows seamless integration with both new installations and retrofit projects, making it a versatile choice for generator sets ranging from 5 MVA to 50 MVA.

Core advantages and technical highlights

High-efficiency power conversion: With ≥95% efficiency at full load, the UFC911B110 minimizes power loss during conversion. In a 20 MVA diesel generator setup, this efficiency reduces heat dissipation by 30% compared to legacy modules, extending cooling system life and lowering operational costs.

Peak current handling: The module’s 15 A peak output (for 10 seconds) supports transient excitation demands, such as grid fault recovery. A wind farm using UFC911B110 modules reported successful ride-through of voltage dips to 20% rated value, complying with grid codes like FERC Order 827.

Dual power inputs: Separating primary (110 VDC) and control (24 VDC) power enhances reliability. In a combined-cycle plant, a control power failure triggered an automatic switch to backup 24 VDC, preventing generator tripping and avoiding 2 hours of downtime.

Integrated protection: Overcurrent and reverse polarity protection safeguard both the module and connected generator. During a field winding short circuit in a biomass plant, the UFC911B110 shut down within 5 ms, preventing damage to the excitation controller and saving $50,000 in repairs.

Typical application scenarios

In fossil fuel power plants, the UFC911B110 serves as the power stage in generator excitation systems. It receives voltage setpoint signals from a DSSR122 controller, converting them into 10 A field currents to regulate generator terminal voltage. During load changes (e.g., a 10% step increase), the module adjusts output within 20 ms, maintaining voltage stability to within ±0.5% of setpoint—critical for grid compliance.

In industrial cogeneration (e.g., 15 MVA gas turbine generators), the UFC911B110 enables parallel operation with the grid. It modulates field current to control reactive power output (±5 MVAr), optimizing energy costs by reducing reliance on grid-supplied VARs. A chemical plant using this setup cut monthly utility bills by $8,000 through precise reactive power management.

In renewable energy, such as small-scale hydroelectric plants (5–20 MVA), the module adapts to variable water flow. It works with turbine controllers to adjust excitation, ensuring stable power output despite fluctuating turbine speeds. A run-of-river plant reported 99.8% uptime for excitation systems using UFC911B110, up from 97.2% with previous modules.

ABB UFC911B110

Related model recommendations

UFC912B110: A higher-power variant (20 A continuous) of UFC911B110, suited for generators up to 100 MVA. Ideal for large fossil-fuel plants requiring increased current capacity.

DSSR122 4899001-NK: ABB’s excitation controller, directly paired with UFC911B110 to form a complete excitation system. The DSSR122 provides control logic, while UFC911B110 handles power conversion.

UFC760BE41: Analog interface module that connects sensors to UFC911B110, enabling feedback loops for temperature or current monitoring in excitation systems.

CI854A 3BSE030221R1: PROFIBUS DP module that extends UFC911B110’s communication to legacy DCS systems, useful in retrofit projects with mixed protocols.

SDCS-PIN-4: Power input filter, reduces electrical noise entering UFC911B110 from the mains, improving stability in noisy industrial environments.

Installation, commissioning and maintenance instructions

Installation preparation: Mount UFC911B110 on a grounded metal panel using M6 screws (torque 2.5 Nm). Ensure ≥100 mm clearance for airflow. Use 10 AWG cables for power connections and 22 AWG shielded cables for control signals. Verify input voltage matches 110 VDC (primary) and 24 VDC (control); reverse polarity will trigger protection but may damage fuses. Connect protective earth (PE) to the module’s dedicated terminal before powering on.

Commissioning: Power on control power first, then primary power. Use ABB’s Excitation Toolkit software to configure current limits and communication settings. Test output response by sending 0–100% current commands from the controller, verifying linearity (±1% error). Simulate a short circuit on the field output to confirm protection activation within 10 ms.

Maintenance suggestions: Inspect quarterly for loose terminals or corrosion (especially in humid areas). Clean heatsinks with compressed air to remove dust. Annual checks include measuring conversion efficiency (replace if <90%) and testing protection relays. Use ABB’s genuine fuses (15 A slow-blow) for primary power; substitutes may bypass protection. For communication issues, check RS485 termination (120Ω) and update firmware via USB port if errors persist.

Service and guarantee commitment

ABB backs UFC911B110 with a 3-year warranty, covering defects in materials and workmanship. During this period, ABB provides free replacement of faulty modules and 24/7 technical support via its global helpdesk (average response <2 hours for critical issues).

Customers gain access to online resources—including wiring diagrams, calibration guides, and firmware updates—through ABB’s Customer Portal. Optional services include on-site commissioning (with efficiency certification) and operator training (virtual or in-person). ABB guarantees spare parts availability for 12 years post-production, ensuring long-term support for generator fleets. This commitment reflects confidence in UFC911B110’s reliability and dedication to minimizing excitation system downtime.