Description

Detailed parameter table

| Parameter name | Parameter value |

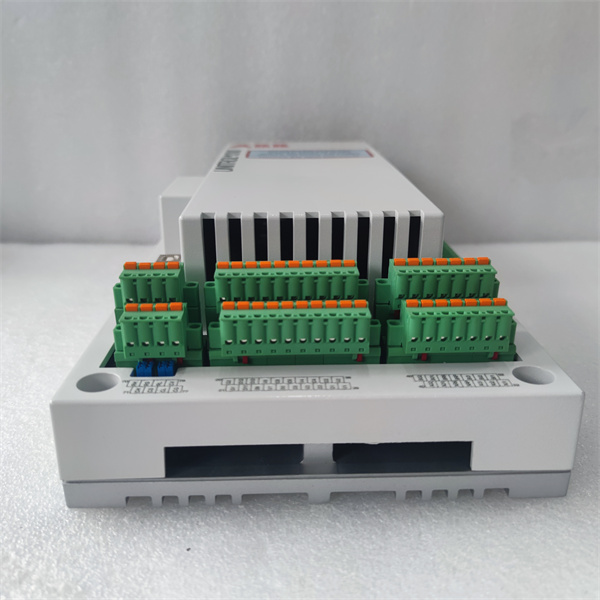

| Product model | UNITROL1010 |

| Manufacturer | ABB |

| Product category | Digital excitation system |

| Rated power range | Suitable for generators with power ranging from [X] MW to [Y] MW |

| Input voltage | 3 – phase, 400 VAC ± 10%, 50/60 Hz |

| Control accuracy | Voltage regulation accuracy within ±0.5% of rated voltage |

| Communication interfaces | Modbus RTU (standard), optional Ethernet for high – speed data transfer and remote monitoring |

| Protection features | Over – voltage protection, under – voltage protection, over – current protection, over – excitation protection, under – excitation protection |

| Operating temperature range | -5°C to +45°C |

| Storage temperature range | -20°C to +70°C |

| Dimensions (LxWxH) | [Length value] mm x [Width value] mm x [Height value] mm (approximate, subject to specific configuration) |

| Weight | Approximately [Weight value] kg |

| Mounting type | Rack – mountable or wall – mountable (with appropriate accessories) |

| Protection class | IP20 (for indoor use); can be enhanced to IP42 with additional enclosures for harsher environments |

ABB UNITROL1010

Product introduction

The ABB UNITROL1010 is a state – of – the – art digital excitation system designed to provide reliable and efficient excitation control for synchronous generators. It serves as a critical component in power generation plants, ensuring stable voltage regulation and optimal generator performance under various operating conditions.

This excitation system is engineered to interface seamlessly with different types of generators, whether they are used in industrial power generation, small – scale power plants, or standby power systems. By precisely controlling the excitation current of the generator’s rotor, the UNITROL1010 can maintain the generator’s output voltage within tight tolerances, even when the load on the generator changes rapidly.

Core advantages and technical highlights

Precise voltage regulation: With a voltage regulation accuracy of within ±0.5% of the rated voltage, the UNITROL1010 ensures that the power generated is of high quality. This is crucial in applications where sensitive electrical equipment is connected to the power grid. For example, in a data center’s standby power system, the stable voltage output provided by the UNITROL1010 – controlled generator prevents voltage fluctuations from damaging servers and other critical IT infrastructure.

Comprehensive protection mechanisms: The system is equipped with a wide range of protection features. Over – voltage protection safeguards the generator from excessive voltage levels that could damage the stator windings. Under – voltage protection ensures that the generator is not operated under conditions that could lead to reduced efficiency or motor stalling. Over – excitation protection and under – excitation protection prevent the generator’s rotor from being over – or under – excited, maintaining the integrity of the magnetic circuit and preventing premature component wear.

Flexible communication options: The standard Modbus RTU interface allows for easy integration with existing control systems, such as PLCs or SCADA systems. This enables operators to monitor and control the excitation system remotely, receive real – time status updates, and adjust parameters as needed. The optional Ethernet interface further enhances the system’s connectivity, providing high – speed data transfer capabilities for more complex monitoring and control applications. For instance, in a large – scale industrial park with multiple power – generating units, the Ethernet – enabled UNITROL1010 can communicate with a central control station, allowing for coordinated control of all generators.

High – reliability design: The UNITROL1010 is built with high – quality components and undergoes rigorous testing to ensure long – term reliability. Its modular design makes it easy to service and maintain, with individual modules that can be quickly replaced in case of a fault. This reduces downtime and maintenance costs, making it an ideal choice for power generation applications where continuous operation is essential.

Typical application scenarios

In industrial power generation, the UNITROL1010 is commonly used in manufacturing plants with their own power – generation facilities. For example, in a steel mill, the excitation system controls the generators that power the electric arc furnaces, rolling mills, and other high – power equipment. By maintaining stable voltage levels, it ensures smooth operation of these energy – intensive processes, reducing the risk of production disruptions due to power quality issues.

Small – scale power plants, such as those using diesel generators or hydro – power generators, also benefit from the UNITROL1010. In a rural area powered by a small hydro – power plant, the excitation system regulates the generator’s output voltage to match the load requirements of the local community. This helps in providing reliable electricity supply to homes and small businesses, even during peak demand periods.

Standby power systems, like those in hospitals, banks, and telecommunication facilities, rely on the UNITROL1010 to ensure a seamless transition to backup power in case of a mains power failure. In a hospital, for instance, the generator controlled by the UNITROL1010 powers life – support systems, operating room equipment, and lighting. The precise voltage regulation and quick response time of the excitation system are critical for maintaining the safety and functionality of these essential services.

ABB UNITROL1010

Related model recommendations

UNITROL5000: A more advanced and high – capacity digital excitation system from ABB, suitable for large – scale power plants with generators in the multi – megawatt range. It offers additional features such as enhanced fault diagnosis capabilities and advanced control algorithms for optimizing generator performance under extreme load conditions.

AC800M: ABB’s modular PLC, which can be integrated with the UNITROL1010 to provide a comprehensive control solution. The PLC can process data from various sensors in the power generation system, including the excitation system, and execute control logic to optimize overall system performance.

CI854A: A Profibus DP communication module that can be used in combination with the UNITROL1010 (when paired with a Modbus – to – Profibus gateway) to expand its network capabilities in industrial automation networks where Profibus is the dominant communication protocol.

TB521: A terminal block accessory with surge protection, useful when installing the UNITROL1010 in environments where electrical surges are common, such as near power distribution panels or in areas with frequent lightning strikes. This helps protect the excitation system from voltage spikes that could damage its sensitive electronics.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the UNITROL1010, ensure that the mounting location is clean, dry, and free from vibrations. If wall – mounting, use appropriate wall – mounting brackets and ensure that the wall can support the weight of the system. For rack – mounting, verify that the rack is properly grounded and has sufficient space for the UNITROL1010 and any associated components. Use ESD – safe tools and wear anti – static wristbands to avoid damaging the sensitive electronics during installation.

Maintenance suggestions: Regularly inspect the UNITROL1010 for any signs of physical damage, such as loose connections or damaged components. Check the temperature of the system during operation; if it exceeds the normal operating range, investigate for potential cooling issues, such as blocked ventilation openings. Periodically clean the system with compressed air (at a pressure not exceeding 5 bar) to remove dust and debris, which can affect heat dissipation. If communication errors occur, check the communication cables for breaks or loose connections. Verify the communication settings on the UNITROL1010 and the connected devices to ensure they match. In case of any faults, refer to the ABB diagnostic manuals for troubleshooting steps.

Commissioning process: After installation, power up the system and check for any error messages on the display panel. Use ABB’s dedicated commissioning software to configure the system’s parameters, such as generator ratings, voltage regulation settings, and communication settings. Conduct a series of tests, including no – load tests, load – step tests, and fault – simulation tests, to ensure that the UNITROL1010 is operating correctly. Monitor the generator’s voltage, current, and other parameters during these tests and make any necessary adjustments to the system’s parameters.

Service and guarantee commitment

ABB offers a 3 – year warranty for the UNITROL1010, covering defects in materials and workmanship. During this period, if the system fails due to manufacturing defects, ABB will provide a free replacement or repair. Customers can access ABB’s global technical support network, which is available 24/7 for troubleshooting and technical advice. ABB also provides a comprehensive library of technical documentation, including user manuals, installation guides, and application notes, to assist customers in using and maintaining the system. In addition, optional on – site commissioning and maintenance services are available for customers who require hands – on support. ABB ensures the availability of spare parts for at least 10 years after the product’s production phase, minimizing the risk of system downtime due to unavailability of replacement parts.