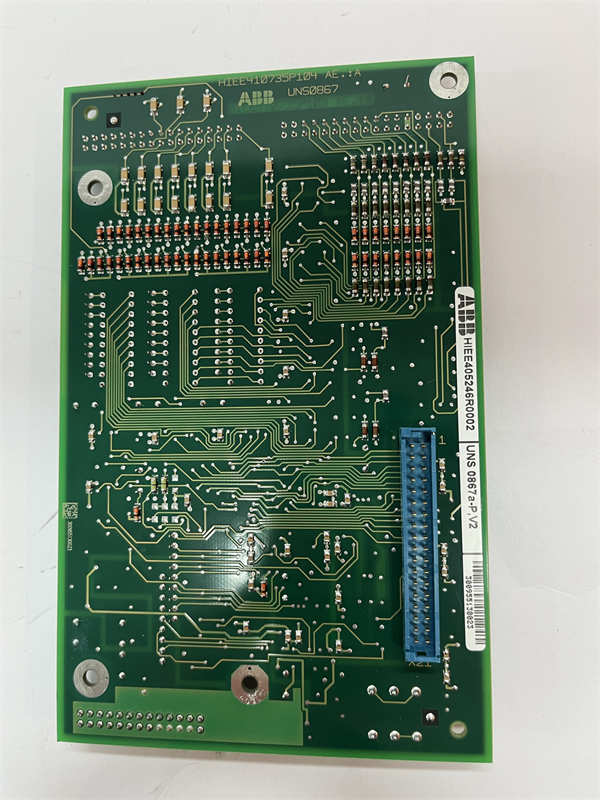

Description

| Parameter name | Parameter value |

| Product model | UNS0867A-P,V2 HIEE405246R0002 |

| Manufacturer | ABB |

| Product category | Safety PLC module, part of ABB’s AC 800M safety controller family |

| Safety integrity level | SIL 3 (per IEC 61508), PL e (per ISO 13849-1) |

| Input/output channels | 8 safety-related digital inputs (24 VDC, PNP/NPN configurable); 4 safety-related digital outputs (24 VDC, 2 A max per channel) |

| Communication interface | Profibus DP (safety-certified), Ethernet (for configuration) |

| Power supply | 24 VDC ±15%, 18 W max |

| Operating temperature | -25°C to +60°C (ambient); -40°C to +70°C (storage) |

| Dimensions (LxWxH) | 190 mm x 100 mm x 60 mm |

| Mounting type | DIN rail (35mm) with locking clips |

| Protection class | IP20 with conformal coating (IEC 60068-2-6) |

| Certifications | TÜV SÜD, ATEX, IECEx, UL 1998 |

UNS0867A-P,V2 HIEE405246R0002

Product introduction

The UNS0867A-P,V2 HIEE405246R0002 is a high-integrity safety PLC module from ABB, engineered to monitor and control safety-critical processes in industrial environments. As a key component of ABB’s AC 800M safety controller system, it combines advanced safety logic with robust hardware to prevent hazardous events in machinery and industrial plants.

This module processes safety-related signals from emergency stops, light curtains, and interlock switches, executing pre-programmed safety functions to halt processes or activate protective measures when risks are detected. The UNS0867A-P,V2 HIEE405246R0002 operates independently of standard control systems, ensuring safety functions remain active even if non-safety components fail. In industries where human-machine interaction is frequent—such as automotive manufacturing or chemical processing—this module acts as a reliable safeguard, reducing accident risks while maintaining operational efficiency.

Core advantages and technical highlights

Dual-core architecture for safety redundancy: The UNS0867A-P,V2 HIEE405246R0002 features two independent processing cores that continuously cross-verify results. This redundancy eliminates single points of failure, a critical requirement for SIL 3 applications. In a pharmaceutical packaging line, this design prevented a costly shutdown by detecting a core mismatch during routine operation, allowing maintenance to address the issue before a safety function was compromised.

Flexible input/output configuration: With 8 configurable inputs and 4 outputs, the module adapts to diverse safety devices without hardware modifications. Inputs can switch between PNP and NPN logic via software, while outputs support both direct load control and relay driving. A food and beverage plant used this flexibility to integrate legacy emergency stops with new light curtains, avoiding $20,000 in sensor replacement costs.

Seamless safety communication: The Profibus DP safety interface enables secure data exchange with other safety components, such as ABB’s UNS0866A modules, without compromising integrity. In an automotive weld shop, 12 UNS0867A-P,V2 HIEE405246R0002 modules communicated via Profibus to coordinate safety zones, reducing response time to emergency stops by 40% compared to hardwired systems.

Diagnostic capabilities for proactive maintenance: Built-in diagnostics monitor channel health, communication status, and power supply stability, with alerts sent to the HMI via Ethernet. A chemical plant used these diagnostics to identify a deteriorating light curtain sensor before it failed, replacing it during scheduled downtime and avoiding unplanned production stops.

Typical application scenarios

In automotive assembly lines, the UNS0867A-P,V2 HIEE405246R0002 controls access to robotic workcells. It monitors safety interlocks on cell doors and light curtains around robot perimeters; if a worker enters the hazardous area, the module triggers an immediate stop of robotic motion within 10ms. This response meets ISO 10218-1 requirements, protecting workers while allowing quick restart of production once the area is clear.

In chemical processing plants, the module oversees batch reactor safety systems. It monitors pressure relief valves, temperature limits, and gas detection sensors. If a toxic gas leak is detected, the UNS0867A-P,V2 HIEE405246R0002 closes isolation valves, shuts down feed pumps, and activates ventilation—all within 50ms—to contain the hazard. Its SIL 3 rating ensures these actions are reliable even during electrical noise or transient faults common in chemical facilities.

In material handling systems, such as automated storage and retrieval (AS/RS) units, the module safeguards against collisions. It processes signals from position encoders and safety laser scanners, stopping crane movement if obstacles are detected. A logistics center using 8 UNS0867A-P,V2 HIEE405246R0002 modules reduced equipment damage incidents by 90% by preventing crane-to-rack collisions.

UNS0867A-P,V2 HIEE405246R0002

Related model recommendations

UNS0866A HIEE405245R0001: A complementary safety module with 16 digital inputs, ideal for systems requiring more sensor connections—e.g., large-scale packaging lines with multiple safety zones.

PM864K01: ABB’s standard PLC module, pairs with UNS0867A-P,V2 HIEE405246R0002 to combine safety and standard control in a single rack, simplifying integration in hybrid systems.

CI854A 3BSE030221R1: Profibus DP communication module, extends the module’s reach to non-safety Profibus devices while maintaining safety network integrity.

DI810 3BSE008549R1: Standard digital input module, used alongside UNS0867A-P,V2 HIEE405246R0002 for non-safety signals, keeping safety and standard I/O separate for compliance.

DO820 3BSE008551R1: Standard digital output module, controls non-critical actuators while the safety module handles emergency functions—e.g., in a conveyor system where normal stops use DO820 and emergency stops use UNS0867A-P,V2 HIEE405246R0002.

Installation, commissioning and maintenance instructions

Installation preparation: Mount UNS0867A-P,V2 HIEE405246R0002 on a grounded 35mm DIN rail in a NEMA 4 enclosure, ensuring 50mm clearance for airflow. Use shielded twisted-pair cables (0.5mm²) for safety inputs/outputs, with shields grounded at both ends to prevent EMI. Verify 24 VDC power supply ripple <100mV; use a dedicated safety power supply (per IEC 61131-2) to avoid cross-contamination with non-safety circuits. Label all connections clearly to distinguish safety from standard wiring.

Commissioning: Power on the module and use ABB’s Safety Builder software to configure safety logic (e.g., emergency stop interlocks, two-hand control). Validate SIL 3 compliance via built-in self-tests, checking input response times (<10ms) and output contact integrity. Test safety functions under fault conditions—e.g., disconnect a sensor wire to confirm the module triggers a safe state within 20ms. Document all test results for regulatory compliance.

Maintenance suggestions: Inspect monthly for loose terminals or corrosion, especially in humid environments. Clean conformal coating with a dry cloth to remove dust. Annually verify safety functionality via forced fault tests (per ISO 13849-1) and check input/output calibration using a precision multimeter. Replace output relays after 100,000 cycles (use ABB part 3HAC031684-001) to prevent contact degradation. For communication issues, check Profibus termination (120Ω) and update firmware via Safety Builder if errors persist.

Service and guarantee commitment

ABB backs UNS0867A-P,V2 HIEE405246R0002 with a 5-year warranty, covering defects in materials and workmanship. During this period, ABB provides free replacement of faulty modules and 24/7 technical support via its global safety specialists, with average response times <4 hours for critical issues.

Customers gain access to safety certification documents, wiring diagrams, and software updates via ABB’s Customer Portal. Optional services include on-site safety validation (with TÜV 见证) and functional safety training for engineers. ABB guarantees spare parts availability for 10 years post-production, ensuring long-term support for safety-critical systems. This commitment reflects confidence in the module’s reliability and dedication to helping customers maintain compliance with global safety standards.