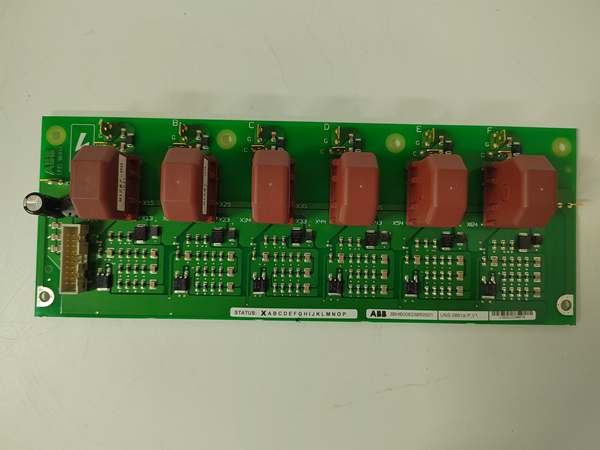

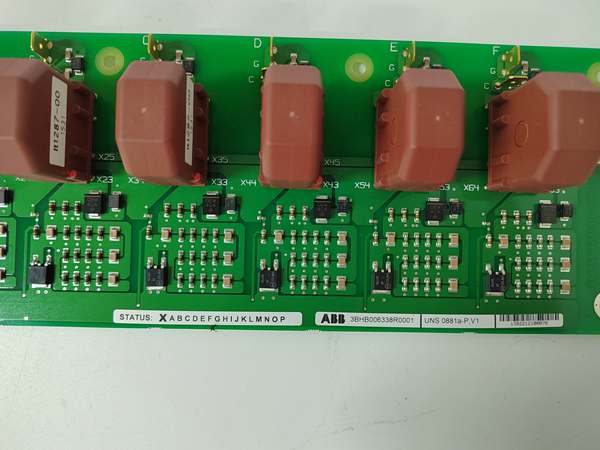

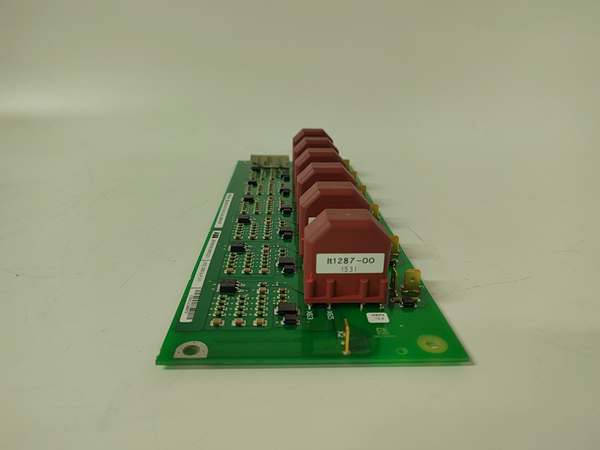

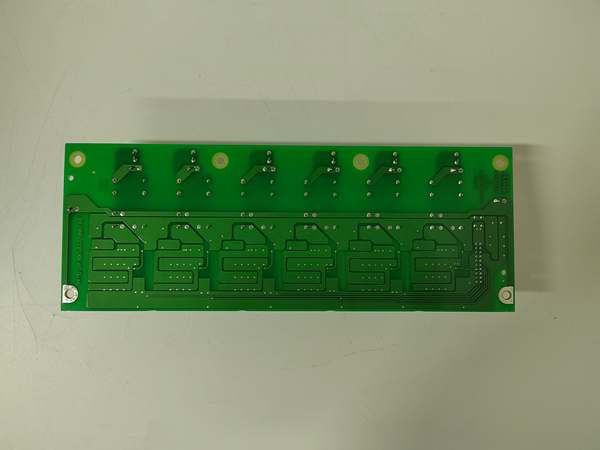

Description

ABB UNS0881a-P V1

-

Model Number: UNS0881a-P V1 -

Manufacturer: ABB -

Product Type: Redundant Process Control Processor -

Processor: PowerPC 750, 800 MHz -

Memory: 256MB RAM, 1GB Flash (user/application storage) -

Redundancy Support: Active/standby (hot standby), automatic failover ≤100ms -

Communication Protocols: Ethernet/IP, Profibus DP, Modbus TCP, IEC 61850 (optional) -

Operating Temperature: -25°C to +60°C -

Humidity Range: 5% to 95% non-condensing -

Power Supply: 24V DC (18-32V DC range, redundant inputs supported) -

Power Consumption: 12W (typical, single processor) -

I/O Capacity: Up to 32,000 I/O points (via Symphony Harmony I/O modules) -

Dimensions: 245mm x 135mm x 115mm (width x height x depth, fits Symphony rack) -

Weight: 1.0kg -

Certifications: CE, UL, cULus, ATEX (Zone 2), RoHS

ABB UNS0881a-P V1