Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | V18345-1010221001 |

| Manufacturer | ABB |

| Product Category | Pneumatic positioner (for control valves, part of the TZIDC series) |

| Actuation Type | Pneumatic (double-acting) |

| Input Signal | 4-20 mA DC |

| Output Pressure Range | 0.2-1.0 bar (3-15 psi) for double-acting actuators |

| Supply Pressure | 1.4-1.6 bar (20-23 psi) |

| Positioning Accuracy | ±0.5% of full scale |

| Response Time | ≤ 0.5 seconds (for 90% step change) |

| Temperature Range | -20°C to +80°C |

| Protection Class | IP66 (weatherproof) |

| Mounting Standard | VDI/VDE 3845, NAMUR (ISO 5211) |

| Communication Options | Optional HART protocol (for configuration and diagnostics) |

| Material | Housing: Aluminum (painted); Internals: Stainless steel, brass |

| Weight | Approx. 2.5 kg |

| Compliance | IEC 61508 (SIL 2 capable), ATEX, IECEx, CE |

| Compatible Valves | ABB V-ball valves, butterfly valves, globe valves, V18345-1010222001 (single-acting variant) |

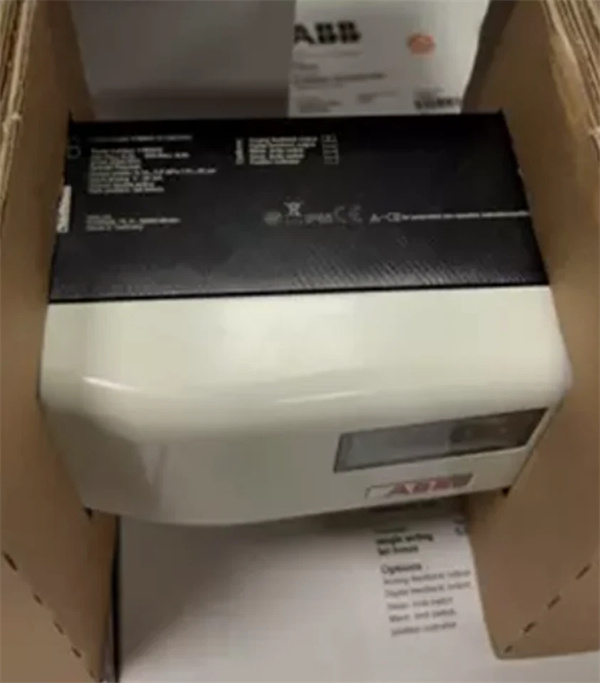

ABB V18345-1010221001

Product Introduction

The V18345-1010221001 is a high-performance pneumatic positioner from ABB, part of the TZIDC series, designed to precisely control the position of double-acting valve actuators in industrial process systems. As a critical component in flow control, it converts a 4-20 mA electrical input signal into proportional pneumatic pressure, adjusting valve stem position to regulate fluid flow, pressure, or level in pipelines.

Engineered for accuracy and reliability, this positioner ensures valves respond precisely to control signals, even in harsh environments. Its robust aluminum housing and IP66 protection make it suitable for outdoor installations and industrial areas with dust, moisture, or vibration. With optional HART communication, it enables remote configuration, calibration, and diagnostics, integrating seamlessly with distributed control systems (DCS) in industries such as oil and gas, chemical processing, and water treatment. Whether paired with ABB V-ball valves or third-party actuators, the V18345-1010221001 delivers consistent performance, optimizing process efficiency and reducing maintenance costs.

Core Advantages and Technical Highlights

High positioning accuracy

With ±0.5% accuracy and fast response time (≤0.5 seconds), the V18345-1010221001 ensures precise valve control in critical processes. In a refinery’s distillation column, this accuracy maintains flow rates within ±0.5% of setpoints, preventing product quality variations and ensuring compliance with safety regulations. Even with supply pressure fluctuations, the positioner compensates to keep valve position stable.

Robust environmental resistance

The IP66-rated aluminum housing and wide temperature range (-20°C to +80°C) make the positioner suitable for extreme conditions. In a desert oil pipeline station, it withstands sandstorms and 50°C daytime temperatures without performance degradation, while in a northern water treatment plant, it operates reliably during -20°C winters—eliminating the need for heated enclosures.

HART-enabled diagnostics

Optional HART protocol support allows remote monitoring of valve position, air supply pressure, and internal faults. In a chemical plant’s batch process, maintenance teams use HART to detect a gradual increase in valve friction (indicated by higher air consumption), scheduling preventive maintenance before a costly unplanned shutdown. This predictive capability reduces downtime by up to 30% compared to manual inspections.

Typical Application Scenarios

In an offshore oil platform’s production manifold:

V18345-1010221001 positioners control double-acting actuators on 6-inch V-ball valves, regulating crude oil flow to separators.

4-20 mA signals from the platform’s DCS adjust valve position, with the positioner maintaining accuracy despite vibration from nearby pumps.

ATEX certification ensures safe operation in hazardous areas (Zone 1), while HART diagnostics alert operators to low supply pressure before valve response is affected.

In a municipal wastewater treatment plant’s aeration system:

The positioner controls butterfly valves regulating air flow to aeration basins, where precise oxygen levels are critical for biological treatment.

Its IP66 rating withstands occasional water spray during basin cleaning, and stainless steel internals resist corrosion from humid, chemically treated air.

Integration with the plant’s SCADA system via HART allows remote adjustment of airflow setpoints, optimizing energy use by matching oxygen supply to biological demand.

ABB V18345-1010221001

Related Model Recommendations

V18345-1010222001: Single-acting variant of V18345-1010221001 for spring-return actuators.

V28000 series: ABB V-ball valves optimized for use with V18345-1010221001 positioners.

TZIDC-HART adapter: Adds HART communication to non-communicating versions of V18345-1010221001.

352A I/P transducer: Converts 4-20 mA signals to pneumatic pressure, compatible with legacy systems.

V18345-1010223001: Explosion-proof version (ATEX Zone 0) for highly hazardous environments.

ValveLink software: Used to configure, calibrate, and diagnose V18345-1010221001 via HART.

Installation, Commissioning and Maintenance Instructions

Installation preparation

Mount V18345-1010221001 directly to the valve actuator using NAMUR (ISO 5211) mounting holes, ensuring alignment with the actuator’s feedback shaft. Connect the 4-20 mA input signal (shielded cable) to terminals 1 (+) and 2 (-), and the pneumatic supply (1.4-1.6 bar) to the “Supply” port. Connect output pressure lines to the actuator’s “Open” and “Close” ports. For HART communication, connect a HART modem to the signal wires. Ensure the housing is oriented to prevent water ingress (cable entries downward).

Calibration procedure

Using ABB ValveLink software or a HART communicator:

Perform a “zero” calibration: Apply 4 mA signal and adjust until the valve reaches the fully closed position.

Perform a “span” calibration: Apply 20 mA signal and adjust until the valve reaches full open.

Verify mid-stroke position (12 mA) for accuracy, adjusting if necessary.

Test step responses (e.g., 4-12-20 mA) to confirm smooth, overshoot-free movement.

Maintenance suggestions

Inspect V18345-1010221001 quarterly: check for air leaks at connections, ensure the feedback linkage is tight, and clean the housing with a damp cloth. Test position accuracy annually using a calibrator—drifts exceeding ±1% indicate the need for recalibration. Replace the air filter/regulator every 2 years to prevent contamination of internal components. If HART diagnostics report excessive friction or worn seals, replace the positioner’s internal diaphragm kit (available as a spare part) to restore performance.

Service and Guarantee Commitment

The V18345-1010221001 is backed by a 5-year warranty, covering defects in materials and workmanship under normal operating conditions. ABB’s valve service team provides on-site installation support, including alignment checks and HART configuration.

Customers receive access to detailed calibration guides and HART protocol documentation for V18345-1010221001. ABB offers training programs on positioner maintenance and troubleshooting, ensuring users can maximize performance. With global service centers, replacement parts and units are available for rapid delivery, minimizing valve downtime in critical processes.