Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | VA-MC15-05 |

| Brand | ABB |

| Application scope | Manufacturing, automotive, energy and other industries |

| Operating voltage | 220 V |

| Output frequency | 30 kHz |

| Certification | CE, RoHS |

| Weight | 0.5 kg |

| Dimensions | 15 cm × 10 cm × 5 cm |

| Output current | 3000 mA (related to specific driving capacity, e.g., can drive 100W devices) |

| Output voltage range | 22 – 42 V (for driving specific loads) |

| Communication interface | RS485 |

| Special features | Built – in probe (e.g., for certain monitoring functions like single CO₂ detection up to 5000ppm), suitable for measuring three – phase voltages in related applications |

| Input voltage for some functions | 24 V (for specific signal output conversion, e.g., output 4 – 20mA, 0 – 5V) |

| Wire characteristics | Waterproof wire, length 0 – 5 meters |

| Probe protection level | IP68 |

Product introduction

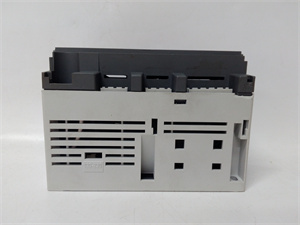

The ABB VA – MC15 – 05 is a high – performance industrial controller module meticulously engineered to meet the exacting requirements of modern industrial automation and control scenarios. It serves as a critical component in a wide array of industries, such as manufacturing, automotive, and energy sectors, where precision and reliability are non – negotiable.

This module is designed to integrate seamlessly into existing industrial systems, offering a stable and efficient control solution. With its compact dimensions of 15 cm × 10 cm × 5 cm and a lightweight design weighing only 0.5 kg, it can be easily installed in various control cabinets or equipment, saving valuable space. The VA – MC15 – 05 operates at a voltage of 220 V, with an output frequency of 30 kHz, ensuring high – speed and accurate control responses.

Equipped with an RS485 communication interface, it enables convenient data exchange and interaction with other devices in the industrial network. The built – in probe, which can detect substances like single CO₂ up to 5000ppm, adds an extra layer of monitoring functionality, making it suitable for applications where environmental or process parameter monitoring is crucial. Additionally, its ability to handle input and output voltage conversions, such as converting 24 V input to 4 – 20mA or 0 – 5V outputs, further expands its versatility in different industrial setups.

ABB 07KR51 220VDC

Core advantages and technical highlights

High – voltage operation

Operating at 220 V, the VA – MC15 – 05 can power and control a wide range of industrial equipment directly. This high operating voltage not only reduces the need for additional voltage – boosting or conversion equipment in some cases but also allows for more efficient power transfer over longer distances. For example, in a large – scale manufacturing plant, it can directly supply power to motors or actuators, eliminating the complexity and potential energy losses associated with multiple voltage – conversion steps.

High – frequency output

With an output frequency of 30 kHz, the module can provide rapid and precise control signals. This high – frequency output is especially beneficial for applications that require quick – response control, such as high – speed robotic arms in automotive manufacturing. The fast – switching nature of the 30 kHz output enables the robotic arms to move more smoothly and accurately, reducing cycle times and increasing overall production efficiency.

Customizability

The VA – MC15 – 05 is highly customizable to suit specific industrial applications. Its software and hardware can be configured to adapt to different control algorithms, communication protocols, and sensor inputs. For instance, in an energy – intensive industrial process, it can be customized to integrate with various energy – monitoring sensors and control equipment to optimize energy consumption. The ability to fine – tune the module according to specific needs ensures that it can be tailored to the unique requirements of each industrial environment.

Certification – compliant

Carrying CE and RoHS certifications, the VA – MC15 – 05 complies with strict European safety, health, and environmental protection standards. The CE mark indicates that the product meets the essential requirements of relevant European health, safety, and environmental protection directives, ensuring its safe use in industrial settings across Europe. The RoHS certification, on the other hand, ensures that the module is free from hazardous substances such as lead, mercury, and cadmium, making it environmentally friendly and suitable for use in industries that are increasingly focused on sustainable practices.

Robust design

Built with premium materials, the VA – MC15 – 05 is designed to withstand harsh industrial conditions. Its rugged construction can resist vibrations, shocks, and electromagnetic interference commonly found in industrial environments. For example, in a manufacturing plant with heavy machinery operating nearby, the module’s robust design ensures that it continues to function accurately without being affected by the vibrations and electromagnetic fields generated by the machinery. This durability reduces the risk of equipment failures and maintenance requirements, leading to lower operational costs over time.

Precise monitoring capabilities

The built – in probe with a specific monitoring function, such as single CO₂ detection up to 5000ppm, allows for real – time monitoring of critical parameters in industrial processes. In industries like chemical manufacturing or food processing, where maintaining a certain environmental condition is crucial, the VA – MC15 – 05 can provide accurate data on the presence of CO₂. This data can then be used to adjust ventilation systems, control chemical reactions, or ensure product quality. The probe’s high – precision measurements contribute to better process control and overall system efficiency.

Typical application scenarios

Manufacturing industry

In a manufacturing plant that produces electronic components, the ABB VA – MC15 – 05 can be used to control the movement of automated assembly lines. Its high – speed output frequency of 30 kHz enables the precise control of conveyor belts and robotic arms, ensuring that components are assembled accurately and at a high speed. The module’s ability to interface with various sensors via the RS485 communication interface allows it to detect any faults or misalignments in the assembly process in real – time. For example, if a sensor detects a missing component, the VA – MC15 – 05 can immediately stop the assembly line and trigger an alarm, preventing defective products from being produced.

Automotive industry

In an automotive production facility, the VA – MC15 – 05 can be utilized in the painting process. It can control the speed and pressure of paint – spraying robots, ensuring an even and high – quality paint finish on car bodies. The module’s customizability allows it to be programmed to adjust the paint – spraying parameters based on the shape and size of different car models. Additionally, the built – in probe can be used to monitor the air quality in the painting booth, detecting any harmful substances such as volatile organic compounds (VOCs) or CO₂. If the concentration of these substances exceeds the set limits, the VA – MC15 – 05 can trigger ventilation systems to improve air quality, protecting the health of workers and ensuring compliance with environmental regulations.

Energy sector

In a wind – power generation station, the VA – MC15 – 05 can play a role in the control system of small wind turbines. It can monitor the three – phase voltages of the turbine’s power output, similar to the functions of ABB’s VI15x voltage modules. By detecting under – voltage, over – voltage, or power – factor issues, the module can protect the turbine’s inverters and other electrical components. The module’s ability to handle different input and output voltage conversions can be used to interface with various sensors and control devices in the wind – turbine system. For example, it can convert the 24 V output of a wind – speed sensor to a 4 – 20mA signal that can be easily processed by the main control system of the wind – power station.

Related model recommendations

ABB VA – MC15 – 10

This is a more powerful variant of the VA – MC15 – 05, with a higher output current capacity. It is suitable for applications that require more power to drive larger motors or actuators. For example, in a heavy – duty manufacturing process where larger machinery is involved, the VA – MC15 – 10 can provide the necessary power and control precision.

ABB AC800PEC PM864

When paired with the VA – MC15 – 05, the AC800PEC PM864 high – performance controller can offer advanced power management and diagnostic capabilities. This combination is beneficial for complex industrial automation systems, where comprehensive control and monitoring are required. The PM864 can receive data from the VA – MC15 – 05, analyze it, and make real – time decisions to optimize the operation of the entire system.

ABB TB857 3BSE013269R1

This surge – protected terminal block, with enhanced EMI filtering, can be used in conjunction with the VA – MC15 – 05. It helps to protect the module from voltage surges and electromagnetic interference, ensuring its stable operation in harsh electrical environments. In industrial settings where there are frequent electrical transients, such as near large – scale power – distribution equipment, the TB857 can safeguard the VA – MC15 – 05 from potential damage.

ABB CI854A 3BSE022469R1

The CI854A PROFINET interface module, when powered by the VA – MC15 – 05, enables high – speed data exchange in industrial networks. This is useful for applications that require rapid communication between different devices in a factory – wide automation system. For example, in a smart manufacturing plant, the CI854A can transfer data from the VA – MC15 – 05 to other controllers or monitoring systems in real – time, facilitating seamless integration and coordination of various production processes.

Installation, commissioning and maintenance instructions

Installation preparation

Select an appropriate installation location in the control cabinet or equipment. Ensure that the location is well – ventilated to prevent overheating, as the module may generate some heat during operation.

Verify that the operating voltage of 220 V in the installation environment matches the module’s requirements. Install a dedicated circuit breaker with an appropriate rating (e.g., 5 A) to protect the module from overcurrent.

Prepare the necessary installation tools, including a screwdriver, wire strippers, and a multimeter for voltage and resistance measurements.

When connecting wires, use appropriate – gauge insulated wires. For the 220 V input, use 1.5 mm² wires, and for the output connections, use 1.0 mm² wires. Color – code the wires to distinguish between different functions, such as power inputs, signal outputs, and sensor connections.

Commissioning steps

After installation, carefully double – check all wire connections to ensure they are secure and correctly wired.

Power on the module. Observe the status LEDs on the module. A green “Power” LED should illuminate, indicating that the module has received power successfully.

Use a suitable programming or configuration tool (such as ABB – specific software) to configure the module according to the requirements of the application. Set parameters such as output voltage levels (22 – 42 V as needed), communication protocols (RS485 settings), and any custom control algorithms.

Test the module’s basic functions. For example, if it is connected to a motor, check if the motor starts and stops smoothly when commanded by the module. Measure the output voltage and current using a multimeter to ensure they are within the specified ranges.

Test the communication interface. Send and receive data through the RS485 interface to verify that the module can communicate effectively with other devices in the network.

If the module has a built – in probe (e.g., for CO₂ detection), test its functionality by exposing it to known concentrations of the target substance and checking if the module provides accurate readings.

Maintenance suggestions

Regularly inspect the module for any signs of physical damage, such as cracks in the casing or loose wire connections. Check for dust accumulation, especially in the ventilation openings, and clean the module using a soft, dry brush or compressed air (at a low pressure to avoid electrostatic discharge) at least once a month.

Periodically measure the operating voltage and current of the module using a multimeter. Compare the measured values with the specified parameters. If there are significant deviations (e.g., more than ±5% for voltage), investigate the cause, which could be a problem with the power supply or an internal fault in the module.

Check the communication interface periodically to ensure that data transfer is stable. If there are communication errors, check the cable connections, the communication settings in the module and other connected devices, and the integrity of the communication protocol.

For the built – in probe, if applicable, perform calibration checks at least once a year. Use standard calibration gases or reference materials to ensure the accuracy of the probe’s measurements. If the probe shows signs of drift or inaccurate readings, recalibrate it according to the manufacturer’s instructions.

Keep a record of the module’s operating history, including any faults or maintenance activities. This record can be useful for predicting potential failures and scheduling preventive maintenance.

Service and guarantee commitment

ABB offers a comprehensive service and guarantee for the VA – MC15 – 05. The module comes with a 36 – month warranty from the date of purchase, covering manufacturing defects and ensuring that the product meets the specified performance standards. In case of a faulty module, ABB guarantees a replacement within 72 hours for non – critical applications and 24 hours for critical applications, with priority shipping to minimize downtime.

Technical support is available 24/7 from ABB’s global team of industrial control experts. They can provide assistance with installation, configuration, fault diagnosis, and custom – application development. Online resources include detailed user manuals, wiring diagrams, and software – configuration guides. Customers can also opt for extended service contracts, which offer annual preventive maintenance, calibration services, and on – site support during system upgrades, ensuring the long – term reliable operation of the VA – MC15 – 05 throughout its expected 10 – year design lifespan.