Description

Detailed parameter table

| Parameter name | Parameter value |

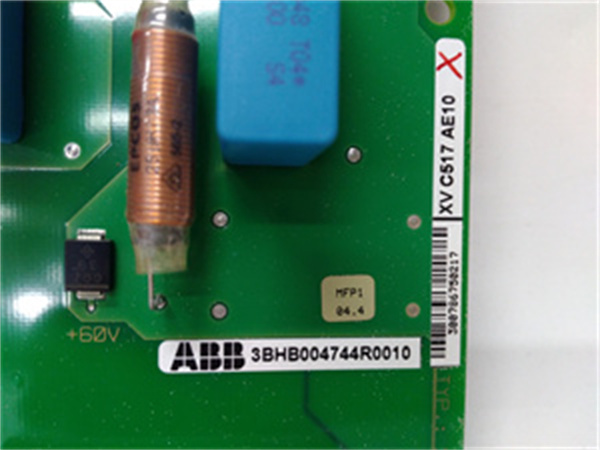

| Product model | XVC517AE10 3BHB004744R0010 |

| Manufacturer | ABB |

| Product category | Industrial operator panel (HMI) |

| Display size | 10.1-inch color TFT |

| Resolution | 1024 × 600 pixels |

| Touch technology | Resistive touchscreen (multi-touch compatible) |

| Processor | ARM Cortex-A9, 1 GHz |

| Memory | 1 GB RAM, 8 GB flash storage |

| Communication ports | 2 × Ethernet (10/100 Mbps), 2 × USB 2.0, 1 × RS485 |

| Supported protocols | Modbus TCP, PROFIBUS DP, EtherNet/IP, OPC UA |

| Operating system | Windows Embedded Standard 7 |

| Operating voltage | 24 V DC ±15% |

| Power consumption | Max 15 W |

| Operating temperature | -10°C to 50°C |

| Dimensions | 270mm × 190mm × 50mm |

| Mounting type | Panel mount (IP65 front) |

| Protection rating | IP65 (front), IP20 (rear) |

| Certifications | CE, UL, IEC 61131-2, ATEX |

ABB XVC517AE10 3BHB004744R0010

Product introduction

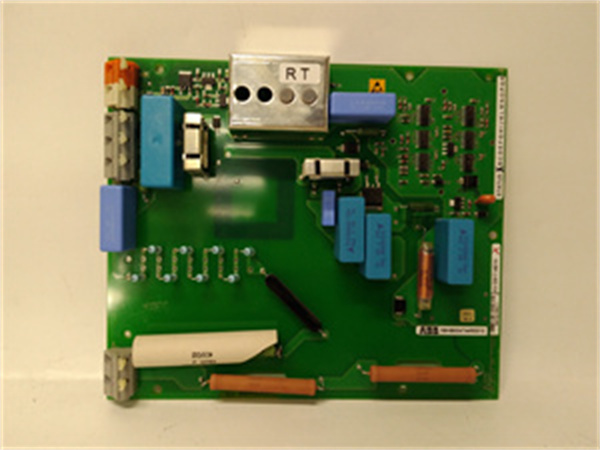

The ABB XVC517AE10 3BHB004744R0010 is a rugged industrial operator panel (HMI) designed to serve as the primary interface between operators and automation systems in demanding industrial environments. As part of ABB’s extended HMI portfolio, ABB XVC517AE10 3BHB004744R0010 combines a 10.1-inch high-resolution display with powerful processing capabilities, enabling intuitive monitoring and control of machinery, production lines, and process systems.

ABB XVC517AE10 3BHB004744R0010 features a resistive touchscreen that operates reliably even with gloves, making it suitable for harsh environments where operators may wear protective gear. Its robust communication options ensure seamless integration with PLCs, DCS systems, and field devices, while its IP65 front protection rating guards against dust and water ingress. Whether deployed in manufacturing, energy, or process industries, ABB XVC517AE10 3BHB004744R0010 provides operators with real-time data visualization, alarm management, and manual control capabilities, enhancing operational efficiency and reducing response times to process anomalies.

Core advantages and technical highlights

Durable touch interface for industrial use: The 10.1-inch resistive touchscreen of ABB XVC517AE10 3BHB004744R0010 is designed to withstand frequent use, chemical exposure, and mechanical impact—common in industrial settings. Unlike capacitive screens, it responds reliably to gloved hands, a critical feature in food processing plants or pharmaceutical facilities where operators wear latex gloves. The screen’s anti-glare coating ensures visibility even under bright factory lighting, while its 1024 × 600 resolution delivers sharp graphics for clear data visualization.

Flexible connectivity options: Equipped with dual Ethernet ports, USB interfaces, and an RS485 port, ABB XVC517AE10 3BHB004744R0010 supports seamless integration with diverse automation systems. Its compatibility with protocols like Modbus TCP, PROFIBUS DP, and OPC UA allows communication with ABB’s AC500 PLCs, third-party controllers, and SCADA systems. In a automotive assembly line, this versatility enables the HMI to display real-time data from welding robots (via PROFIBUS) and conveyor systems (via Modbus TCP) on a single screen, providing operators with a unified view of the production process.

Rugged design for harsh environments: With an IP65 front rating, ABB XVC517AE10 3BHB004744R0010 resists water jets and dust ingress, making it suitable for washdown areas in food and beverage plants. Its operating temperature range (-10°C to 50°C) ensures reliable performance in cold storage facilities and hot industrial zones, such as foundries. The panel’s aluminum bezel and reinforced housing withstand vibration and shock, complying with IEC 60068-2 standards for mechanical endurance—critical for mobile machinery or production lines with high vibration levels.

Powerful processing for complex visuals: The ARM Cortex-A9 processor (1 GHz) and 1 GB RAM enable ABB XVC517AE10 3BHB004744R0010 to render dynamic graphics, trend charts, and multi-layered screens without lag. In a water treatment plant, this processing power allows the HMI to display real-time flow rates, pressure readings, and valve positions alongside historical trend data, helping operators identify process patterns and optimize performance. The 8 GB flash storage supports offline data logging, ensuring critical information is retained even during network outages.

Typical application scenarios

In a pulp and paper mill, ABB XVC517AE10 3BHB004744R0010 is installed at the paper machine control station, providing operators with a comprehensive view of the production process. The HMI displays live data from the PM633 PLC, including sheet thickness, moisture content, and reel speed, with 4-20 mA control signals from the DSAO120 module visualized as valve position indicators. Operators use the touchscreen to adjust setpoints for the drying section, with the HMI sending commands via Modbus TCP to the PLC. The IP65 front protection ensures the panel remains operational during periodic washdowns to remove paper dust.

In a solar power inverter station, ABB XVC517AE10 3BHB004744R0010 monitors and controls multiple inverters, displaying DC input voltage, AC output power, and efficiency metrics. The HMI’s Ethernet ports connect to the inverters via EtherNet/IP, while its RS485 port links to a weather station for irradiance data. Operators use the touchscreen to start/stop inverters, view fault logs, and access performance reports—all critical for maximizing energy production. The panel’s wide temperature tolerance ensures reliable operation in the unheated inverter shelter, where temperatures range from -5°C in winter to 45°C in summer.

ABB XVC517AE10 3BHB004744R0010

Related model recommendations

ABB XVC430AE01: A 7-inch compact HMI that complements ABB XVC517AE10 3BHB004744R0010 for decentralized control stations.

ABB PM633: A PLC that communicates with ABB XVC517AE10 3BHB004744R0010 to exchange real-time process data.

ABB DSAO120 57120001-EY: An analog output module whose signals are visualized and controlled via ABB XVC517AE10 3BHB004744R0010.

ABB CI858-1 3BSE018137R1: A communication module that enhances data exchange between ABB XVC517AE10 3BHB004744R0010 and Ethernet-based systems.

ABB PPE091A101 3BHE044481R0101: A redundant 24 V DC power supply ensuring uninterrupted operation of ABB XVC517AE10 3BHB004744R0010.

ABB 200900-004: A terminal block used to terminate power and communication cables for ABB XVC517AE10 3BHB004744R0010 in control panels.

Installation, commissioning and maintenance instructions

Installation preparation: Mount ABB XVC517AE10 3BHB004744R0010 in a panel cutout using the provided mounting brackets, ensuring a watertight seal (IP65) with the included gasket. Torque the mounting screws to 1.5 Nm to prevent water ingress. Connect 24 V DC power using 0.75 mm² shielded cable, protected by a 1A fuse. Wire Ethernet and RS485 communication cables (shielded) to their respective ports, grounding shields at both ends. Configure network settings and protocol parameters via the HMI’s setup menu before commissioning. Power off the system during installation to avoid electrical hazards.

Maintenance suggestions: Inspect ABB XVC517AE10 3BHB004744R0010 monthly for dust accumulation on the screen and ventilation slots. Clean the touchscreen with a soft, damp cloth and mild detergent—avoid abrasive cleaners or solvents. Check cable connections quarterly for tightness, especially in high-vibration environments. Back up configuration data and logged data to a USB drive quarterly. Update firmware annually via Ethernet or USB to access the latest features and security patches. If the screen becomes unresponsive or communication fails, verify power and network connections before replacing components—use only ABB-certified parts to maintain protection ratings.

Service and guarantee commitment

ABB XVC517AE10 3BHB004744R0010 is backed by a 3-year warranty from installation, covering manufacturing defects and ensuring compliance with published performance standards. ABB’s HMI technical support team provides response within 4 hours for critical issues, with remote troubleshooting available 24/7 to minimize downtime. On-site service is available within 72 hours in major industrial regions for hardware repairs or complex configuration issues.

The warranty includes free access to HMI configuration software (e.g., ABB Panel Builder) and firmware updates. Extended service contracts offer annual preventive maintenance, screen calibration, and priority support, ensuring the panel maintains optimal performance throughout its 10-year design lifespan. ABB’s commitment to quality underscores confidence in ABB XVC517AE10 3BHB004744R0010 as a reliable operator interface in industrial automation systems.