Description

| Parameter name | Parameter value |

| Product model | XVC724BE101 3BHE009017R0101 |

| Manufacturer | ABB |

| Product category | Drive control module |

| Input voltage range | 100 – 240 VAC, ±10% |

| Output current capacity | Up to 10 A per channel |

| Dimensions (LxWxH) | 150 mm x 100 mm x 50 mm |

| Interface type | Analog inputs (4 – 20 mA), digital I/O (24 VDC), Ethernet |

| Communication protocol | Modbus TCP/IP, Profinet |

| Operating temperature | -20°C to +60°C |

| Storage temperature | -40°C to +85°C |

| Installation method | DIN – rail or panel – mountable |

| Motor speed control accuracy | ±0.1% of rated speed |

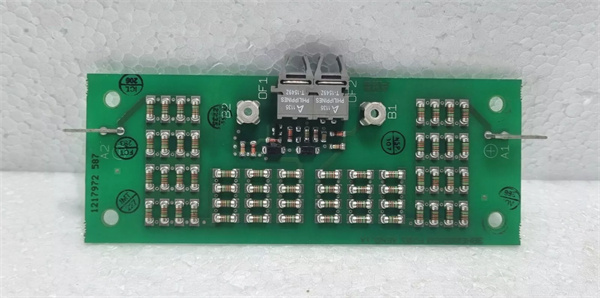

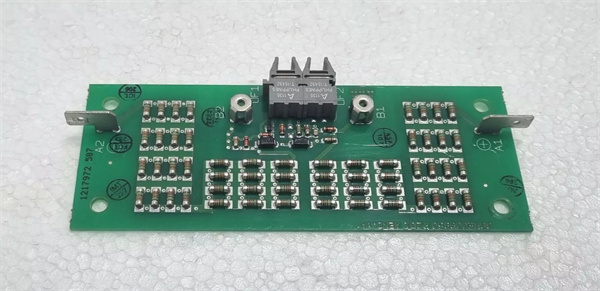

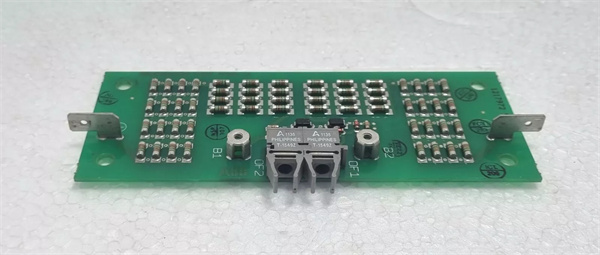

ABB XVC724BE101 3BHE009017R0101

Product introduction

The ABB XVC724BE101 3BHE009017R0101 is a high – performance drive control module, designed to be a cornerstone in industrial automation systems. As part of ABB’s advanced control module lineup, it brings a wealth of capabilities to the table. This module is engineered to precisely regulate the operation of high – power servo motors, ensuring that they deliver the required speed and torque with utmost accuracy.

In industrial automation, accurate motor control is crucial. The XVC724BE101 3BHE009017R0101 serves as the bridge between the control system and the servo motors. It interprets control commands from the 上位机 and translates them into appropriate electrical signals to drive the motors. By maintaining tight control over motor parameters, it enables smooth and efficient operation of machinery, reducing energy consumption and enhancing productivity.

Core advantages and technical highlights

Precise motor control

The ABB XVC724BE101 3BHE009017R0101 offers an outstanding motor speed control accuracy of ±0.1% of the rated speed. This precision is achieved through a high – performance PWM drive circuit. For applications where tight tolerance in motor speed is required, such as in precision manufacturing processes, this module ensures that the motors operate within the exact specifications, minimizing product defects.

Robust communication capabilities

Equipped with Ethernet interface and support for Modbus TCP/IP and Profinet protocols, the XVC724BE101 3BHE009017R0101 enables seamless integration into industrial networks. It can communicate with other control devices, sensors, and actuators in real – time. This allows for centralized monitoring and control, making it easier to manage complex automation systems. For example, it can quickly receive updated control parameters from a central PLC and adjust the motor operation accordingly.

Wide operating temperature range

With an operating temperature range of – 20°C to +60°C, the module can withstand harsh industrial environments. Whether it’s deployed in a cold storage facility or a hot manufacturing plant, the ABB XVC724BE101 3BHE009017R0101 maintains its performance. This robustness reduces the need for additional environmental control measures, saving costs and increasing the reliability of the overall system.

Typical application scenarios

In the manufacturing industry, the ABB XVC724BE101 3BHE009017R0101 is widely used in automated production lines. For instance, in a high – precision electronics assembly line, the module controls the servo motors that position components with extreme accuracy. Its precise speed and torque control ensure that delicate electronic parts are placed correctly, reducing the risk of misalignment and improving product quality.

In the packaging industry, it plays a vital role in controlling the motors of packaging machines. The ability to adjust motor speed and torque in real – time allows for seamless operation when handling different types of packaging materials. Whether it’s thin plastic films or thick cardboard boxes, the XVC724BE101 3BHE009017R0101 ensures that the packaging process is efficient and accurate, minimizing material waste.

In robotic applications, this module is used to control the motors of robotic arms. The precise control capabilities enable the robotic arms to perform complex tasks such as pick – and – place operations with high repeatability. This is essential in industries like automotive manufacturing, where robotic arms need to handle heavy parts with great precision.

ABB XVC724BE101 3BHE009017R0101

Related model recommendations

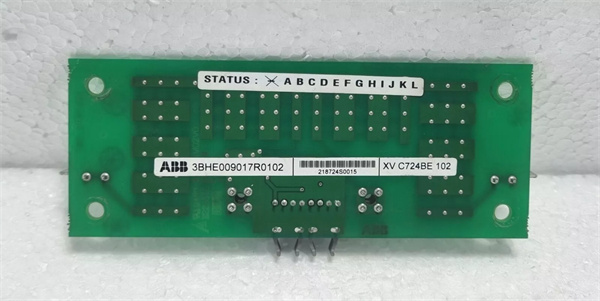

XVC724BE102 3BHE009017R0102: It belongs to the same series as the XVC724BE101 3BHE009017R0101. It has similar functions but may have some minor differences in terms of output current capacity or communication options, suitable for applications with slightly different requirements.

ACS880 – 01 – 01A7 – 4: ABB’s variable – speed drive that can be paired with the XVC724BE101 3BHE009017R0101 to provide a comprehensive motor control solution. It complements the module by further optimizing the motor’s performance in terms of energy efficiency and speed regulation.

PM864AK01: An ABB control module that can work in tandem with the XVC724BE101 3BHE009017R0101 in larger industrial control systems. It provides additional control and monitoring functions, enhancing the overall system’s capabilities.

CI854A 3BSE030221R1: A PROFIBUS DP module that can be integrated with the XVC724BE101 3BHE009017R0101 to expand its communication options, especially useful in systems that rely on PROFIBUS for data transfer.

DI810 3BSE008549R1: A digital input module that can be used in conjunction with the XVC724BE101 3BHE009017R0101 to provide more input channels for sensors and switches, enabling more comprehensive control in complex automation setups.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the ABB XVC724BE101 3BHE009017R0101, ensure that the installation environment meets the specified temperature and humidity requirements. Use appropriate tools such as screwdrivers and wire strippers. When connecting the power supply, make sure to follow the correct polarity to avoid damaging the module. Mount the module securely on the DIN – rail or panel, ensuring that there is sufficient clearance for ventilation.

Commissioning

Power on the module and use ABB’s dedicated commissioning software to configure the parameters. Set the motor – related parameters such as rated voltage, current, and speed. Calibrate the analog inputs and digital I/O to ensure accurate signal detection. Test the communication with other devices on the network to verify proper integration.

Maintenance suggestions

For daily maintenance, regularly check for loose connections and signs of overheating. Clean the module from dust and debris to maintain proper ventilation. In case of a malfunction, use the diagnostic tools provided by ABB to identify the problem. If a component needs replacement, use genuine ABB spare parts, such as replacement connectors or circuit boards, to ensure the continued high – performance operation of the XVC724BE101 3BHE009017R0101.

Service and guarantee commitment

ABB stands firmly behind the XVC724BE101 3BHE009017R0101 with a comprehensive service and guarantee commitment. The product comes with a standard 2 – year warranty, covering any defects in materials and workmanship. During this period, ABB will provide free replacement of faulty modules and offer 24/7 technical support.

Customers can access ABB’s online resources, including detailed user manuals, software updates, and troubleshooting guides. ABB also offers optional on – site installation and commissioning services, as well as training programs for operators and maintenance personnel. This ensures that customers can make the most of the module’s capabilities and minimize downtime, reflecting ABB’s confidence in the quality of the XVC724BE101 3BHE009017R0101 and its commitment to customer satisfaction.