Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | XVC767AE102 |

| Manufacturer | ABB |

| Product category | High-density I/O termination unit (Advant OCS systems) |

| Number of channels | 32 mixed analog/digital channels |

| Terminal type | Spring clamp (accepts 0.2-2.5 mm² wires) |

| Signal compatibility | 4-20 mA, 0-10 V, 24 V DC digital signals |

| Isolation | 2.5 kV AC (channel-to-bus) |

| Operating voltage | 24 V DC ±10% (auxiliary power) |

| Power consumption | ≤ 2 W |

| Operating temperature | 0°C to +60°C |

| Dimensions (W×H×D) | 160 mm × 180 mm × 90 mm |

| Installation method | DIN rail mounting (35 mm standard rail) |

| Protection class | IP20 |

| Diagnostic features | Power LED, channel group status indicators |

| Compliance | IEC 61131-2, CE, UL 508 |

| Compatible systems | ABB Advant OCS, AC400 controller, DSTA131 digital input modules, CMA136 analog modules |

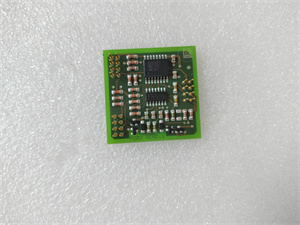

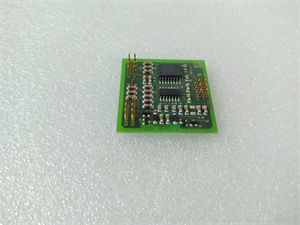

ABB XVC767AE102

Product introduction

The XVC767AE102 is a high-density I/O termination unit from ABB, designed to streamline wiring in Advant Open Control System (OCS) architectures. As a critical interface between field devices and I/O modules, it provides organized termination for 32 mixed analog and digital signals, reducing cabinet space requirements and simplifying installation.

With spring clamp terminals that accept a wide range of wire sizes, XVC767AE102 offers fast, tool-free wiring—ideal for high-channel-count applications where installation time is critical. Its compatibility with both analog (4-20 mA, 0-10 V) and digital (24 V DC) signals eliminates the need for separate termination units, making it a versatile choice for complex industrial systems. Whether paired with DSTA131 digital input modules or CMA136 analog modules, XVC767AE102 ensures reliable signal transmission, enhancing system maintainability and reducing wiring errors in process control environments.

Core advantages and technical highlights

High-density design

XVC767AE102’s 32-channel capacity in a compact housing reduces cabinet footprint by up to 40% compared to lower-density termination units. In a chemical plant control room with hundreds of I/O points, this density allows engineers to terminate all signals from a reactor section in a single unit, simplifying cable management and reducing the risk of cross-connections.

Tool-free wiring

Spring clamp terminals enable quick wire insertion and removal without screwdrivers, cutting installation time by 50% compared to screw-clamp designs. During a plant expansion, technicians can connect 32 wires to XVC767AE102 in under 10 minutes, minimizing downtime during system upgrades. The terminals also maintain consistent clamping force, preventing vibration-induced loose connections in machinery applications.

Mixed signal support

By accommodating both analog and digital signals, XVC767AE102 eliminates the need for separate termination units in mixed I/O environments. In a water treatment plant’s filtration system, it terminates:

4-20 mA from pressure transmitters (analog)

24 V DC from flow switches (digital)

0-10 V from level sensors (analog)

This integration simplifies spare parts inventory and reduces training requirements for maintenance teams.

Typical application scenarios

In a pulp and paper mill’s paper machine control system, XVC767AE102 serves as the central termination point for a critical production section:

Connects 16 digital inputs (from DSTA131 modules) monitoring bearing temperature switches and belt alignment sensors.

Terminates 16 analog signals (to CMA136 modules) from stock flow transmitters and steam pressure sensors.

The unit’s organized layout allows technicians to quickly trace wires during troubleshooting, reducing unplanned downtime when a sensor fault occurs. Its spring terminals withstand the mill’s vibration, ensuring reliable connections in this dynamic environment.

In a food and beverage bottling plant’s filling line, XVC767AE102 simplifies wiring for:

24 V DC digital signals from bottle detection sensors and cap presence switches.

4-20 mA analog signals from fill level transmitters and pressure regulators.

Paired with the AC400 controller, it provides a clean, organized interface that simplifies validation audits required by food safety regulations. The unit’s compact size also fits easily in the space-constrained cabinets typical of packaging machinery.

ABB XVC767AE102

Related model recommendations

XVC768115 3BHB007211R115: 16-channel termination unit, ideal for smaller systems complementary to XVC767AE102.

DSTA131: Digital input module that connects to field devices via XVC767AE102’s terminals.

CMA136: Analog input module paired with XVC767AE102 for processing 4-20 mA/0-10 V signals.

TB820V2: Terminal base compatible with XVC767AE102 for S800 I/O module integration.

XVC769AE101: 64-channel high-density variant of XVC767AE102 for large-scale installations.

1SVR011700R0000: 24 V DC power supply for energizing auxiliary circuits connected to XVC767AE102.

IMDSO14: Digital output module that uses XVC767AE102 for field wiring termination.

XVC767BE101: Screw-clamp version of XVC767AE102 for applications requiring higher clamping force.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing XVC767AE102, ensure the DIN rail is securely mounted and grounded. Clean the installation area to remove dust or debris that could interfere with connections. Mount the unit on a 35 mm DIN rail, leaving 50 mm clearance above and below for wiring access. Verify that wire sizes (0.2-2.5 mm²) match terminal specifications. For analog signals, use shielded twisted-pair cables and connect shields to the unit’s grounding terminal. Label all wires according to the system wiring diagram before insertion into spring terminals—press the orange lever to open the terminal, insert stripped wire (8-10 mm), and release the lever to secure.

Maintenance suggestions

Inspect XVC767AE102 quarterly for loose wires or damaged terminals. Check the power LED to confirm auxiliary power is present. For troubleshooting, use a multimeter to verify signal continuity between field devices and the unit’s output terminals. If a terminal fails, replace the entire unit (spring terminals are not field-serviceable). When replacing XVC767AE102, document wire positions or use a wiring harness adapter to maintain connections, minimizing downtime. Store spare units in dry, dust-free conditions to prevent terminal corrosion.

Service and guarantee commitment

The XVC767AE102 is backed by a 2-year warranty, covering defects in materials and workmanship under normal operating conditions. ABB’s technical support team provides guidance on integration with Advant OCS components like DSTA131 and CMA136, including wiring best practices and compatibility verification.

Customers receive access to detailed installation manuals and terminal layout diagrams for XVC767AE102. ABB’s global distribution network ensures quick availability of replacement units, minimizing downtime in critical control systems. For large projects, ABB offers pre-termination services to accelerate on-site installation, ensuring XVC767AE102 units arrive ready for immediate connection to field devices and I/O modules.