Description

| Parameter name | Parameter value |

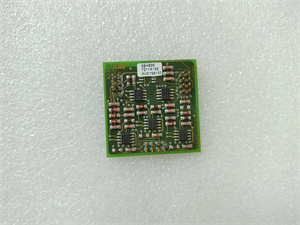

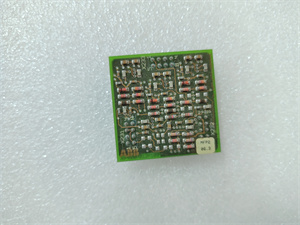

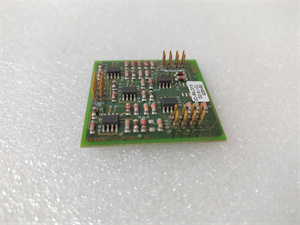

| Product model | 07KT98 GJR5253100R0278 |

| Manufacturer | ABB |

| Product category | Programmable Logic Controller (PLC) module for industrial automation |

| Communication interfaces | Ethernet TCP/IP, CANopen master |

| Analog inputs | 8 channels – Voltage ranges: 0 – +5V, -5 – +5V, 0 – +10V, -10 – +10V – Current ranges: 0 – 20mA, 4 – 20mA – RTD: PT100 (2 or 3 wire) – Resolution: 10-bit (for 0 – +5V, -5 – +5V), 11-bit (for 0 – +10V, -10 – +10V), 12-bit (for 0 – 20mA, 4 – 20mA, PT100) |

| Analog outputs | 4 channels – Voltage range: -10 – +10V (11-bit + sign) – Current range: 0 – 20mA (12-bit) |

| Digital inputs (DC 24V) | 24 |

| Digital outputs (DC 24V) | 16 |

| Digital configurable I/Os | 8 |

| Memory size – user data | 1000 kb (Flash EPROM) |

| Memory size – user program | 1000 kb (Flash EPROM, non-volatile RAM, SMC) |

| Hardware counters | 2 (with maximum input frequency of 50 kHz) |

| Output current | 0.5 A |

| Output voltage | 24 V DC |

| Primary voltage | 24 V |

| Operating temperature | 0°C to +55°C |

| Storage temperature | -25°C to +75°C |

| Programming software | AC 1131 |

| Serial ports | Serial port 1: RS232 (for programming, Modbus master or slave) Serial port 2: RS232 (Modbus master or slave, ASCII) |

| Terminal type | Screw terminals, pluggable |

| Compliance | Complies with relevant industry standards for reliable operation |

| Application areas | Industrial automation, process control systems, building automation, manufacturing and production facilities |

ABB XVC768102 3BHB007211R102

Product introduction

The 07KT98 GJR5253100R0278 is a versatile and reliable PLC module from ABB, designed to play a crucial role in industrial automation setups. As part of ABB’s AC 31 series, this module serves as a fundamental building block for creating efficient and intelligent control systems.

This module’s ability to handle a variety of analog and digital inputs and outputs makes it suitable for a wide range of applications. It can interface with sensors, actuators, and other devices, translating real-world signals into digital data that can be processed by the control system. The integrated Ethernet TCP/IP and CANopen master interfaces enable seamless communication with other networked devices, facilitating the exchange of data between different components of an industrial network. This makes it an ideal choice for modern industrial environments where connectivity and data sharing are essential for optimized operations.

Core advantages and technical highlights

Multi-faceted I/O capabilities: With 8 analog input channels supporting multiple voltage and current ranges, as well as PT100 RTD inputs, the 07KT98 GJR5253100R0278 can interface with a diverse array of sensors. In a chemical processing plant, it can monitor temperature (using PT100 sensors), pressure (via 4 – 20mA transducers), and flow rate (0 – 20mA sensors) simultaneously. The 4 analog output channels can then be used to control actuators such as valves or variable frequency drives, ensuring precise process control.

The 24 digital inputs and 16 digital outputs, along with 8 configurable I/Os, offer flexibility in handling discrete signals. In a packaging line, digital inputs can detect the presence of products, while digital outputs can control the operation of motors, solenoids, and other discrete devices. This comprehensive I/O set enables the module to manage complex industrial processes with ease.

High – speed data processing and communication: The module’s memory architecture, with 1000 kb of user data and user program memory, allows for efficient storage and execution of control algorithms. The use of Flash EPROM and non-volatile RAM ensures data integrity even during power outages. In a high – speed bottling plant, the 07KT98 can quickly process incoming sensor data and execute control commands, ensuring seamless bottle filling and capping operations.

The Ethernet TCP/IP and CANopen master interfaces provide high – speed data transmission. The Ethernet interface, in particular, enables fast and reliable communication with other devices on the network. In a large – scale manufacturing facility, the module can communicate with supervisory control and data acquisition (SCADA) systems, other PLCs, and human – machine interfaces (HMIs) in real – time. This allows for centralized monitoring and control of the entire production process, improving overall efficiency and productivity.

Reliable operation in harsh environments: Designed to operate within a temperature range of 0°C to +55°C and store between -25°C to +75°C, the 07KT98 GJR5253100R0278 can withstand the harsh conditions often found in industrial settings. In a steel mill, where temperatures can be extremely high and the environment is filled with dust and vibrations, this module can continue to function reliably. Its robust design and compliance with industry standards ensure long – term stability and minimize the risk of downtime.

Typical application scenarios

Industrial automation: In an automotive assembly line, the 07KT98 GJR5253100R0278 can be used to control the movement of robotic arms. The analog inputs can receive feedback from position sensors on the arms, while the digital outputs can control the motors that drive the arm’s joints. The Ethernet interface allows for communication with the central control system, which can coordinate the actions of multiple robotic arms to ensure smooth and efficient vehicle assembly.

Process control systems: A water treatment plant can utilize this module to control the entire water treatment process. The analog inputs can monitor parameters such as water pH, turbidity, and chlorine levels. Based on this data, the analog outputs can adjust the dosage of chemicals, while the digital outputs can control pumps, valves, and other equipment. The CANopen master interface can be used to communicate with intelligent sensors and actuators in the field, enabling a more distributed and efficient control system.

Building automation: In a large commercial building, the 07KT98 can be used to control the heating, ventilation, and air – conditioning (HVAC) system. The analog inputs can measure temperature, humidity, and air quality, while the digital outputs can control the operation of fans, dampers, and heating/cooling units. The Ethernet interface allows for remote monitoring and control of the HVAC system, either from a central building management system or via the internet, enabling energy – efficient operation and improved comfort for building occupants.

ABB XVC768102 3BHB007211R102

Related model recommendations

07KT97 GJR5253100R0277: A lower – cost alternative with fewer I/O channels. It has 4 analog input channels and a reduced number of digital I/Os. Ideal for small – scale industrial applications or simple building automation projects where the complexity of I/O requirements is limited.

07KT99 GJR5253100R0279: An upgraded version with more extensive I/O capabilities. It offers 16 analog input channels and additional digital I/Os. Suited for large – scale industrial plants or complex process control systems where a high volume of data needs to be processed and controlled.

AC31 – CPU – 113: ABB’s AC 31 series central processing unit (CPU) that pairs perfectly with the 07KT98. The CPU provides the computational power to execute the control programs running on the 07KT98 module, ensuring smooth and efficient operation of the overall control system.

HMI – 500: A touch – screen human – machine interface that can be connected to the 07KT98 via its Ethernet interface. Operators can use this HMI to monitor real – time data, adjust control parameters, and receive alarms. It simplifies the interaction between operators and the control system, improving the overall usability and efficiency of the industrial process.

ETHER – CAB – KIT: A dedicated Ethernet cable kit for the 07KT98. This kit includes high – quality shielded Ethernet cables and connectors, ensuring reliable and high – speed data transmission between the module and other networked devices.

CAN – CAB – KIT: A CANopen cable kit designed for the 07KT98’s CANopen master interface. It provides the necessary cables and connectors for connecting to CANopen – compatible devices in the field, enabling seamless communication within the CANopen network.

Installation, commissioning and maintenance instructions

Installation preparation: Mount the 07KT98 GJR5253100R0278 on a suitable DIN rail using the provided mounting brackets. Ensure that there is sufficient clearance around the module for proper ventilation. Connect the power supply wires (24 V DC) to the designated terminals, making sure to observe the correct polarity. Use shielded cables for connecting analog and digital I/O signals to minimize interference. For Ethernet and CANopen connections, use the appropriate cables and connectors, ensuring that the connections are secure.

Commissioning: First, verify all physical connections. Power on the module and check the status LEDs to ensure that the module has powered up correctly. Use ABB’s AC 1131 programming software to load the control program onto the module. Configure the communication settings for Ethernet and CANopen interfaces, including IP addresses, subnet masks, and CANopen node IDs. Test the analog and digital I/O channels by connecting known sensors and actuators and monitoring the data received and sent by the module.

Maintenance suggestions: Regularly inspect the module for any signs of physical damage, such as loose connections or damaged terminals. Clean the module periodically to remove dust and debris, which can affect its performance. Check the status LEDs regularly to identify any potential issues. For example, a flashing red LED may indicate an error in the module. Use the AC 1131 programming software to perform diagnostic tests, such as checking the integrity of the memory and communication interfaces. Replace any faulty components promptly. ABB provides a list of recommended spare parts, including replacement I/O modules, power supplies, and communication cards.

Service and guarantee commitment

ABB offers a 12 – month warranty on the 07KT98 GJR5253100R0278, covering defects in materials and workmanship. During this period, if the module fails due to a manufacturing defect, ABB will provide free repair or replacement. ABB also offers 24/7 technical support to assist customers with any issues related to the module. Their team of experts can provide guidance on installation, commissioning, and troubleshooting. Additionally, ABB provides access to software updates and application notes through their online support portal, ensuring that customers can keep their modules up – to – date and operating at peak performance.