Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | XVC768AE101 |

| Manufacturer | ABB |

| Product Category | Terminal block assembly (for S800 I/O modules, digital signal termination) |

| Number of Terminals | 32 terminals (16 input/output pairs) |

| Wire Size Range | 0.5 mm² to 1.5 mm² (solid or stranded with ferrule) |

| Connection Type | Screw terminals (M3 screws, torque range: 0.5-0.7 Nm) |

| Rated Voltage | 600 V AC/DC |

| Rated Current | 10 A |

| Isolation | Compatible with 2.5 kV AC isolated I/O modules |

| Housing Material | Polyamide 6.6 (UL94 V0 flame rating) |

| Operating Temperature | -40°C to +70°C |

| Dimensions (W×H×D) | 45 mm × 150 mm × 110 mm |

| Installation Method | DIN rail mounting (35 mm standard rail), compatible with S800 I/O mounting rails |

| Protection Features | Finger-safe design (IP20), flame-retardant insulation |

| Compliance | IEC 61131-2, CE, UL 508 |

| Compatible Systems | ABB S800 I/O modules (DO880, DI880, AO815), AC800M controller, TB820V2 terminal bases |

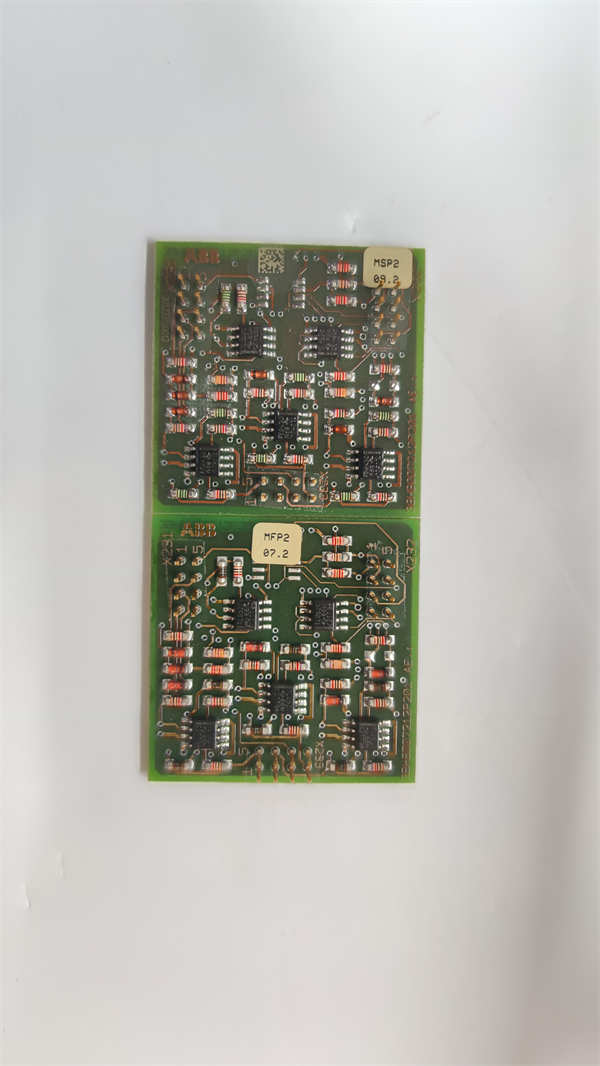

ABB XVC768AE101

Product Introduction

The XVC768AE101 is a high-density terminal block assembly from ABB, designed specifically for terminating digital signals in S800 I/O systems. As a critical wiring component in industrial automation, it provides a structured interface between field devices (sensors, actuators, switches) and S800 I/O modules (such as DO880 digital outputs and DI880 digital inputs), simplifying wiring management in control cabinets.

With 32 terminals (16 input/output pairs) and support for 0.5-1.5 mm² wires, this terminal block assembly streamlines connections in high-density I/O configurations. Its robust polyamide housing and finger-safe design ensure durability and operator safety, while compatibility with ABB’s S800 I/O mounting system enables quick installation and maintenance. Whether used in manufacturing lines, process control panels, or utility substations, the XVC768AE101 enhances wiring organization, reduces installation time, and ensures reliable signal transmission between field devices and the control system.

Core Advantages and Technical Highlights

High-density signal termination

The XVC768AE101 packs 32 terminals into a 45 mm-wide housing, supporting 16 I/O pairs—ideal for high-density S800 I/O configurations. In a automotive assembly line control cabinet with 8 DO880 modules, this density reduces the required DIN rail length by 40% compared to lower-density terminal blocks, freeing space for additional components like surge protectors or fuses.

Seamless S800 I/O integration

Designed specifically for S800 modules, the XVC768AE101 aligns perfectly with DO880 and DI880 modules when mounted on S800 rails, ensuring precise alignment with module connectors. This pre-engineered compatibility eliminates wiring errors during installation, as terminal numbering matches the module’s channel numbering (e.g., Terminal 1 = Channel 1). In a food processing plant’s control system, this alignment simplifies validation audits by ensuring wiring traces directly from field devices to I/O channels.

Robust and safe design

The terminal block’s polyamide 6.6 housing (UL94 V0) resists ignition and maintains structural integrity in high temperatures (-40°C to +70°C). Its finger-safe design (IP20) prevents accidental contact with live terminals during maintenance, reducing the risk of electrical shock. In a chemical plant’s hazardous area control cabinet, this safety feature is critical for technicians working near energized equipment.

Typical Application Scenarios

In a water treatment plant’s pump control panel:

XVC768AE101 assemblies terminate wiring from float switches and pressure sensors to DI880 digital input modules, monitoring pump status and tank levels.

They connect DO880 output modules to pump contactors and valve solenoids, organizing 24 V DC control signals.

The structured terminal layout allows technicians to quickly trace wires from field devices to I/O channels, speeding up troubleshooting when a pump fails to start.

Paired with TB820V2 terminal bases, the assembly forms a secure connection between the S800 modules and field wiring, ensuring reliable operation in humid environments.

In a manufacturing facility’s robotic cell control system:

XVC768AE101 terminal blocks connect proximity sensors (inputs) and gripper solenoids (outputs) to S800 I/O modules.

Their compact size fits into the cell’s space-constrained control cabinet, alongside the AC800M controller.

Color-coded terminal markers (included) identify signal types (e.g., “Emergency Stop,” “Gripper Open”), simplifying reconfiguration when the robot’s task is modified.

Screw terminals with specified torque settings ensure vibration-resistant connections, preventing signal loss in the high-vibration environment near robotic arms.

ABB XVC768AE101

Related Model Recommendations

XVC769AE101: 64-terminal variant of XVC768AE101 for larger I/O configurations.

XVC767AE102: Terminal block assembly for analog signals, compatible with AO815 modules.

DO880: Digital output module that pairs with XVC768AE101 for control signal termination.

DI880: Digital input module whose field wiring is organized by XVC768AE101.

TB820V2: Terminal base required for mounting S800 I/O modules with XVC768AE101.

1SNA605501R1400: ABB marking strips for XVC768AE101, enabling clear identification of signals.

S800 I/O mounting rail: Aluminum rail system that integrates XVC768AE101 with S800 modules.

Installation, Commissioning and Maintenance Instructions

Installation preparation

Mount XVC768AE101 on a 35 mm DIN rail, aligning it with the corresponding S800 I/O module (e.g., DO880) to ensure terminal numbering matches module channels. Secure the assembly with retaining clips to prevent movement. Use 0.5-1.5 mm² wires, stripped to 6-8 mm length, and terminate using M3 screws (torque to 0.5-0.7 Nm). Connect field device wires to the “field” side terminals and module jumper wires to the “module” side terminals, following the numbering scheme (Terminal 1 = Channel 1).

Commissioning steps

Verify all connections are tight and wires are correctly routed (no strain on terminals). Use a multimeter to check continuity between field devices and module terminals, ensuring no cross-connections. Power on the S800 system and confirm that signals pass correctly through the terminal block (e.g., a sensor input triggers the corresponding DI880 channel LED). Label terminals using the included marking strips to identify signal names and functions.

Maintenance suggestions

Inspect XVC768AE101 quarterly for loose screws, wire fraying, or signs of overheating (discoloration). Re-tighten screws to the specified torque if needed, especially in vibration-prone environments. Clean terminals with compressed air to remove dust or debris that could cause tracking. Replace any terminal block with cracked housing or stripped screws immediately, using only ABB-approved spares to maintain compatibility with S800 modules.

Service and Guarantee Commitment

The XVC768AE101 is backed by a 3-year warranty, covering defects in materials and workmanship under normal operating conditions. ABB’s technical support team provides guidance on installation, wiring best practices, and compatibility with S800 I/O modules like DO880 and DI880.

Customers receive access to detailed mounting diagrams and terminal numbering guides for XVC768AE101. ABB ensures global availability of replacement terminal blocks, minimizing downtime for control system maintenance. With a focus on industrial reliability, this terminal block assembly is designed to meet the rigorous demands of automation environments, supported by ABB’s expertise in I/O system integration.