Description

Detailed parameter table

| Parameter name | Parameter value |

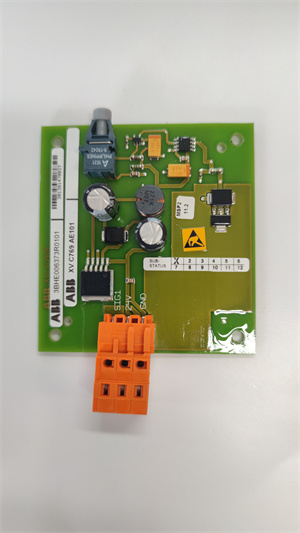

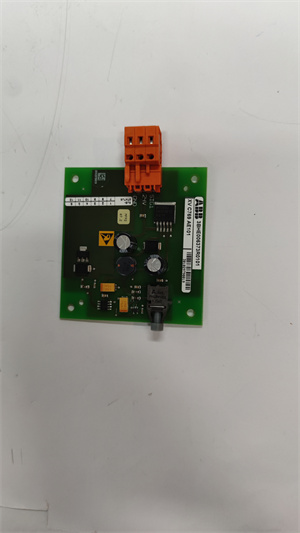

| Product model | XVC769AE101 |

| Manufacturer | ABB |

| Product category | High-density I/O termination unit (Advant OCS and AC800M systems) |

| Number of channels | 64 mixed analog/digital channels (4 groups of 16) |

| Terminal type | Spring clamp (0.14-2.5 mm² wire range) |

| Signal compatibility | 4-20 mA, 0-10 V, 24 V DC digital, thermocouple (Type J/K/T) |

| Isolation | 2.5 kV AC (channel-to-bus, group-to-group) |

| Operating voltage | 24 V DC ±10% (auxiliary power) |

| Power consumption | ≤ 3 W |

| Operating temperature | -25°C to +70°C |

| Dimensions (W×H×D) | 160 mm × 220 mm × 100 mm |

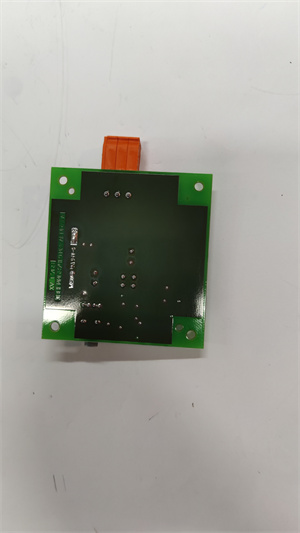

| Installation method | DIN rail mounting (35 mm standard rail) |

| Protection class | IP20 |

| Diagnostic features | Power LED, 4 group status LEDs, fault indication |

| Compliance | IEC 61131-2, CE, UL 508, ATEX Zone 2 |

| Compatible systems | ABB AC800M controller, S800 I/O modules, AO910 analog outputs, DSTA131 digital inputs |

ABB XVC769AE101

Product introduction

The XVC769AE101 is a high-density I/O termination unit from ABB, engineered to streamline wiring in large-scale industrial automation systems. As a central hub for field device connections, it consolidates 64 mixed analog and digital signals into a compact, organized interface, reducing control cabinet footprint by up to 40% compared to standard termination solutions.

Designed for harsh industrial environments, XVC769AE101 features group-based isolation and wide temperature tolerance (-25°C to +70°C), making it suitable for both indoor control rooms and outdoor equipment enclosures. Its spring clamp terminals enable tool-free wiring, cutting installation time by 50% in high-channel-count applications. Whether paired with AO910 analog modules for process control or DSTA131 digital modules for machine monitoring, XVC769AE101 ensures reliable signal transmission, simplifying maintenance and reducing wiring errors in complex systems like oil refineries, power plants, and manufacturing facilities.

Core advantages and technical highlights

Group-isolated design

XVC769AE101 divides 64 channels into 4 isolated groups (16 channels each), preventing cross-contamination between signal types. In a chemical plant’s reactor control system, this isolation ensures 4-20 mA pH sensor signals (Group 1) remain unaffected by 24 V DC motor interlock signals (Group 2), maintaining measurement accuracy critical for process safety.

Extreme environment readiness

With an operating temperature range of -25°C to +70°C and ATEX Zone 2 certification, XVC769AE101 thrives in harsh locations. In an offshore oil platform’s junction box, it reliably terminates signals from subsea pressure transmitters and deck-mounted valves, withstanding salt spray, vibration, and temperature swings that would degrade standard termination units.

Tool-free high-density wiring

Spring clamp terminals accept 0.14-2.5 mm² wires without tools, enabling technicians to terminate 64 channels in under 30 minutes. During a plant shutdown for expansion, this speed allows maintenance teams to rewire a complete process unit’s I/O in a single shift, minimizing production downtime. The terminals’ self-cleaning action also ensures stable connections in dusty environments like cement plants.

Typical application scenarios

In a combined cycle power plant’s turbine control system, XVC769AE101 serves as the central termination point:

Group 1: 16 thermocouple signals from turbine bearings (connected to temperature input modules)

Group 2: 16 4-20 mA signals from pressure transmitters (paired with AO910 modules for control loops)

Group 3: 16 digital inputs from vibration sensors and limit switches (linked to DSTA131 modules)

Group 4: 16 digital outputs to valve actuators and alarm horns

The unit’s group isolation prevents electrical noise from turbine generators affecting sensitive temperature measurements, ensuring accurate condition monitoring and safe turbine operation.

In a large-scale water treatment plant, XVC769AE101 simplifies wiring for:

24 V DC signals from 20 flow switches and 12 level sensors (digital inputs)

4-20 mA signals from 18 chemical dosing pumps and 14 pH transmitters (analog signals)

Mounted in a weatherproof cabinet, its wide temperature range handles seasonal extremes, while tool-free terminals allow quick replacement of faulty sensors during routine maintenance—critical for maintaining water quality compliance.

ABB XVC769AE101

Related model recommendations

XVC767AE102: 32-channel variant of XVC769AE101 for medium-scale systems.

TB820V2: Terminal base adapter that connects XVC769AE101 to S800 I/O modules.

AO910: Analog output module whose signals terminate via XVC769AE101 to field actuators.

DSTA131: Digital input module that receives field signals through XVC769AE101.

CI840A: Profibus module that communicates with controllers using data from XVC769AE101-terminated devices.

XVC770BE101: Explosion-proof version of XVC769AE101 for Zone 1 hazardous areas.

1SVR011718R2500: 24 V DC power supply that energizes XVC769AE101 and peripheral devices.

IMDSO14: Digital output module that pairs with XVC769AE101 for control signal distribution.

Installation, commissioning and maintenance instructions

Installation preparation

Mount XVC769AE101 on a 35 mm DIN rail in a clean, dry enclosure, leaving 50 mm clearance for wiring. Verify ambient temperature stays within -25°C to +70°C and relative humidity <95% (non-condensing). Use shielded twisted-pair cable for analog signals, grounding shields at both ends. For wiring, strip conductors 8-10 mm, press the orange lever to open the terminal, insert wire, and release—no tools required. Separate analog and digital signals into different groups as per the wiring diagram. Connect auxiliary 24 V DC power last, ensuring correct polarity to avoid damage.

Maintenance suggestions

Inspect XVC769AE101 quarterly for loose wires or corrosion—check group LEDs for faults. Clean terminals annually with compressed air (2-3 bar) to remove dust. Test signal continuity between field devices and module connectors using a multimeter. If a group LED shows fault, isolate by disconnecting channels sequentially to find the source. Replace XVC769AE101 as a unit if terminals fail (not field-repairable). When replacing, use a wiring template to map connections, minimizing reconfiguration time. Store spares in anti-static packaging at 10-30°C.

Service and guarantee commitment

XVC769AE101 comes with a 3-year warranty, covering defects in materials and workmanship. ABB’s technical team provides on-site support for integration with AC800M systems, including wiring schematics and compatibility checks with modules like AO910 and DSTA131.

Customers receive access to online training modules on XVC769AE101 installation and maintenance. ABB guarantees 48-hour delivery of replacement units for critical applications, supported by global distribution centers. With dedicated application engineers available 24/7, users get expert guidance on maximizing system reliability—backed by ABB’s 130+ years of industrial automation expertise.

Full 12-month warranty on all components

Dedicated after-sales support

Same-day dispatch on 1000s of parts

All units are fully tested

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide Full 12-month warranty on all components

Full 12-month warranty on all components