Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | XVC769AE101 3BHE006373R0101 |

| Manufacturer | ABB |

| Product category | High-density I/O termination unit (Advant OCS system) |

| Number of channels | 32 mixed analog/digital channels |

| Signal compatibility | 4-20 mA, 0-10 V, 24 V DC digital signals, thermocouple (J/K/T) |

| Isolation voltage | 2.5 kV AC (channel-to-bus, channel-to-channel) |

| Operating voltage | 24 V DC ±10% |

| Power consumption | ≤ 5 W |

| Operating temperature | -20°C to +70°C |

| Dimensions (W×H×D) | 160 mm × 220 mm × 90 mm |

| Installation method | DIN rail mounting (35 mm standard rail) with locking clips |

| Protection class | IP20 |

| Diagnostic features | Channel status LEDs, power indicator, fault alarm output |

| Terminal type | Spring clamp (accepts 0.2-2.5 mm² wires) |

| Compliance | IEC 61131-2, CE, UL 508 |

| Compatible systems | ABB Advant OCS, AC400 controller, CMA136 3DDE300416 analog module, IMDSO14 digital output module |

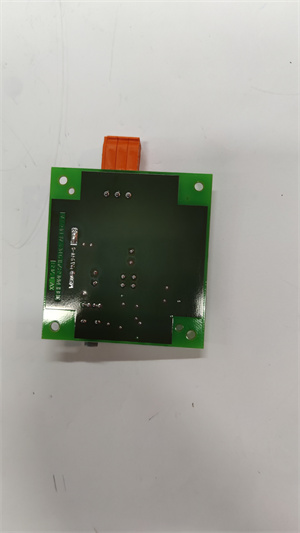

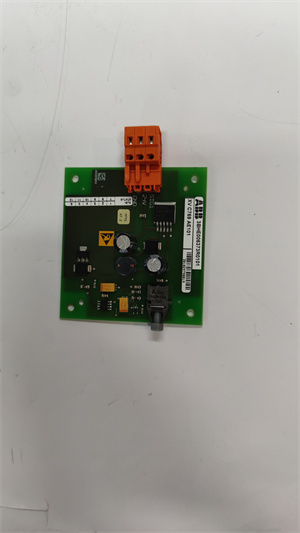

ABB XVC769AE101 3BHE006373R0101

Product introduction

The XVC769AE101 3BHE006373R0101 is a high-density I/O termination unit from ABB, engineered for Advant Open Control Systems (OCS) to serve as a centralized connection hub between field devices and control system modules. This unit streamlines wiring in complex automation setups by consolidating 32 channels of analog (4-20 mA, thermocouples) and digital (24 V DC) signals, eliminating the need for multiple discrete terminal blocks.

As a critical interface component, XVC769AE101 3BHE006373R0101 provides robust 2.5 kV isolation to protect sensitive control electronics from electrical noise and ground loops—common in industrial environments with heavy machinery. Its spring clamp terminals ensure vibration-resistant connections, reducing maintenance needs in applications like chemical processing or power generation. Whether paired with CMA136 3DDE300416 for analog signal processing or IMDSO14 for digital control, XVC769AE101 3BHE006373R0101 enhances system reliability while simplifying installation and troubleshooting.

Core advantages and technical highlights

High-density design

With 32 channels in a 160 mm width, XVC769AE101 3BHE006373R0101 reduces cabinet space requirements by up to 50% compared to lower-density terminal units. In a water treatment plant’s DCS cabinet, this allows integration of 32 field signals (16 pressure transmitters, 16 valve position switches) in half the space, freeing room for expansion modules. The compact footprint also minimizes cable routing distance, lowering signal loss in long runs.

Spring clamp terminals

The unit’s spring clamp connections (0.2-2.5 mm² wires) enable tool-free wiring, cutting installation time by 30% versus screw terminals. In a pharmaceutical batch plant, where frequent reconfiguration is needed for different recipes, technicians can quickly disconnect and reconnect sensors without tools—reducing changeover downtime. The clamps maintain consistent 0.6 Nm contact force, preventing loose connections in vibrating environments.

Integrated diagnostics

Channel-level LEDs provide instant visual confirmation of signal presence, while a collective fault output alerts the controller to wiring issues. In a pulp mill’s boiler control loop, a red LED on XVC769AE101 3BHE006373R0101 immediately identifies a broken thermocouple wire, allowing maintenance to target repairs—avoiding the 2-hour 排查 of traditional terminal blocks.

Typical application scenarios

In a large-scale fertilizer production plant, XVC769AE101 3BHE006373R0101 serves as the termination hub for a urea synthesis reactor control system:

- 12 channels connect K-type thermocouples monitoring reactor temperatures (300-400°C)

- 8 channels handle 4-20 mA signals from pressure transmitters (100-500 psi)

- 12 channels terminate 24 V DC digital signals from safety interlocks (valve position, emergency stops)

Wires from field devices terminate at XVC769AE101 3BHE006373R0101, which routes signals to CMA136 3DDE300416 analog modules and IMDSO14 digital modules in the AC400 controller rack. The unit’s 2.5 kV isolation prevents noise from nearby motors affecting temperature readings, ensuring reactor stability within ±1°C—critical for urea yield.

In a municipal waste incineration plant, XVC769AE101 3BHE006373R0101 manages signals for emission control systems:

- Connects 16 gas analyzers (4-20 mA) measuring CO, NOx, and O₂ levels

- Terminates 16 digital outputs from the controller to actuate damper motors

Its wide -20°C to +70°C operating range withstands temperature swings in the incinerator’s control room, while diagnostic LEDs simplify troubleshooting of intermittent sensor connections common in harsh environments.

ABB XVC769AE101 3BHE006373R0101

Related model recommendations

- XVC768AE101 3BHE006372R0101: 16-channel variant of XVC769AE101 3BHE006373R0101for smaller systems.

- CMA136 3DDE300416: Analog input module that receives signals routed through XVC769AE101 3BHE006373R0101.

- IMDSO14: Digital output module paired with XVC769AE101 3BHE006373R0101to control field actuators.

- AC400 3BSE008508R1: Advant controller that processes signals terminated by XVC769AE101 3BHE006373R0101.

- TB820V2: Terminal base compatible with XVC769AE101 3BHE006373R0101for expanded wiring options.

- XVC769BE101 3BHE006374R0101: XVC769AE101variant with enhanced surge protection for outdoor installations.

- 1SVR011700R0000: 24 V DC power supply for auxiliary circuits connected via XVC769AE101 3BHE006373R0101.

Installation, commissioning and maintenance instructions

Installation preparation

Mount XVC769AE101 3BHE006373R0101 on a 35 mm DIN rail in a clean, dry cabinet, ensuring ambient temperature stays within -20°C to +70°C. Leave 50 mm clearance above/below for airflow and wiring access. Before wiring, verify the unit’s part number matches the bill of materials to ensure compatibility with connected CMA136 3DDE300416 modules. Use 0.2-2.5 mm² stranded wires with ferrules, inserting into terminals until a click confirms secure seating. Separate analog and digital wiring within the unit to minimize cross-talk, and ground the unit’s chassis to the cabinet ground bar.

Maintenance suggestions

Weekly checks of XVC769AE101 3BHE006373R0101 involve verifying green power LED and checking for red fault LEDs. Monthly, gently tug on wire connections to ensure secure seating—reseat any loose wires. Clean terminals quarterly with compressed air to remove dust. If a channel fails, swap the wire to a spare channel to isolate issues; replace XVC769AE101 3BHE006373R0101 if multiple channels fault, using an ABB-approved spare to maintain isolation ratings. Document all maintenance in a log to track unit performance over time.

Service and guarantee commitment

XVC769AE101 3BHE006373R0101 is backed by a 3-year warranty, covering defects in materials and workmanship. ABB’s technical support team provides 24/7 assistance for wiring design, including guidance on integrating with CMA136 3DDE300416 and IMDSO14 modules.

Customers receive access to detailed wiring diagrams and termination guides specific to XVC769AE101 3BHE006373R0101. ABB offers on-site training for technicians on spring clamp wiring best practices. With global distribution centers, replacement units ship within 48 hours, minimizing downtime in critical control loops. Trust XVC769AE101 3BHE006373R0101 for reliable I/O termination, backed by ABB’s expertise in industrial control infrastructure.