Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | XVC770BE101 3BHE021083R0101 |

| Manufacturer | ABB |

| Product category | High-density I/O termination unit (Advant OCS systems) |

| Number of channels | 32 universal input/output channels |

| Compatible signal types | Analog (4-20 mA, 0-10 V, thermocouples) and digital (24 V DC) signals |

| Terminal type | Spring clamp (accepts 0.5-2.5 mm² wires) |

| Isolation | 3 kV AC (channel-to-bus, channel-to-channel) |

| Operating voltage | 24 V DC ±10% |

| Power consumption | ≤ 5 W |

| Operating temperature | -25°C to +70°C |

| Dimensions (W×H×D) | 140 mm × 180 mm × 90 mm |

| Installation method | DIN rail mounting (35 mm standard rail) with locking clips |

| Diagnostic features | Channel-level fault LEDs, power status indicator, short circuit detection |

| Compliance | IEC 61131-2, CE, UL 508 |

| Compatible systems | ABB Advant Controller 400, DSTA131 digital input module, CMA136 analog modules, MasterPiece 200/1 |

XVC770BE101 3BHE021083R0101

Product introduction

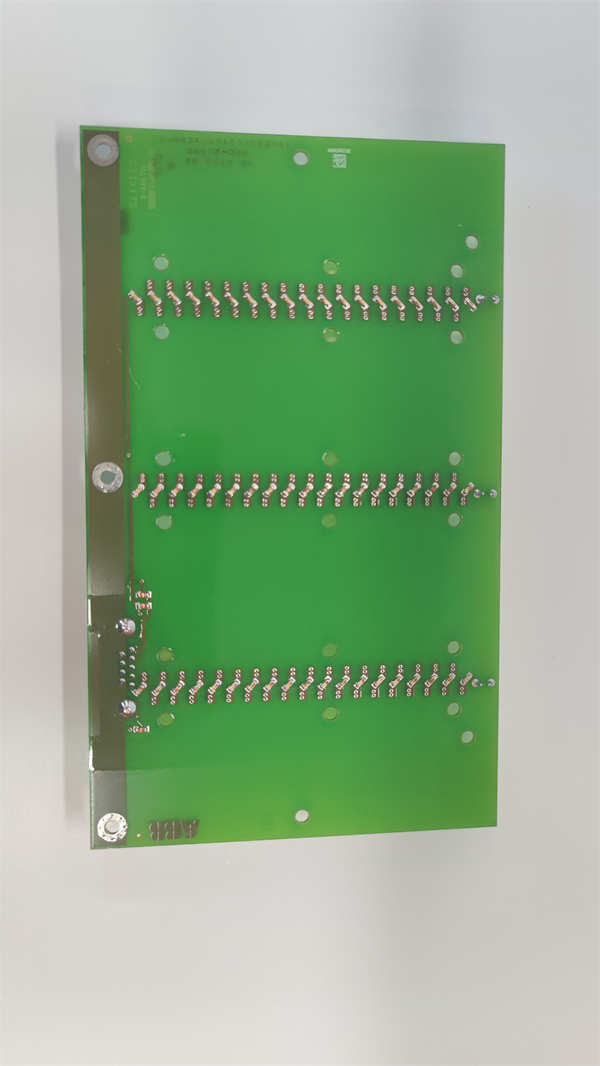

The XVC770BE101 3BHE021083R0101 is a high-density I/O termination unit from ABB, engineered for Advant Open Control System (OCS) architectures to streamline wiring between field devices and control modules. As an advanced successor to earlier XVC series units like the XVC768115 3BHB007211R115, it serves as a critical interface, organizing signal connections and protecting control electronics from field-side electrical noise.

With 32 universal channels supporting both analog and digital signals, XVC770BE101 3BHE021083R0101 eliminates the need for multiple specialized termination units, reducing cabinet space by up to 40% in dense installations. Its spring clamp terminals ensure vibration-resistant connections, while 3 kV isolation enhances reliability in electrically harsh environments—ideal for industries such as chemical processing, power generation, and metallurgy. Whether paired with DSTA131 digital input modules for discrete signal monitoring or analog modules for process variables, XVC770BE101 3BHE021083R0101 delivers organized, robust signal management, simplifying installation and maintenance in complex automation systems.

Core advantages and technical highlights

High channel density

XVC770BE101 3BHE021083R0101’s 32 universal channels accommodate a mix of analog and digital signals in a compact footprint, making it ideal for space-constrained control cabinets. In a gas turbine control system, this density allows termination of:

- 16 digital inputs (solenoid valve statuses)

- 8 analog inputs (temperature/pressure transmitters)

- 8 digital outputs (actuator commands)

All in a single unit, reducing wiring complexity compared to using two XVC768115 3BHB007211R115 units.

Tool-free spring terminals

Unlike screw-clamp designs, the spring terminals of XVC770BE101 3BHE021083R0101 enable tool-free wire insertion and removal, cutting wiring time by 50% during installation or maintenance. In a water treatment plant’s upgrade project, technicians can quickly rewire sensor connections during scheduled shutdowns, minimizing downtime while ensuring secure connections that resist loosening from pump vibrations.

Enhanced diagnostic visibility

Integrated channel-level LEDs indicate signal presence and faults, with a dedicated alarm output for system-level alerts. In a pharmaceutical batch reactor control panel, a flashing red LED on XVC770BE101 3BHE021083R0101 immediately identifies a broken wire to a critical pH sensor, allowing technicians to resolve the issue before it impacts batch quality—improving troubleshooting efficiency over non-indicated termination units.

Typical application scenarios

In a coal-fired power plant’s boiler control system, XVC770BE101 3BHE021083R0101 serves as the central termination hub for boiler auxiliary systems:

- Channels 1-12: 4-20 mA signals from flue gas analyzers and pressure transmitters, routed to analog input modules.

- Channels 13-24: 24 V DC digital inputs from flame detectors and limit switches, connected to DSTA131

- Channels 25-32: Dry contact outputs from safety relays, terminating to valve actuators.

The unit’s 3 kV isolation protects the Advant Controller 400 from electrical noise generated by boiler fans and feed pumps, ensuring stable signal transmission. Its rugged design withstands the plant’s high ambient temperatures (up to 65°C), maintaining reliability in harsh conditions.

In a chemical plant’s batch processing area, XVC770BE101 3BHE021083R0101 integrates with legacy and modern systems:

- Terminates signals from legacy thermocouples (analog) and new smart pressure sensors (digital).

- Links to both MasterPiece 200/1 controllers and newer HMI systems via its modular backplane.

- Supports partial system upgrades, as its universal channels accommodate mixed signal types during transition periods.

This flexibility allows the plant to modernize incrementally without replacing the entire termination infrastructure.

XVC770BE101 3BHE021083R0101

Related model recommendations

- XVC768115 3BHB007211R115: 16-channel predecessor to XVC770BE101 3BHE021083R0101, used in smaller systems.

- DSTA131: Digital input module that connects to field devices via XVC770BE101 3BHE021083R0101’s terminals.

- CMA136 3DDE300416: Analog input module paired with XVC770BE101 3BHE021083R0101for process variable monitoring.

- AC400: Advant Controller that processes signals routed through XVC770BE101 3BHE021083R0101.

- 1SVR011700R0000: 24 V DC power supply for energizing XVC770BE101 3BHE021083R0101and connected field devices.

- XVC771BE101: Redundant variant of XVC770BE101 3BHE021083R0101for high-availability systems.

- TB820V2: Terminal base adapter for integrating XVC770BE101 3BHE021083R0101with S800 I/O modules.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing XVC770BE101 3BHE021083R0101, ensure the control cabinet is de-energized and grounded. Mount the unit on a 35 mm DIN rail, leaving 50 mm clearance above/below for airflow and wiring access. Use 0.5-2.5 mm² stranded wires with ferrules for spring terminal connections; strip 8 mm of insulation and insert wires into terminal ports until they lock into place (verify with a gentle tug). Connect the backplane ribbon cable to the adjacent control module, ensuring proper alignment with the connector pins. Power the unit via 24 V DC, verifying the green power LED illuminates—avoid reverse polarity, which may damage the terminal block.

Maintenance suggestions

Inspect XVC770BE101 3BHE021083R0101 monthly by checking for illuminated channel LEDs (indicating active signals) and absence of fault LEDs. Clean dust from terminals quarterly using compressed air (max 5 bar) to prevent signal interference. Test spring terminal retention annually by gently pulling wires—replace the unit if any wire loosens. If a channel fails, swap the signal to a spare channel to isolate issues; replace XVC770BE101 3BHE021083R0101 with an ABB-approved spare if internal terminal faults are confirmed, ensuring the replacement is wired identically to maintain system integrity.

Service and guarantee commitment

XVC770BE101 3BHE021083R0101 is backed by a 3-year warranty, covering defects in materials and workmanship under normal operating conditions. ABB’s legacy systems support team provides technical guidance for integration with Advant OCS components, including pairing with DSTA131 modules and legacy controllers.

Customers receive access to detailed wiring diagrams and terminal assignment guides for XVC770BE101 3BHE021083R0101. ABB offers on-site installation support for complex systems, ensuring proper grounding and signal routing. With global distribution centers, replacement units are available within 48 hours for critical applications, minimizing unplanned downtime. Trust XVC770BE101 3BHE021083R0101 to deliver reliable signal termination, backed by ABB’s commitment to supporting both legacy and transitional automation systems.