Description

XXD129A01: Product Overview

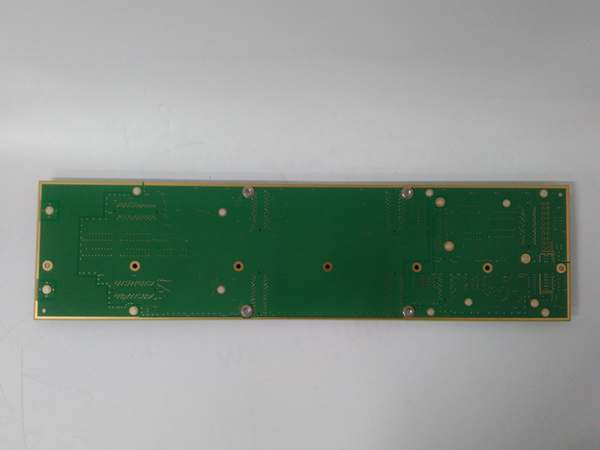

The ABB XXD129A01 is a compact, high-performance industrial control card module designed to deliver reliable control and monitoring for a wide range of industrial automation applications. As part of ABB’s portfolio of industrial control solutions, it combines programmable logic, flexible communication interfaces, and a space-saving design to meet the demands of modern manufacturing and process control systems.

Role in Automation Systems:

The XXD129A01 serves as a core component in distributed control systems (DCS) or programmable logic controllers (PLC) setups, enabling real-time monitoring and adjustment of industrial processes. Its modular design allows it to integrate seamlessly with other ABB control devices (e.g., motor controllers, sensors) and third-party equipment, forming a cohesive automation ecosystem.

Core Functionality:

-

Programmability: Users can customize the module’s logic via software to adapt to specific application requirements, such as sequential control, PID调节, or alarm handling.

-

Communication Capability: Equipped with multiple communication interfaces (e.g., Modbus RTU/TCP, Profinet), the module enables data exchange with上位机 (host computers), SCADA systems, or other field devices, facilitating remote monitoring and control.

-

Compact Design: The cassette-style form factor minimizes space requirements, making it ideal for installations where panel space is limited.

Platform Benefits:

-

Flexibility: Supports a wide range of input/output (I/O) configurations, allowing adaptation to diverse industrial signals (digital, analog).

-

Reliability: Built with industrial-grade components, the module withstands harsh environmental conditions (e.g., temperature fluctuations, humidity) and ensures long-term stable operation.

-

Scalability: Can be expanded with additional modules (e.g., I/O expansion boards) to accommodate growing system requirements.

ABB XXD129A01

Technical Specifications

|

Parameter

|

Value

|

|---|---|

|

Model Number

|

XXD129A01

|

|

Manufacturer

|

ABB

|

|

Product Type

|

Industrial Control Card Module

|

|

Operating Voltage

|

220V AC/DC

|

|

Operating Temperature

|

-40°C ~ +70°C

|

|

Working Humidity

|

≤95%

|

|

Protection Level

|

IP20

|

|

Communication Protocols

|

Modbus, Profinet, EtherNet/IP

|

|

Mounting Style

|

Cassette (panel-mounted)

|

|

Certifications

|

CE, UL (inferred from ABB’s standards)

|

Core Features & Customer Value

1. Flexible Programming:

The XXD129A01’s programmable logic allows users to tailor its functionality to specific applications, reducing the need for custom hardware and lowering development costs. For example, in a packaging line, the module can be programmed to trigger a conveyor belt based on sensor inputs, optimizing workflow efficiency.

2. Seamless Communication:

With support for industry-standard protocols (Modbus, Profinet), the module integrates easily with existing automation systems. This enables real-time data sharing between the XXD129A01 and上位机 systems, allowing operators to monitor process variables (e.g., temperature, pressure) remotely and make informed decisions.

3. Space-Saving Design:

The compact cassette form factor minimizes the footprint in control panels, making it ideal for facilities with limited space. This design also simplifies installation and maintenance, as the module can be easily replaced or upgraded without disrupting the entire system.

4. High Reliability:

Built to withstand harsh industrial environments, the XXD129A01 uses industrial-grade components that resist vibration, temperature changes, and humidity. This reliability reduces downtime and maintenance costs, ensuring continuous operation of critical processes.

ABB XXD129A01

Typical Applications

The ABB XXD129A01 is suitable for a variety of industrial automation scenarios, including:

-

Manufacturing Lines:

-

Controls robotic arms, conveyor belts, and assembly equipment in automotive or electronics manufacturing.

-

Example: In a car assembly plant, the module adjusts the speed of a conveyor belt based on the position of a robotic arm, ensuring precise part placement.

-

-

Process Control:

-

Monitors and regulates temperature, pressure, and flow in chemical or pharmaceutical processes.

-

Example: In a chemical reactor, the module maintains a constant temperature by adjusting the flow of cooling water, preventing overheating and ensuring product quality.

-

-

Material Handling:

-

Manages the movement of materials in warehouses or distribution centers using automated guided vehicles (AGVs) or cranes.

-

Example: In a warehouse, the module directs an AGV to pick up a pallet from a specified location and deliver it to a loading dock, optimizing logistics efficiency.

-