Description

Detailed parameter table

| Parameter Name | Parameter Value |

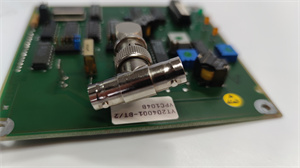

| Product model | YPC104B YT204001-BT |

| Manufacturer | ABB |

| Product category | Positioner control board (for ABB valve positioners) |

| Compatible positioners | ABB V18345, V18346 series intelligent valve positioners |

| Input signal | 4-20 mA (control signal) |

| Output signal | PWM (pulse width modulation) for actuator control |

| Communication | HART protocol (for configuration and diagnostics) |

| Operating voltage | 24 V DC ±15% |

| Power consumption | ≤ 5 W |

| Operating temperature | -40°C to +70°C |

| Dimensions (W×H×D) | 65 mm × 85 mm × 30 mm |

| Mounting method | Internal mounting in valve positioner housing |

| Protection rating | IP65 (when installed in positioner housing) |

| Diagnostic features | Valve travel feedback, actuator current monitoring, fault code storage |

| Calibration method | Automatic (via ABB Valvue software) |

| Certification | CE, ATEX Zone 1/2, IECEx, UL 1604 |

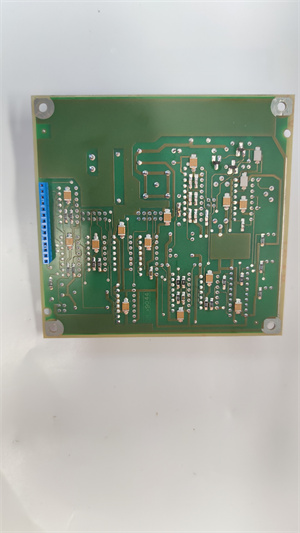

| Material | Epoxy-coated PCB (resistant to moisture and chemical exposure) |

ABB YPC104B YT204001-BT

Product introduction

The YPC104B YT204001-BT is a precision control board from ABB, designed as the core component of V18345 and V18346 series intelligent valve positioners. It serves as the processing and control center, converting 4-20 mA control signals from DCS or PLC systems into precise valve positioning commands. By integrating HART communication, it enables remote configuration, calibration, and diagnostics—critical for optimizing valve performance in industrial processes.

This control board combines advanced signal processing with robust construction, ensuring accurate valve control even in harsh environments with extreme temperatures, vibration, or chemical exposure. The YPC104B YT204001-BT continuously monitors valve travel and actuator performance, providing real-time feedback to the control system and alerting operators to potential issues before they affect process stability. Its compatibility with ABB’s valve positioners makes it an essential component in flow control applications across oil and gas, chemical processing, and power generation industries.

Core advantages and technical highlights

Precision positioning control

The YPC104B YT204001-BT utilizes PWM output technology to achieve valve positioning accuracy within ±0.5% of full scale. In a refinery’s distillation column, this precision ensures flow rates are maintained within tight tolerances (e.g., ±2% of setpoint), optimizing separation efficiency and reducing product waste. The board’s advanced algorithms compensate for valve hysteresis and friction, ensuring consistent response to control signals regardless of wear.

HART-enabled intelligence

Integrated HART communication allows the YPC104B YT204001-BT to transmit diagnostic data alongside the 4-20 mA control signal. In a chemical plant, this enables operators to:

Check valve position remotely without manual inspection

Monitor actuator current to detect binding or wear

Receive alerts for calibration drift or component degradation

This capability reduces maintenance costs by 30% compared to non-communicating positioners, as issues are identified before causing process upsets.

Extreme environment durability

Encased in an epoxy-coated PCB and protected by the positioner’s IP65 housing, the YPC104B YT204001-BT operates reliably in -40°C to +70°C temperatures. In an offshore oil platform’s wellhead control system, it withstands salt spray, vibration, and temperature swings, ensuring choke valves maintain precise flow control—critical for preventing pressure surges in production lines.

ABB YPC104B YT204001-BT

Typical application scenarios

In a natural gas processing plant’s amine sweetening unit, the YPC104B YT204001-BT controls the flow of amine solution through absorption towers. It receives 4-20 mA signals from the DCS (proportional to gas flow rate) and adjusts the control valve position to maintain optimal amine-to-gas ratios. HART communication allows technicians to remotely verify valve travel (0-100%) and check for signs of diaphragm wear via actuator current trends.

In a coal-fired power plant’s boiler feedwater system, the YPC104B YT204001-BT ensures precise control of feedwater flow to match steam demand. Its automatic calibration feature compensates for valve stem wear over time, maintaining positioning accuracy within ±0.5%. During startups, the board’s diagnostic functions verify valve operation, detecting issues like sticking stems that could lead to boiler water level instability—preventing costly shutdowns.

Related model recommendations

YPC105A YT204002-BT: Advanced variant of YPC104B YT204001-BT with FOUNDATION Fieldbus communication.

V18345-1010: ABB valve positioner model that integrates YPC104B YT204001-BT for linear valves.

V18346-1010: Rotary valve positioner using YPC104B YT204001-BT for quarter-turn valves.

YT2500: ABB Valvue software for configuring and calibrating YPC104B YT204001-BT via HART.

HART Modem 3070: Interface device for connecting a PC to YPC104B YT204001-BT during setup.

YTC102: Manual calibration tool compatible with YPC104B YT204001-BT for field adjustments.

YPC104C YT204001-CT: Replacement board for YPC104B YT204001-BT with enhanced temperature tolerance.

Installation, commissioning and maintenance instructions

Installation preparation: Ensure the valve positioner housing is clean and dry before mounting YPC104B YT204001-BT. Use the provided screws to secure the board to the internal mounting points, verifying all connectors align with the positioner’s wiring harness. Connect the 4-20 mA signal wire (twisted-pair, shielded) and 24 V DC power, ensuring correct polarity. For hazardous areas, confirm the positioner housing is properly sealed to maintain ATEX/IECEX certification.

Maintenance suggestions: Inspect the YPC104B YT204001-BT annually during scheduled shutdowns by checking for corrosion or loose connections. Use ABB Valvue software to run diagnostic tests, verifying valve travel accuracy and actuator response. Calibrate every 12-18 months (or after maintenance) via the automatic calibration function to maintain positioning precision. If fault codes persist after troubleshooting, replace the board with an ABB-approved unit, transferring configuration data via HART to minimize downtime.

Service and guarantee commitment

The YPC104B YT204001-BT is backed by a 2-year warranty, covering defects in materials and workmanship under normal operating conditions. ABB’s valve automation technical support team provides specialized assistance for configuration, calibration, and troubleshooting, including access to HART protocol guides and diagnostic flowcharts.

Customers receive access to training resources for YPC104B YT204001-BT maintenance, ensuring technicians can perform calibration and repairs efficiently. ABB maintains a global inventory of replacement boards to minimize downtime in critical applications. Our commitment to quality ensures the board delivers reliable valve control, with technical experts available to support customers throughout the product lifecycle.