Description

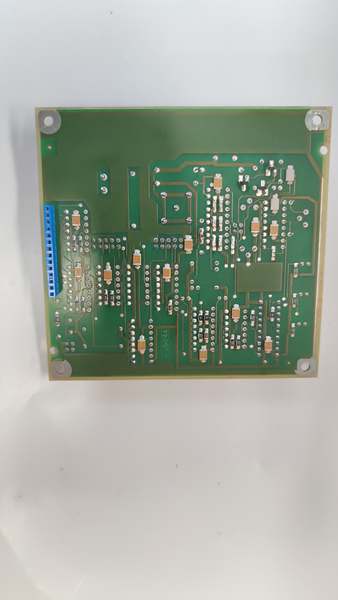

ABB YPC104B YT204001-BT

YPC104B YT204001-BT: Product Overview

The ABB YPC104B YT204001-BT is an industrial-grade modem board designed to facilitate robust serial communication in process automation systems. As a critical component of ABB’s industrial communication portfolio, it enables seamless data exchange between ABB controllers (e.g., AC 800PEC), field devices (e.g., sensors, actuators), and engineering workstations—even in harsh industrial environments.

Role in Automation Systems:

Positioned as a “communication bridge,” the YPC104B YT204001-BT connects legacy serial devices (e.g., PLCs, RTUs) to modern control networks, ensuring interoperability and extending the lifespan of existing infrastructure. It is widely used in industries like oil and gas, water treatment, and manufacturing, where reliable data transmission is essential for process stability and efficiency.

Core Functionality:

-

Serial Communication: Supports RS-232 and RS-485 interfaces, allowing connection to a wide range of field devices and controllers.

-

Protocol Conversion: Compatible with Modbus RTU, a standard industrial protocol, enabling seamless integration with third-party systems.

-

Robust Design: Built with industrial-grade components to withstand vibration, temperature fluctuations, and electromagnetic interference (EMI)—common in industrial settings.

Platform Benefits (ABB Automation Ecosystem):

The YPC104B YT204001-BT leverages ABB’s reputation for reliability and scalability. Key benefits include:

-

Seamless Integration: Compatible with ABB’s AC 800PEC and System 800xA platforms, reducing setup time and effort.

-

Scalability: Supports expansion via additional communication modules, adapting to growing operational needs.

-

Diagnostic Capabilities: Built-in status LEDs and fault logging simplify troubleshooting, reducing mean time to repair (MTTR).

Technical Specifications

Model Number: YPC104B YT204001-BT

Manufacturer: ABB

Product Type: Industrial Modem Board

-

Communication Interfaces: 1 × RS-232, 1 × RS-485

-

Protocol Support: Modbus RTU

-

Operating Temperature: -20°C to +60°C (-4°F to 140°F)

-

Storage Temperature: -40°C to +85°C (-40°F to 185°F)

-

Humidity: 5% to 95% non-condensing

-

Dimensions (W×H×D): 110 mm × 115 mm × 22 mm (4.33 in × 4.53 in × 0.87 in)

-

Weight: 0.1 kg (0.22 lbs)

-

Power Supply: 24 V DC (±10%)

-

Certifications: CE, UL (inferred from ABB’s industrial product standards)

ABB YPC104B YT204001-BT

Core Features & Customer Value

1. Reliable Serial Communication:

The YPC104B YT204001-BT’s support for RS-232 and RS-485 interfaces ensures compatibility with a wide range of field devices, from legacy PLCs to modern sensors. This flexibility reduces the need for protocol converters, saving time and money during system integration.

2. Modbus RTU Protocol Support:

By supporting Modbus RTU, the module enables seamless communication with third-party devices (e.g., Siemens PLCs, Schneider sensors). This interoperability is critical for customers with mixed-vendor systems, ensuring that all devices can share data reliably.

3. Robust Design for Harsh Environments:

Industrial-grade components and a wide operating temperature range (-20°C to +60°C) ensure that the module withstands vibration, temperature fluctuations, and EMI—common in industrial settings. This reliability reduces downtime and maintenance costs, which is essential for mission-critical applications like power generation or chemical processing.

4. Compact and Easy to Install:

The module’s compact dimensions (110 mm × 115 mm × 22 mm) make it easy to install in control cabinets, even in space-constrained environments. This is particularly valuable for customers upgrading existing systems, as it eliminates the need for larger control cabinets.

Typical Applications

The ABB YPC104B YT204001-BT is widely used in industries requiring reliable serial communication:

-

Oil and Gas:

-

Connects remote sensors (e.g., pressure, temperature) to central controllers, enabling real-time monitoring of pipeline operations.

-

Example: In an offshore oil rig, the module transmits data from a pressure sensor to the central controller, allowing operators to adjust valve positions and maintain optimal flow rates.

-

-

Water Treatment:

-

Interfaces with pump controllers and valve actuators, enabling precise control of water distribution systems.

-

Example: A municipal water treatment plant uses the module to connect a pump controller to the central SCADA system, ensuring that water levels in tanks are maintained within optimal ranges.

-

-

Manufacturing:

-

Connects robotic arms and conveyor systems to PLCs, enabling synchronized operation and real-time monitoring.

-

Example: In an automotive assembly line, the module transmits data from a robotic arm to the PLC, allowing operators to adjust the arm’s position and ensure precise part placement.

-