Description

YYT107A: Product Overview

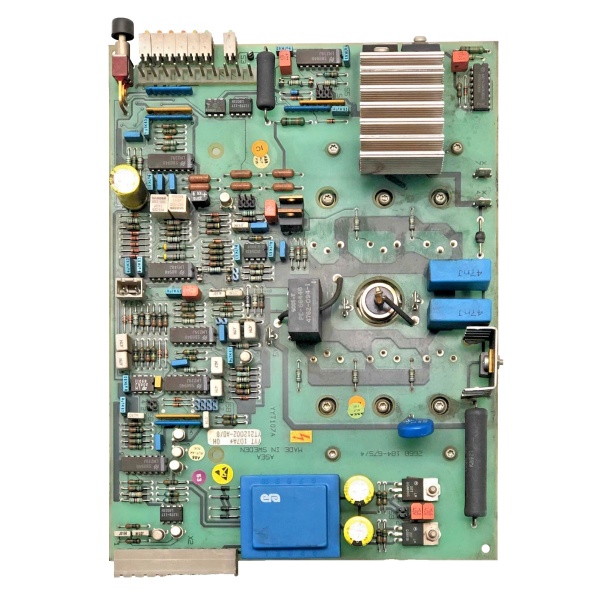

The ABB YYT107A is a critical power supply component designed specifically for ABB industrial robot systems. As a rectifier module, its primary role is to convert incoming AC power (typically 380–480 VAC) into the DC power required by robot controllers, servo drives, and end-effectors. This conversion is essential for maintaining the precision and reliability of robotic operations in industries such as automotive manufacturing, aerospace, and consumer goods.

Role in Automation Systems:

In ABB’s robotic automation ecosystem, the YYT107A acts as the “power backbone” for robot cells. It ensures that all downstream components (e.g., robot arms, welding guns, painting nozzles) receive consistent DC power, which is vital for:

-

Precision Motion Control: Stable power prevents voltage fluctuations that could disrupt servo motor performance, ensuring accurate positioning and repeatability.

-

Process Consistency: For welding or painting robots, steady power supply maintains consistent arc stability or paint flow, reducing defects and rework.

-

System Reliability: The module’s built-in protection features (overload, short-circuit) safeguard expensive robot components from power surges or faults.

Core Functionality:

-

AC/DC Conversion: Utilizes advanced switch-mode technology to efficiently convert AC to DC, minimizing energy loss and heat generation.

-

Voltage Regulation: Maintains a constant output voltage despite variations in input AC voltage, ensuring compatibility with robot system requirements.

-

Protection Mechanisms: Includes overcurrent protection, overvoltage protection, and thermal shutdown to prevent damage from abnormal operating conditions.

Platform Benefits (ABB Robot Systems):

The YYT107A is optimized for seamless integration with ABB’s robot controllers (e.g., IRC5, Omnicore) and servo drives. Its compact design allows for easy installation in robot control cabinets, while its high efficiency (≥90%) reduces energy consumption and operational costs. Additionally, the module’s compatibility with ABB’s diagnostic tools enables predictive maintenance, minimizing downtime.

ABB YYT107A

Technical Specifications

Model Number: YYT107A

Manufacturer: ABB

Product Type: Industrial Rectifier Module

-

Input Voltage: 380–480 VAC (3-phase)

-

Output Voltage: 24–48 VDC (adjustable, depending on robot model)

-

Output Current: Up to 50 A (continuous)

-

Efficiency: ≥90% (typical)

-

Protection Features: Overload protection, short-circuit protection, thermal shutdown

-

Operating Temperature: 0°C to +50°C (32°F to 122°F)

-

Cooling: Forced air cooling (integrated fan)

-

Dimensions (W×H×D): 300 mm × 150 mm × 100 mm (approximate)

-

Weight: 5 kg (approximate)

-

Certifications: CE, UL, RoHS

Core Features & Customer Value

1. High Efficiency for Energy Savings:

The YYT107A’s switch-mode design achieves efficiencies of ≥90%, which is significantly higher than traditional linear power supplies. For customers, this translates to lower electricity bills and reduced heat dissipation in control cabinets—critical for maintaining optimal operating conditions in industrial environments.

2. Stable Power for Precision Operations:

By providing regulated DC power, the module ensures that robot servo motors and actuators perform with high precision. This is particularly valuable in applications like welding, where even minor voltage fluctuations can lead to defective welds and increased scrap rates.

3. Robust Protection for Reduced Downtime:

The YYT107A’s built-in protection features safeguard robot systems from power-related faults. For example, if a short circuit occurs in a downstream component, the module’s short-circuit protection will trip instantly, preventing damage to the robot controller or servo drives. This reduces downtime and maintenance costs, ensuring continuous production.

4. Seamless Integration with ABB Robots:

Designed specifically for ABB robot systems, the YYT107A integrates seamlessly with ABB’s controller software (e.g., RobotStudio) and diagnostic tools. This allows engineers to monitor the module’s status (e.g., output voltage, temperature) in real time, enabling proactive maintenance and minimizing unexpected failures.

ABB YYT107A

Typical Applications

The ABB YYT107A is widely used in ABB robot-based automation systems across various industries:

-

Automotive Manufacturing:

-

Powers welding robots (e.g., ABB IRB 6700) in car body assembly lines. The stable DC power ensures consistent arc stability, reducing weld defects and improving production efficiency.

-

Example: In a automotive plant, the YYT107A supplies power to 10 welding robots, maintaining a 98% first-pass yield rate.

-

-

Painting and Coating:

-

Provides power to painting robots (e.g., ABB IRB 5500) in furniture or appliance manufacturing. Steady power supply ensures uniform paint application, minimizing overspray and material waste.

-

Example: A furniture manufacturer uses the YYT107A to power 5 painting robots, reducing paint consumption by 15% compared to unregulated power supplies.

-

-

Material Handling:

-

Supports material handling robots (e.g., ABB IRB 120) in warehouses or distribution centers. Reliable power ensures smooth operation of conveyor belts and grippers, preventing delays in logistics.

-

Example: In a warehouse, the YYT107A powers 8 material handling robots, increasing throughput by 20% due to reduced downtime.

-