Description

Detailed parameter table

| Parameter name | Parameter value |

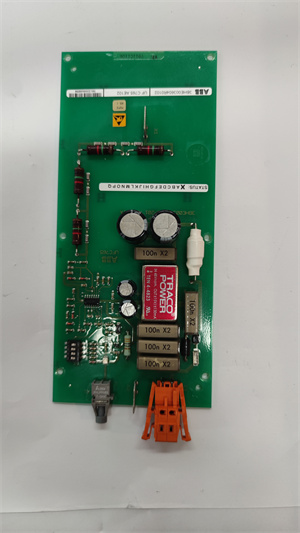

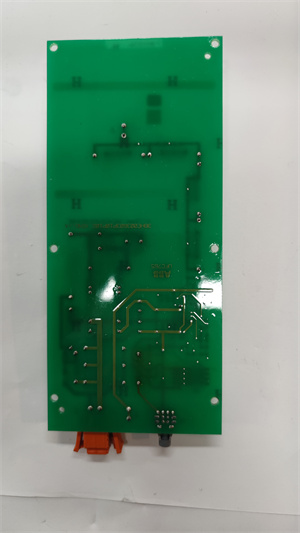

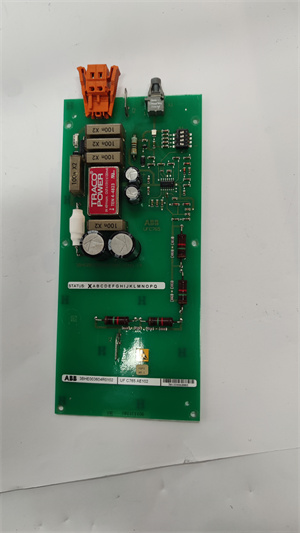

| Product model | 3BHE003604R0102 UFC765AE102 |

| Manufacturer | ABB |

| Product category | Earth Fault Monitor Board (also recognized as a Fault – Locating Indicator (FLI) board in some applications, with diverse functions across different industrial setups) |

| Operating voltage range | 120 V to 480 V AC (suitable for a wide variety of industrial power systems, from low – voltage distribution networks in small – scale manufacturing units to medium – voltage systems in larger industrial complexes) |

| Power supply | 24 VDC (in applications where it functions as a Fault – Locating Indicator (FLI) board, like in electric arc furnace (EAF) setups, providing stable and efficient power for its operations) |

| Power consumption | 5 W (low – power consumption, ensuring energy – efficient operation and reduced strain on the overall power infrastructure) |

| Operating temperature | – 5 °C to + 40 °C (designed to function reliably in typical indoor industrial environments, where temperature variations are generally within this range. However, in some sources, it has an extended operating temperature range of – 20 °C to + 80 °C, making it adaptable to more challenging environments, such as outdoor – exposed electrical enclosures in certain industrial settings) |

| Storage temperature range | – 40 °C to + 85 °C (allows for safe storage of the board in extreme temperature conditions before installation, ensuring its integrity is maintained over time) |

| Protection class | IP20 (offers basic protection against solid objects larger than 12 mm, such as fingers, and is suitable for indoor use in relatively clean environments. However, some sources suggest it might have a more robust protection like IP65 in certain variants or applications, which provides protection against dust and water jets, enabling operation in harsher, dust – filled, or wet industrial environments) |

| Dimensions (LxWxH) | 173 mm x 104 mm x 42 mm (compact size facilitates easy installation within control cabinets and electrical enclosures, optimizing space utilization. In other descriptions, dimensions are given as 45.3 cm x 12.8 cm x 4.8 cm, which might be for a different version or due to measurement discrepancies in different sources, but both sizes are designed with installation in mind) |

| Weight | 0.5 kg (lightweight construction makes it easy to handle during installation and maintenance. Another source indicates a weight of 1.18 kg, which could be due to differences in components or packaging details, but overall, it remains manageable for field operations) |

| Communication interface | Modbus RTU (enables seamless integration with other industrial devices and control systems, allowing for real – time data exchange. In applications related to the masterbus 300 communication network, it supports masterbus 300 communication protocol, facilitating communication within specific industrial communication setups) |

| Relay outputs | 2 (these relay outputs can be used to trigger alarms or initiate protective actions when an earth fault or other relevant faults are detected, enhancing the overall safety and control of the industrial system) |

| Input type | Voltage (designed to receive voltage – based signals for monitoring and fault – detection purposes) |

| Number of channels | 3 (in applications like electric arc furnace secondary circuit monitoring, these channels can be used to monitor different phases or electrical parameters related to fault detection) |

| Input current range | 0 to 10 A (when monitoring electrical currents in relevant circuits, it can handle currents within this range for accurate fault detection) |

| Output voltage range | 0 to 5 V (provides output signals within this voltage range, which can be used to control other devices or provide feedback to the control system based on the detected fault conditions) |

| Hot – swappable | Yes (in applications related to the masterbus 300 network, the ability to be hot – swappable allows for replacement of the board without shutting down the entire system, minimizing downtime and ensuring continuous operation) |

| Fault types detected | Earth faults, open circuits, short circuits (capable of identifying various types of electrical faults, which is crucial for maintaining the integrity and safety of industrial electrical systems. In different applications, such as in EAF secondary circuits, it can also detect phase – to – phase faults) |

| Fault location | Can identify the specific device causing the fault (in masterbus 300 network applications, this feature helps in quickly pinpointing the source of the problem, enabling efficient troubleshooting and repair. In EAF applications, it can locate faults within the secondary circuit) |

| Conformal coated | Yes (for harsh environments, the conformal coating protects the board’s components from moisture, dust, and chemical contaminants, ensuring reliable operation in challenging industrial settings) |

ABB 3BHE003604R0102 UFC765AE102

Product introduction

The ABB 3BHE003604R0102 UFC765AE102 is a highly versatile and advanced board designed to meet the critical monitoring and protection needs of industrial electrical systems. With its multifaceted capabilities, it plays a pivotal role in ensuring the continuous and safe operation of various industrial processes.

Functioning primarily as an Earth Fault Monitor Board, it is engineered to detect earth faults with high precision. Earth faults can pose significant risks to industrial systems, leading to equipment damage, power outages, and safety hazards. By constantly monitoring the electrical system for any abnormal current flow to the ground, the 3BHE003604R0102 UFC765AE102 can quickly identify and alert operators to potential earth – fault situations. This enables timely intervention, preventing major disruptions to the industrial process.

In addition to earth – fault monitoring, it also serves as a Fault – Locating Indicator (FLI) board in specific applications, such as in electric arc furnace (EAF) setups. In EAFs, which are used extensively in the steel – making and metal – processing industries, electrical faults can occur frequently due to the high – current and high – temperature operating conditions. The 3BHE003604R0102 UFC765AE102 can detect and locate faults in the EAF secondary circuit, including grounding faults, phase – to – phase faults, and open circuits. It can also monitor the overall condition of the EAF secondary circuit and provide early – warning alarms for potential faults. This helps in optimizing the performance of the EAF, reducing downtime, and extending the lifespan of the equipment.

The board is also utilized in communication network applications, particularly in the masterbus 300 communication network. Here, it can identify and locate faults such as open circuits, short circuits, and ground faults. It has the ability to pinpoint the specific device that is causing the fault within the network. This is invaluable for maintaining the integrity of the communication network, as any fault in the network can disrupt the seamless transfer of data between different components of the industrial control system.

Core advantages and technical highlights

Wide operating voltage range: With an operating voltage range spanning from 120 V to 480 V AC, the 3BHE003604R0102 UFC765AE102 can be easily integrated into a diverse range of industrial power systems. Whether it’s a small – scale manufacturing unit with a relatively low – voltage distribution network or a large – scale industrial complex with a medium – voltage system, this board can adapt and function effectively. This versatility eliminates the need for custom – designed voltage – specific boards for different applications, reducing costs and simplifying the procurement process.

Robust temperature tolerance: The board can operate in temperatures ranging from – 5 °C to + 40 °C as per some specifications, and in an extended range of – 20 °C to + 80 °C in other descriptions. This wide temperature tolerance makes it suitable for use in various industrial environments. In cold storage facilities, where temperatures can drop well below freezing, or in hot industrial plants, such as steel mills or foundries, where temperatures can soar, the 3BHE003604R0102 UFC765AE102 can continue to function reliably. This ensures continuous monitoring and protection of the electrical systems, regardless of the ambient temperature conditions.

Efficient communication capabilities: Equipped with a Modbus RTU communication interface, it can seamlessly integrate with existing industrial control systems. This allows for real – time data exchange between the board and other devices in the system. For example, it can send fault – detection data to a central control unit, which can then analyze the data and take appropriate action. In a large – scale industrial plant with multiple electrical systems and control devices, this real – time communication ensures that any faults are detected and addressed promptly, minimizing the impact on production. In applications related to the masterbus 300 network, its support for the masterbus 300 communication protocol further enhances its communication capabilities within specific industrial communication setups.

Hot – swappable feature: In applications related to the masterbus 300 network, the hot – swappable feature of the 3BHE003604R0102 UFC765AE102 is a significant advantage. This means that the board can be replaced without shutting down the entire system. In industrial operations where continuous uptime is crucial, such as in power generation plants or 24/7 manufacturing facilities, the ability to replace a faulty board without system shutdowns reduces downtime to a minimum. This not only saves time but also prevents potential production losses and revenue impacts.

Conformal coating for harsh environments: The conformal coating on the board protects its components from moisture, dust, and chemical contaminants. In industrial environments where there is a high presence of dust, such as in mining operations or cement plants, or in areas with high humidity or chemical exposure, like in chemical processing plants, this conformal coating ensures the long – term reliability of the board. It prevents the corrosion of components, which could otherwise lead to malfunctions and failures, thus extending the lifespan of the board and reducing maintenance costs.

Typical application scenarios

Steel and metal – processing industry: In steel – making plants that use electric arc furnaces, the 3BHE003604R0102 UFC765AE102 is an essential component. It monitors the EAF secondary circuit for faults. For instance, if there is a phase – to – phase fault in the EAF, which can occur due to arcing between electrodes or damaged conductors, the board can quickly detect the fault. It then sends an alarm signal to the control room, and the relay outputs can be used to trigger protective devices, such as circuit breakers, to isolate the faulty section. This prevents damage to the expensive EAF equipment and ensures the safety of the operators.

Power generation and distribution: In power generation plants, whether they are fossil – fuel – based, hydro – electric, or renewable energy plants, the board can be used to monitor the electrical distribution systems for earth faults. For example, in a wind farm, where there are numerous wind turbines and a complex electrical distribution network, an earth fault in one of the turbines’ electrical systems can be detected by the 3BHE003604R0102 UFC765AE102. The board can communicate the fault location to the maintenance team, allowing them to quickly identify and rectify the problem. This helps in maintaining the stable operation of the power generation plant and ensuring a continuous supply of electricity to the grid.

Industrial automation and control systems: In large – scale manufacturing plants with complex industrial automation systems, the board can be integrated into the control network. It can monitor the communication lines within the network for faults. If there is an open circuit or a short circuit in the communication cables that connect different sensors, actuators, and control units, the 3BHE003604R0102 UFC765AE102 can detect the fault and identify the location. This ensures that the control system can continue to function smoothly, as any disruption in communication can lead to incorrect control actions and production inefficiencies.

Related model recommendations

UBC717BE101 3BHE021887R0101: This digital input/output module from ABB can work in tandem with the 3BHE003604R0102 UFC765AE102 in industrial control systems. For example, the 3BHE003604R0102 can send fault – related signals to the UBC717BE101, which can then use these signals to control the operation of actuators or relays in the system. In a manufacturing plant, if the 3BHE003604R0102 detects an earth fault in a particular area, it can send a signal to the UBC717BE101, which can then turn off the power to that area to prevent further damage.

AI04 analog input module: The AI04 can be used in combination with the 3BHE003604R0102 in applications where both analog and digital data need to be monitored. In a chemical plant, the 3BHE003604R0102 can monitor the electrical system for faults, while the AI04 can measure analog parameters such as temperature, pressure, and flow rate of chemical processes. The data from both modules can be integrated and analyzed in a central control system to ensure the safe and efficient operation of the plant.

ACS2000 Series Boards (related models): In applications related to electric arc furnaces, other boards from the ACS2000 series can complement the 3BHE003604R0102 UFC765AE102. These boards can work together to control and monitor different aspects of the EAF operation. For example, one board can be responsible for controlling the power supply to the EAF, while the 3BHE003604R0102 can focus on fault detection in the secondary circuit. This integration of different boards from the ACS2000 series can optimize the performance of the EAF and improve the overall efficiency of the steel – making process.

ABB 3BHE003604R0102 UFC765AE102

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the ABB 3BHE003604R0102 UFC765AE102, ensure that the installation area is clean and dry. Check the ambient temperature to ensure it is within the operating range of – 5 °C to + 40 °C (or – 20 °C to + 80 °C depending on the source). Use appropriate tools to handle the board, taking care to avoid electrostatic discharge, as the sensitive electronic components can be easily damaged by static electricity. Verify that the power supply connections are correct and that the voltage matches the board’s requirements. If installing in a control cabinet, ensure that there is enough space for the board, considering its dimensions of 173 mm x 104 mm x 42 mm (or 45.3 cm x 12.8 cm x 4.8 cm). Label all the wires that will be connected to the board to avoid misconnection during commissioning.

Maintenance suggestions: Regularly inspect the board for any signs of physical damage, such as cracks or burnt components. Check the connections for looseness or corrosion, especially in environments with high humidity or chemical exposure. Although the board is designed to be reliable, it’s a good practice to periodically test its functionality using appropriate test equipment. In case of any abnormal behavior, first check the wiring and connections before suspecting a problem with the board itself. If a component replacement is needed, always use genuine ABB spare parts to ensure compatibility and maintain the board’s performance. Store spare boards in an anti – static bag in a dry environment to prevent degradation.

Commissioning steps: After installation, power up the system gradually and monitor the operation of the 3BHE003604R0102 UFC765AE102 using appropriate monitoring equipment. Verify that it is communicating correctly with other devices in the system, whether it’s through the Modbus RTU interface or the masterbus 300 communication protocol. Check the relay outputs to ensure they are functioning as expected. If the board has any configuration options, such as input/output settings or fault – detection sensitivity, double – check that they are correctly configured according to the application requirements. Test the board’s ability to detect different types of faults by simulating fault conditions (if possible) to ensure that it is functioning as designed.

Service and guarantee commitment

ABB offers a 1 – year warranty for the 3BHE003604R0102 UFC765AE102, covering any defects in materials or workmanship. This warranty reflects ABB’s confidence in the product’s reliability and durability. In case of any product – related issues, ABB’s global technical support team is available to assist. They offer 24/7 phone support and provide online resources, including user manuals, troubleshooting guides, and software updates (if applicable). For on – site support, ABB’s certified technicians can be dispatched to help with installation, commissioning, and maintenance. In the event of a failure, ABB aims to resolve the issue as quickly as possible, minimizing downtime for the customer. Additionally, ABB is committed to long – term availability of spare parts for the board, ensuring that customers can continue to rely on it for their industrial applications for an extended period.