Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

|---|---|

| Product model | ABB BSD0750 |

| Manufacturer | ABB |

| Product category | Servo Drive |

| Rated Power | 750 W |

| Rated Current | 750 A |

| Short-Circuit Breaking Capacity | 40 kA |

| Operating Voltage | 200-230 VAC |

| Continuous Output Current | 4.8 A |

| Peak Torque | 3.2 Nm |

| Control Method | Vector Control |

| Communication Protocols | EtherCAT, Modbus, CANopen |

| Display Resolution | 131.072 pulses/second |

| Dimensions | 240 mm (W) x 180 mm (H) x 120 mm (D) |

| Weight | 5 kg |

| Operating Temperature | 0°C to 50°C |

| Humidity Range | 5% to 95% RH (non-condensing) |

| Protection Rating | IP20 |

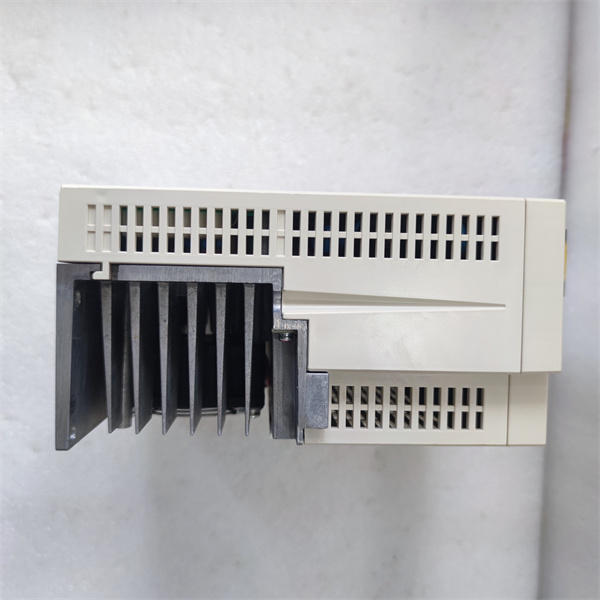

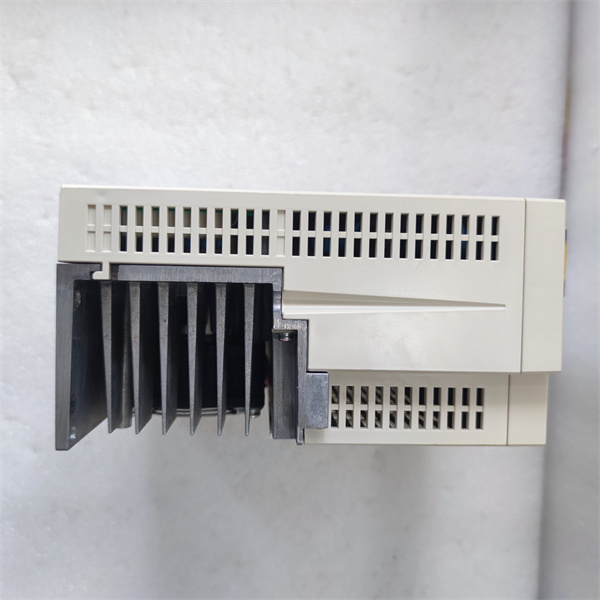

ABB BSD0750

Product Introduction

The ABB BSD0750 is a high-performance servo drive designed for precise control of motor speed, position, and torque. It belongs to ABB’s BSD series and is widely used in industrial automation applications requiring high precision and reliability. The BSD0750 features advanced vector control technology, providing stable and efficient performance in demanding environments.

Core Advantages and Technical Highlights

High Precision Control: The BSD0750 offers precise position, speed, and torque control, making it suitable for applications with high dynamic response requirements. It supports multiple control modes, including position, speed, and torque control.

Robust Design: Designed for industrial environments, the BSD0750 features a compact size and IP20 protection rating, ensuring durability and reliability. It supports a wide operating temperature range and has built-in protection functions such as overload, overvoltage, and overtemperature protection.

Flexible Integration: The BSD0750 supports multiple communication protocols, including EtherCAT, Modbus, and CANopen, facilitating seamless integration with various automation systems. Its modular design allows for easy installation, maintenance, and upgrades.

User-Friendly Interface: The drive features a high-resolution display and intuitive configuration software, simplifying the installation and commissioning process. It also supports multiple languages and provides detailed diagnostic information.

ABB BSD0750

Typical Application Scenarios

The ABB BSD0750 is widely used in various industrial sectors:

-

Industrial Automation: Used in manufacturing lines, robotic systems, and CNC machines for precise motion control.

-

Semiconductor Manufacturing: Employed in wafer cutting and SMT placement machines.

-

Automotive Manufacturing: Used in welding, painting, and assembly lines.

-

Packaging and Textile Industries: Used in packaging machines, sewing machines, and textile equipment.

Related Model Recommendations

-

ABB ACS880 MD Drive Section: A powerful drive system that can be integrated with the BSD0750 for advanced motion control.

-

ABB AC800M: A versatile PLC controller that can be paired with the BSD0750 for comprehensive automation control.

-

ABB AI810: An analog input module for precise data acquisition, suitable for monitoring drive systems.

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Ensure the environment meets the specified temperature and humidity requirements (0°C to 50°C, 5% to 95% RH non-condensing). Use shielded cables and proper grounding to minimize electromagnetic interference. Follow ABB’s guidelines for panel mounting, ensuring proper ventilation and protection from dust.

Maintenance Suggestions: Regularly inspect connections for wear and clean the drive with a static-free cloth to ensure optimal heat dissipation. Use ABB’s dedicated software for drive configuration and firmware updates. Follow ABB’s guidelines for handling sensitive components, including anti-static measures during maintenance.

Service and Guarantee Commitment

ABB stands behind the quality and reliability of the ABB BSD0750, offering a comprehensive warranty that covers manufacturing defects and performance issues for a specified period. Our dedicated after-sales support team is available to assist with technical inquiries and provide prompt solutions to ensure minimal disruption to your operations.