Description

Detailed parameter table

| Parameter name | Parameter value |

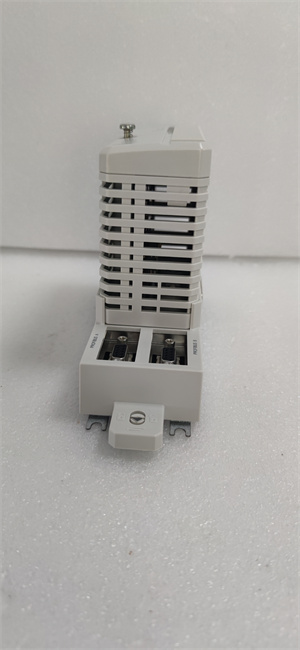

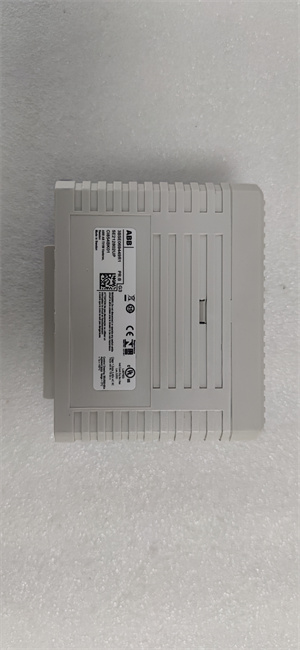

| Product model | CI854BK01 |

| Manufacturer | ABB |

| Product category | Communication Interface Module |

| Communication protocol | Supports PROFIBUS – DP/V1, also Modbus TCP and Ethernet/IP |

| Communication speed | Up to 12Mbit/s |

| Power voltage | 24V DC |

| Physical size (净深 / 净高 / 净宽) | 127.5mm/185mm/59mm |

| Weight | Approximately 0.59 kg |

| Working temperature range | – 20°C to + 60°C |

| Protection level | IP65 |

| Interface type | PROFIBUS DP with DB female (9 – pin) connector |

ABB CI854BK01

Product introduction

The ABB CI854BK01 is a high – performance communication interface module, an integral part of ABB’s comprehensive industrial automation product lineup. This module is designed to play a crucial role in enabling seamless communication within industrial automation systems.

It serves as a bridge between different devices, allowing for the transfer of data at high speeds. The CI854BK01 is specifically engineered to support the PROFIBUS – DP/V1 protocol, which is widely used in industrial settings for connecting various field devices such as remote I/O units, drives, and low – voltage electrical equipment. Additionally, its compatibility with Modbus TCP and Ethernet/IP further expands its application scope, making it suitable for integration into diverse automation architectures. As part of ABB’s commitment to providing reliable and advanced automation solutions, the CI854BK01 is a key component for enhancing the communication capabilities of industrial control systems.

Core advantages and technical highlights

High – speed communication

The ABB CI854BK01 can achieve data transfer speeds of up to 12Mbit/s. This high – speed performance ensures that in industrial processes where real – time data exchange is critical, such as high – speed manufacturing lines or complex process control systems, the module can quickly transmit and receive information. For example, in a fast – paced automotive assembly line, it enables immediate communication between robotic arms, sensors, and controllers, optimizing the production flow.

Redundancy features

It has a dual – channel design with two PROFIBUS ports, which can be utilized to implement line redundancy. In case one communication line fails, the system can automatically switch to the other, ensuring continuous data transfer. Moreover, the module supports PROFIBUS master station redundancy. This means that if the primary master station encounters issues, the backup master can take over, significantly enhancing the overall reliability and fault – tolerance of the industrial communication network.

Wide – ranging compatibility

With support for multiple communication protocols like PROFIBUS – DP/V1, Modbus TCP, and Ethernet/IP, the CI854BK01 can interface with a vast array of devices from different manufacturers. This compatibility simplifies the integration process in complex industrial automation projects, where there may be a mix of legacy and new – generation equipment. It reduces the need for multiple specialized communication gateways, streamlining the system architecture.

Rugged construction

Designed to endure harsh industrial environments, the CI854BK01 has an IP65 protection level. This means it is highly resistant to dust and water, suitable for use in factories with high – dust conditions or areas where water splashing may occur. The wide working temperature range from – 20°C to + 60°C also ensures its proper operation in various climate conditions, whether in cold storage facilities or hot processing plants.

Typical application scenarios

In the manufacturing industry, the ABB CI854BK01 is extensively used. In large – scale automotive manufacturing plants, it enables communication between the central control system and numerous distributed devices on the production line. It coordinates the actions of conveyor belts, robotic welders, and painting robots, ensuring smooth and synchronized operations. The high – speed and reliable communication of the CI854BK01 are vital for maintaining the high – volume production requirements.

In the process control industry, such as in chemical plants, the module is used to connect field sensors and actuators to the control room. It receives data from sensors monitoring parameters like temperature, pressure, and flow rate, and transmits control commands to valves and pumps. The redundancy features of the CI854BK01 are particularly important in these applications, as any interruption in communication could lead to safety hazards and production losses.

In the power generation sector, the CI854BK01 plays a role in connecting different components of the power generation system. It allows for communication between turbines, generators, and monitoring systems, ensuring stable power output. The module’s ability to operate in a wide temperature range makes it suitable for use in power plants, where the environment can be challenging.

Related model recommendations

CI854AK01: It is from the same series of ABB communication interface modules. Similar to the CI854BK01, it also supports PROFIBUS – DP/V1. However, it may have some differences in specific configurations or performance optimizations, making it suitable for different subsets of industrial applications, perhaps with a focus on more cost – effective solutions for less complex systems.

CI860K01: This module is designed for different communication protocols, such as Foundation Fieldbus. While the CI854BK01 is centered around PROFIBUS – DP/V1 and related protocols, the CI860K01 can be used in systems where Foundation Fieldbus – based devices are dominant. In some cases, they can be used together in a larger industrial network to handle communication for different types of field devices.

AC 800M CPU modules: These CPU modules are part of the ABB AC 800M control system. The CI854BK01 can be integrated with AC 800M CPU modules to form a complete control and communication solution. The CPU modules handle the overall control logic, while the CI854BK01 takes care of the communication with external field devices, working in tandem to optimize industrial processes.

S800 I/O modules: ABB’s S800 I/O modules can be connected to the CI854BK01. The I/O modules are responsible for interfacing with sensors and actuators in the field. The CI854BK01 enables communication between these I/O modules and the rest of the control system, ensuring seamless data transfer between the physical devices and the central control unit.

BC810: This is a CEXbus redundancy module. In systems where high – level redundancy is required, the CI854BK01 can be combined with the BC810. The BC810 provides CEXbus redundancy, and when used with the CI854BK01‘s line and master station redundancy features, it creates a highly reliable industrial communication and control infrastructure.

ABB CI854BK01

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the ABB CI854BK01, ensure that the installation area is clean and free from excessive dust, moisture, and strong electromagnetic fields. Gather standard installation tools like screwdrivers and wire crimpers. Safety is paramount; turn off all relevant power sources in the installation area. When handling the module, follow anti – static procedures to prevent electrostatic discharge from damaging the sensitive electronic components. The module is designed for DIN – rail mounting, so make sure the DIN – rail is securely installed and of the appropriate size.

Maintenance suggestions

For daily maintenance, regularly check the status indicators on the CI854BK01 to ensure normal operation. If any error lights are illuminated, refer to the detailed user manual for troubleshooting steps. In case a module replacement is needed, first, disconnect the power. The CI854BK01 supports hot – swap functionality for some applications, but for safety and to avoid potential data corruption, it is advisable to power – down the system when possible. Keep spare CI854BK01 modules in stock, along with any necessary connection cables. Periodically clean the module to remove dust, as excessive dust accumulation can affect its performance, especially in high – dust industrial environments.

Service and guarantee commitment

ABB stands firmly behind the quality of the CI854BK01 communication interface module. We offer a comprehensive quality assurance program, ensuring that the product adheres to the highest industry standards. Our global service network is at your disposal for any after – sales support. In case of issues, our experienced service engineers can provide both on – site and remote assistance.

We guarantee fast response times, especially during critical situations, to minimize any potential downtime of your industrial automation system. Our technicians are highly trained in ABB products, including the CI854BK01, and can offer in – depth technical support. Additionally, we regularly release software updates to enhance the module’s performance, functionality, and compatibility with new devices and systems. With ABB, you can have full confidence in the long – term reliability and support for your CI854BK01 – based industrial communication infrastructure.