Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

|---|---|

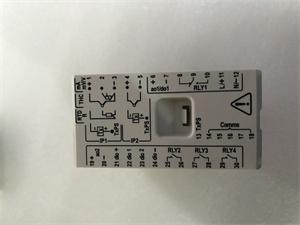

| Product model | ABB CM10 |

| Manufacturer | ABB |

| Product category | Universal PID Process Controller |

| Display type | Full-color 5.5 cm (2.2″) TFT LCD display |

| Electrical performance | 100-240 V AC ±10%, 50/60 Hz; 10-36 V DC (optional) |

| Physical size | 50 x 97 x 141 mm (2.0 x 3.8 x 5.5 in.) |

| Interface type | Front panel menus, PC configuration software, IrDA service port |

| Communication protocol | MODBUS RTU, Ethernet (optional) |

| Environmental requirements | Operating temperature: 0 to 55°C; Humidity: 5 to 95% RH (non-condensing) |

| Installation method | Panel mount |

| Performance indicators | Auto-tuning, split output control, 8 independent process alarms |

ABB CM10

Product Introduction

The ABB CM10 is a versatile and scalable universal PID process controller designed for a wide range of industrial applications. It features a full-color 5.5 cm (2.2″) TFT display that provides clear and detailed process information, including alarm messages and diagnostic data, all at a glance. This intuitive user interface simplifies installation, commissioning, and operation, making the ABB CM10 an ideal choice for both simple and complex control tasks.

The ABB CM10 is part of the ControlMaster series, known for its flexibility and adaptability. It offers a variety of control strategies, including on/off, time proportioning, analog PID, and split output control, ensuring precise process management. The controller’s hardware and software are both scalable, allowing it to be customized to meet specific application requirements. Its advanced auto-tuning functionality further enhances its performance by automatically calculating the optimal PID values for quick and efficient commissioning.

In an automation system, the ABB CM10 serves as a reliable and intelligent control unit. It can be easily integrated into larger control systems through its MODBUS and Ethernet communication options, providing seamless connectivity and data exchange. With its robust IP66 and NEMA 4X enclosure, the ABB CM10 is designed to withstand harsh industrial environments, ensuring long-term reliability and performance.

Core Advantages and Technical Highlights

The ABB CM10 stands out in the market due to its innovative features and superior performance. Its full-color TFT display and intuitive user interface make process monitoring and control incredibly straightforward. The controller’s ability to support multiple control strategies, including analog PID and split output control, makes it suitable for a wide range of applications.

Reliable and Stable: The ABB CM10 is built with high-quality components and designed to operate reliably in harsh industrial environments. Its IP66 and NEMA 4X enclosure ensures protection against dust, water, and other contaminants. The controller also features advanced auto-tuning capabilities, which automatically calculate the optimal PID values for precise control.

Flexible and Scalable: The ABB CM10 offers both hardware and software scalability, allowing it to be easily customized to meet specific application needs. Users can add functionality through optional modules and templates, ensuring that the controller grows with their requirements.

Easy to Use: The intuitive user interface of the ABB CM10 simplifies configuration and operation. The full-color TFT display provides clear and detailed information, while the easy-to-navigate menus make setup and monitoring a breeze. The controller can also be configured using PC software, further enhancing its ease of use.

Advanced Communication: The ABB CM10 supports multiple communication protocols, including MODBUS RTU and Ethernet, ensuring seamless integration into larger control systems. This allows for efficient data exchange and remote monitoring, enhancing overall system performance.

ABB CM10

Typical Application Scenarios

The ABB CM10 is widely used across various industries due to its versatility and reliability. In the manufacturing sector, it is employed for temperature control in ovens and furnaces, ensuring precise heating and cooling processes. In the food and beverage industry, the ABB CM10 is used for controlling the temperature and humidity in storage facilities, maintaining optimal conditions for product quality.

In chemical processing plants, the ABB CM10 is utilized for flow control and pressure regulation, ensuring safe and efficient operations. Its ability to handle multiple control strategies and provide detailed process information makes it an ideal solution for complex industrial processes. Additionally, the ABB CM10 is often used in HVAC systems for precise temperature and humidity control, enhancing comfort and energy efficiency.

Related Model Recommendations

-

ABB CM30: A larger 1/4 DIN process controller that offers more advanced features and additional I/O options. It is suitable for applications requiring more complex control strategies and multiple control loops.

-

ABB CM50: A 1/2 DIN process controller designed for large-scale industrial applications. It provides extensive control capabilities and is ideal for multi-loop control and advanced process management.

-

ABB CM10/0715: A DIN rail installation kit for the ABB CM10, allowing for easy and secure installation in control cabinets.

-

ABB CM30/0712: A PC configuration kit for the ABB CM30 series, enabling advanced configuration and customization.

-

ABB ENG/CON: An engineering configuration service for customizing the ABB CM10 to meet specific application requirements.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the ABB CM10, ensure that the environment meets the specified requirements, including an operating temperature range of 0 to 55°C and humidity levels between 5% and 95% RH (non-condensing). The installation location should be free from excessive dust, moisture, and corrosive gases to ensure long-term reliability. Use the provided panel installation kit to secure the controller in place, ensuring that the panel cutout dimensions of 45 x 92 mm (1.8 x 3.6 in.) are accurately measured. Always follow the manufacturer’s guidelines for proper installation to avoid damage to the device.

Maintenance Suggestions

To maintain the ABB CM10, perform regular inspections of the controller and its connections to ensure they are secure and free from corrosion. Clean the display and enclosure regularly with a soft, dry cloth to remove dust and debris. If any issues arise, refer to the troubleshooting guide in the user manual for common solutions. Replace any worn or damaged parts promptly to ensure continued performance. Regularly update the firmware to benefit from the latest enhancements and security features. By following these maintenance tips, you can ensure the long-term reliability and optimal performance of the ABB CM10.

Service and Guarantee Commitment

The ABB CM10 is backed by ABB’s commitment to quality and customer satisfaction. ABB offers a comprehensive warranty that covers manufacturing defects and ensures the product meets the highest standards of reliability. In addition to the warranty, ABB provides extensive after-sales support, including technical assistance and spare parts availability. This commitment ensures that customers receive reliable and efficient support throughout the product’s lifecycle, giving them confidence in their investment.