Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

|---|---|

| Product model | ABB CMA132 |

| Manufacturer | ABB |

| Product category | Industrial Control Module |

| Operating Voltage | 220 V AC / 100-240 V AC / 24 V DC |

| Input Type | Digital / Various (Thermocouple, RTD, mV, mA, V, Potentiometer) |

| Relay Outputs | 2 |

| Output Frequency | 50 kHz |

| Certification | ISO 9001:2015 / CE, RoHS |

| Series | CMA132 3DDE300412 |

| Material Coding | CMA132 3DDE300412 |

| Dimensions | 100 mm x 60 mm x 30 mm / 170 mm x 100 mm |

| Weight | 0.2 kg / 0.3 kg |

| Operating Temperature | -20°C to +70°C / -40°C to +85°C |

| Storage Temperature | -40°C to +85°C |

| Protection Class | IP20 / IP54 |

| Communication Protocols | Modbus RTU / Modbus TCP/IP |

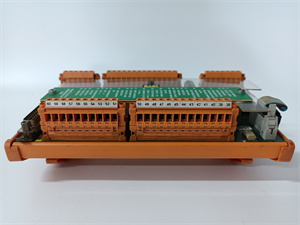

ABB CMA132

Product Introduction

The ABB CMA132 is a high-performance industrial control module designed for seamless integration into complex industrial automation systems. It serves as a critical component for monitoring, controlling, and protecting industrial processes, particularly in power generation and distribution applications. The module features advanced capabilities for signal processing, relay control, and communication, ensuring precise and reliable operation in demanding environments.

Core Advantages and Technical Highlights

High Precision and Reliability: The ABB CMA132 is engineered with high-quality components and advanced manufacturing techniques, ensuring reliable performance and long service life. It features dual high-speed relay outputs for precise control and monitoring of industrial processes.

Versatile Communication Options: The module supports multiple communication protocols, including Modbus RTU and Modbus TCP/IP, enabling seamless integration with various industrial networks and systems.

Robust Design: The ABB CMA132 is built to withstand harsh industrial conditions, with a protection class of IP20 or IP54, depending on the variant. Its compact size and lightweight design make it easy to install and integrate into existing systems.

User-Friendly Interface: The module features an intuitive interface and comprehensive documentation, simplifying installation, configuration, and maintenance. This reduces downtime and minimizes the need for extensive training.

Advanced Diagnostics: The ABB CMA132 includes diagnostic features that provide real-time status monitoring and quick fault identification, reducing maintenance costs and improving system reliability.

ABB CMA132

Typical Application Scenarios

The ABB CMA132 is widely used in various industrial sectors, including power generation, chemical processing, water treatment, and manufacturing. In power plants, it is employed for generator protection and control, ensuring smooth transitions and optimal load management. In industrial automation, it serves as a key component for signal transmission, control signal output, data acquisition, and fault diagnosis. The module’s ability to operate in a wide temperature range and its compact design make it suitable for both indoor and outdoor applications.

Related Model Recommendations

-

ABB CMA120: A basic controller panel unit, suitable for simpler applications.

-

ABB CMA126: An interface card for industrial automation, offering versatile communication options.

-

ABB CM579-PNIO: A PROFINET IO communication module that can be used alongside the ABB CMA132 for enhanced connectivity.

-

ABB AC800F: A controller series that works seamlessly with the ABB CMA132, providing a comprehensive automation solution.

-

ABB PM595-4ETH: An Ethernet communication module that can be used for additional connectivity options.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the ABB CMA132, ensure that the environment meets the specified requirements, including an operating temperature range of -20°C to +70°C. The installation location should be free from excessive dust, moisture, and corrosive gases to ensure long-term reliability. Use a standard DIN rail or panel mount for secure installation.

Maintenance Suggestions

To maintain the ABB CMA132, perform regular inspections of the module and its connections to ensure they are secure and free from corrosion. Clean the unit regularly with a soft, dry cloth to remove dust and debris. If any issues arise, refer to the troubleshooting guide in the user manual for common solutions. Replace any worn or damaged parts promptly to ensure continued performance. Regularly update the firmware to benefit from the latest enhancements and security features. By following these maintenance tips, you can ensure the long-term reliability and optimal performance of the ABB CMA132.

Service and Guarantee Commitment

The ABB CMA132 is backed by ABB’s commitment to quality and customer satisfaction. ABB offers a comprehensive warranty that covers manufacturing defects and ensures the product meets the highest standards of reliability. In addition to the warranty, ABB provides extensive after-sales support, including technical assistance and spare parts availability. This commitment ensures that customers receive reliable and efficient support throughout the product’s lifecycle, giving them confidence in their investment.