Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

|---|---|

| Product model | ABB DDC779BE02 3BHE006805R0002 |

| Manufacturer | ABB |

| Product category | Distributed Control System (DCS) PLC Module |

| Input voltage range | 24V DC |

| Operating voltage | 220V AC |

| Output voltage | 24V DC |

| Output frequency | 30kHz |

| Power consumption | 2W |

| Processor | 1.6 GHz ARM Cortex-A9 dual-core processor |

| Memory | 512 MB DDR3 RAM |

| Storage | 2 GB eMMC flash |

| Communication protocols | Modbus, Profibus, Ethernet/IP, ABB proprietary protocols |

| Operating temperature | -40°C to +85°C |

| Humidity | 5% to 95% non-condensing |

| Protection class | IP20 |

| Dimensions | 48×48×110 mm or 150 x 100 x 30 mm |

| Weight | 0.5 kg or 2.2 kg |

| Certifications | CE, RoHS |

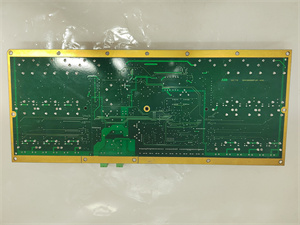

DDC779BE02 3BHE006805R0002

Product Introduction

The ABB DDC779BE02 3BHE006805R0002 is a high-performance Distributed Control System (DCS) PLC module designed for industrial automation and process control applications. It is part of ABB’s 800xA control system, a sophisticated and flexible platform that ensures seamless integration of various control and automation processes within industries like chemical production, oil & gas, power generation, and manufacturing. This module is engineered to provide real-time data processing, high reliability, and scalability for complex process control systems.

Core Advantages and Technical Highlights

Real-Time Process Control: The DDC779BE02 module is optimized for real-time control, providing low-latency response times necessary for applications requiring fast control of critical parameters like temperature, pressure, and flow.

High Redundancy: With built-in redundant power supplies, communication networks, and I/O modules, the system ensures high reliability and minimizes downtime, which is critical in mission-critical environments.

Flexible and Scalable: The modular design supports easy system expansion by adding more I/O modules, communication ports, or power supplies to meet the growing needs of complex industrial automation systems.

Seamless Integration with ABB Systems: It integrates smoothly with ABB 800xA control systems, leveraging ABB’s powerful automation and control technologies for enhanced performance and reduced system integration time.

Comprehensive Diagnostics and Maintenance: The module includes built-in diagnostic tools, allowing users to quickly identify and troubleshoot system faults. This reduces maintenance costs and improves operational efficiency.

DDC779BE02 3BHE006805R0002

Typical Application Scenarios

The ABB DDC779BE02 3BHE006805R0002 is widely used in various industrial sectors, including:

-

Power Generation: Controlling turbines, boilers, and generators in thermal, nuclear, and hydroelectric plants.

-

Oil & Gas: Monitoring pipeline systems, controlling refinery operations, and managing offshore platforms.

-

Chemical Processing: Managing complex chemical processes like distillation, reaction control, and batch processing in chemical production environments.

-

Manufacturing: Controlling automated manufacturing systems, including robotic arms, conveyor belts, and assembly lines in factories.

-

Water Treatment: Managing wastewater treatment, filtration, chemical dosing, and flow regulation in municipal water treatment plants.

Related Model Recommendations

-

ABB 800xA Series: Other modules in the ABB 800xA series that can be integrated with the DDC779BE02 for comprehensive automation solutions.

-

ABB ACS880 Drives: Compatible with the DDC779BE02 for precise motor speed and torque regulation.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the ABB DDC779BE02 3BHE006805R0002, ensure that the environment meets the specified requirements, including an operating temperature range of -40°C to +85°C. The installation location should be free from excessive dust, moisture, and corrosive gases to ensure long-term reliability. Use a standard DIN rail or rack mount for secure installation.

Maintenance Suggestions

To maintain the ABB DDC779BE02 3BHE006805R0002, perform regular inspections of the module and its connections to ensure they are secure and free from corrosion. Clean the unit regularly with a soft, dry cloth to remove dust and debris. If any issues arise, refer to the troubleshooting guide in the user manual for common solutions. Replace any worn or damaged parts promptly to ensure continued performance.