Description

| Parameter name | Parameter value |

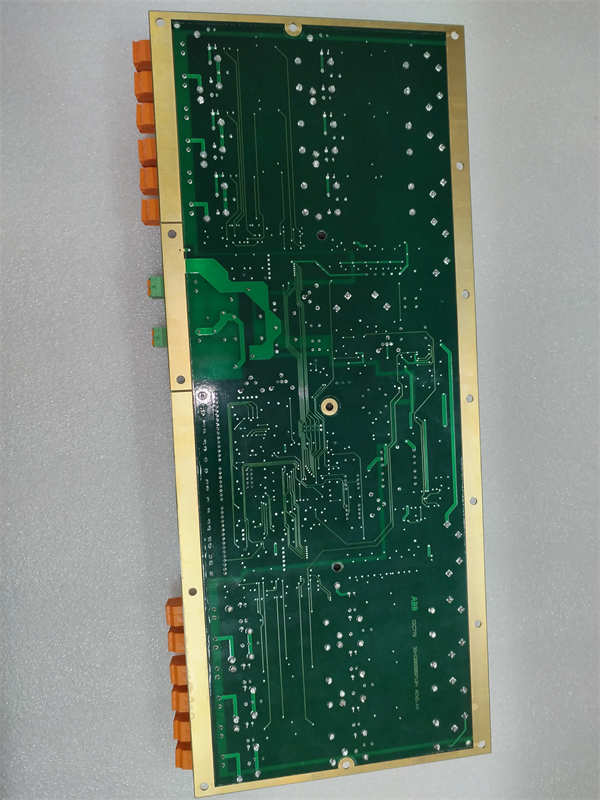

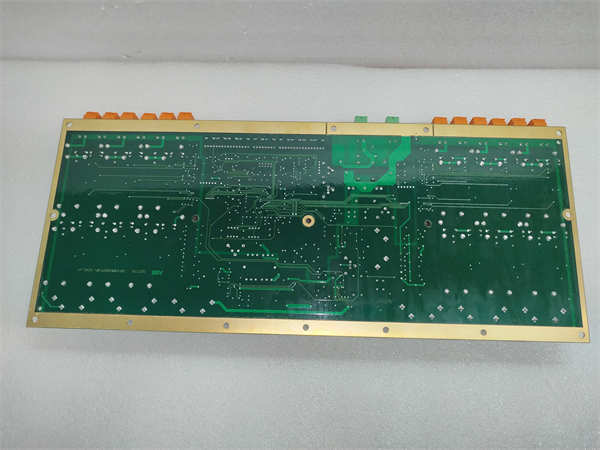

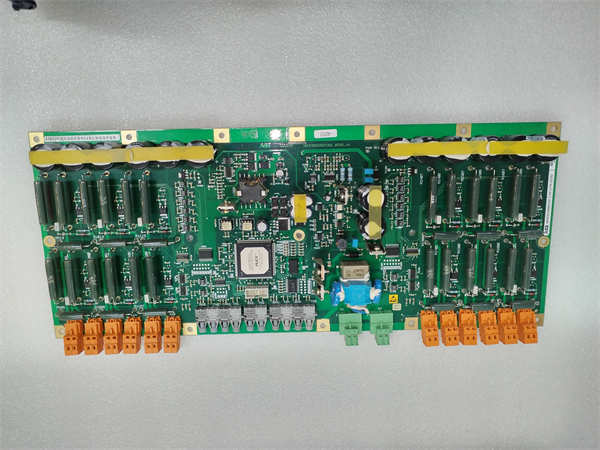

| Product model | DDC779CE102 3BHE027859R0102 |

| Manufacturer | ABB |

| Product category | Distributed digital control module for industrial processes |

| Processing capacity | 32-bit ARM Cortex-M4 processor, 168 MHz |

| I/O configuration | 16 analog inputs (4-20 mA, 0-10 V); 8 analog outputs (4-20 mA); 32 digital inputs (24 VDC); 16 digital outputs (24 VDC, 5 A) |

| Memory | 512 MB RAM; 2 GB flash storage |

| Communication protocols | BACnet/IP, Modbus TCP, Profinet, Ethernet/IP |

| Power supply | 24 VDC ±15%, 30 W max |

| Operating temperature | -10°C to +60°C |

| Dimensions (WxHxD) | 180 mm x 120 mm x 85 mm |

| Protection class | IP20 (module); IP42 (with optional enclosure) |

| Certifications | IEC 61131-3, CE, UL 61010-1, RoHS |

ABB DDC779CE102 3BHE027859R0102

Product introduction

The DDC779CE102 3BHE027859R0102 is a high-performance distributed digital control module from ABB, designed to manage complex industrial processes with precision and flexibility. As a key component in ABB’s Freelance DCS system, it bridges field devices and central control systems, enabling real-time monitoring and control of diverse process variables.

This module combines robust processing power with extensive I/O capabilities, making it suitable for applications ranging from building automation to industrial manufacturing. The DDC779CE102 3BHE027859R0102 executes advanced control algorithms—including PID, fuzzy logic, and sequential control—while maintaining seamless communication with supervisory systems. Its scalable design allows integration into both small-scale control loops and large distributed networks, providing consistent performance across various industrial environments.

Core advantages and technical highlights

High-speed processing: Equipped with a 168 MHz ARM Cortex-M4 processor, the DDC779CE102 3BHE027859R0102 processes 10,000+ I/O points per second. In a semiconductor cleanroom, this speed enabled simultaneous regulation of 20 temperature zones with ±0.1°C accuracy, critical for wafer production yield.

Multi-protocol compatibility: Support for BACnet/IP, Modbus TCP, and Profinet ensures interoperability. A pharmaceutical plant used the module to connect legacy Modbus sensors with a new BACnet-based building management system, avoiding costly hardware replacements and reducing integration time by 40%.

Redundant architecture: Optional dual power supplies and communication ports minimize downtime. A data center leveraged this feature to maintain uninterrupted cooling control during a power supply failure, preventing server overheating and potential data loss.

Edge computing capabilities: Onboard 2 GB flash storage enables local data logging and analytics. A food processing plant used the DDC779CE102 to store 30 days of temperature and pressure data, facilitating compliance with FDA regulations and enabling root-cause analysis of process deviations without relying on cloud connectivity.

Typical application scenarios

Industrial HVAC: In a large automotive factory, the DDC779CE102 3BHE027859R0102 controls heating, ventilation, and air conditioning across 12 production zones. It adjusts airflow rates based on occupancy sensors (digital inputs) and temperature readings (analog inputs), reducing energy consumption by 18% compared to legacy systems. Its Ethernet/IP connection to the plant’s SCADA system allows centralized monitoring of HVAC performance.

Water treatment: A municipal wastewater treatment plant uses the DDC779CE102 to automate filtration and chemical dosing. Analog inputs monitor turbidity and pH levels, while analog outputs regulate dosing pumps. Sequential control logic triggers backwash cycles based on pressure differentials, ensuring filter efficiency. The module’s Profinet interface connects to variable frequency drives (VFDs) controlling pumps, enabling smooth speed adjustments and energy savings.

Building automation: A luxury hotel complex employs the DDC779CE102 3BHE027859R0102 to manage lighting, climate, and security systems. Digital outputs control lighting circuits based on occupancy, while analog outputs adjust room temperatures via thermostats. BACnet/IP communication integrates with the hotel’s property management system, allowing guest-specific climate settings and reducing energy waste in unoccupied rooms.

ABB DDC779CE102 3BHE027859R0102

Related model recommendations

DDC770CE101: Entry-level variant with 8 analog inputs, ideal for small-scale applications like retail store climate control.

DDC780CE103: Advanced model with 24 analog inputs and 5G connectivity, suitable for remote industrial sites requiring high bandwidth.

CI867K01: Communication extension module for DDC779CE102, adding support for IEC 60870-5-104 protocol for utility applications.

AI880: Analog input expansion module, doubling the DDC779CE102‘s sensor capacity for complex process monitoring.

DO880: High-power digital output module, enabling the DDC779CE102 to control large motors and heaters up to 230 VAC.

HMI770: 7-inch touchscreen panel paired with DDC779CE102, providing local control and real-time data visualization.

DDC-CONFIG: ABB’s configuration software for DDC779CE102, simplifying programming of control logic and communication settings.

Installation, commissioning and maintenance instructions

Installation preparation: Mount DDC779CE102 3BHE027859R0102 on a 35mm DIN rail in a control cabinet, ensuring 100mm clearance for ventilation. Use 0.5mm² shielded twisted-pair cables for analog signals, grounding shields at both ends to reduce noise. Terminate digital I/O with 0.75mm² wires, torquing terminals to 0.8 Nm. Verify 24 VDC power supply stability before connection—install surge protection (ABB part 3HAC064789-001) in high-noise environments.

Maintenance suggestions: Inspect quarterly for dust accumulation and loose connections; clean with compressed air. Calibrate analog inputs annually using a precision signal generator, verifying accuracy at 25%, 50%, and 75% of full scale. Update firmware via ABB’s AssetVision software to access new features. Replace lithium backup battery (CR2032) every 5 years to preserve configuration during power loss. For communication issues, use ABB’s Network Diagnostics Tool to check protocol traffic and signal strength.

Service and guarantee commitment

ABB backs the DDC779CE102 3BHE027859R0102 with a 5-year warranty covering manufacturing defects. During this period, ABB provides free replacement of faulty modules and 24/7 technical support via phone and email, with average response times under 2 hours.

Customers receive lifetime access to firmware updates, configuration tools, and technical documentation through ABB’s Industrial Automation Portal. Optional services include on-site commissioning with IEC 61508 functional safety verification and operator training. ABB guarantees spare parts availability for 15 years post-production, ensuring long-term support for critical infrastructure. This commitment reflects confidence in the module’s reliability and dedication to minimizing process interruptions.