Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

|---|---|

| Product model | ABB HIEE401782R0001 LTC391AE01 |

| Manufacturer | ABB |

| Product category | High-Precision Industrial Control Module |

| Input voltage range | 24V DC ±20% |

| Output voltage | 24V DC |

| Maximum load current | 5A |

| Operating temperature | -40°C to +85°C |

| Storage temperature | -55°C to +125°C |

| Humidity | 5% to 95% non-condensing |

| Protection class | IP20 |

| Dimensions | 140 mm x 200 mm x 60 mm |

| Weight | 1.2 kg |

| Communication protocols | Modbus, Profibus, TCP/IP, EtherCAT, SERCOS III |

| Certifications | CE, UL, ISO 14644-1 (cleanroom compliant) |

| Function blocks supported | Up to 30,000 function blocks |

| Power consumption | 20W typical |

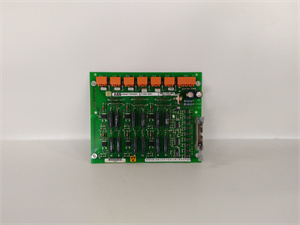

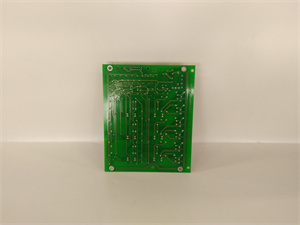

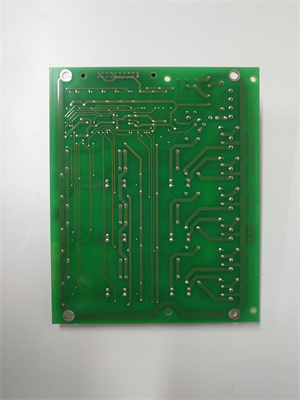

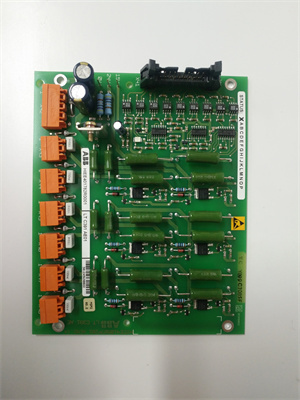

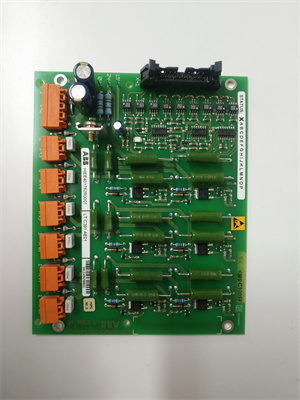

ABB HIEE401782R0001 LTC391AE01

Product Introduction

The ABB HIEE401782R0001 LTC391AE01 is a high-precision industrial control module designed for advanced automation applications. It is part of ABB’s extensive lineup of automation products, known for their reliability and advanced technology. This module offers precise control and monitoring capabilities, ensuring optimal performance and efficiency in demanding industrial environments.

Core Advantages and Technical Highlights

Advanced Control Algorithms: The LTC391AE01 employs model predictive control (MPC) algorithms to handle dead-time-dominated processes, significantly improving response times and control accuracy.

High Precision: The module supports high-precision control with ±0.1% accuracy, making it suitable for applications requiring sub-micron positioning accuracy.

Robust Design: The module is built to withstand harsh industrial environments, with a durable casing that protects against dust, moisture, and extreme temperatures.

Flexible Communication Interfaces: The LTC391AE01 supports multiple communication protocols, including Modbus, Profibus, TCP/IP, EtherCAT, and SERCOS III, ensuring seamless integration with existing industrial networks.

User-Friendly Interface: The intuitive interface simplifies operation, allowing users to easily navigate through settings and configurations.

Safety Features: The module includes built-in safety functions such as safe torque off (STO) and safe stop 1 (SS1), compliant with ISO 13849-1 (PLd), making it suitable for collaborative robotics and human-robot interaction scenarios.

Compact Design: The module’s compact form factor and fanless design make it ideal for space-constrained cleanroom environments (e.g., ISO Class 5), where dust and particle generation must be minimized.

ABB HIEE401782R0001 LTC391AE01

Typical Application Scenarios

The ABB HIEE401782R0001 LTC391AE01 is widely used in various industrial sectors, including:

-

Manufacturing: Ideal for automation tasks in manufacturing facilities, helping to streamline production processes and improve efficiency.

-

Oil and Gas: Well-suited for use in the oil and gas industry, where precise control and monitoring are essential for safe and efficient operations.

-

Power Generation: Can be used in power generation plants to automate various processes and ensure reliable operation.

-

Water Treatment: Suitable for automation tasks in water treatment facilities, where accurate control is crucial for maintaining water quality.

-

Semiconductor Manufacturing: Controls wafer handling robots, inspection stages, and die bonders, ensuring accurate placement of components during chip fabrication.

-

Electronics Assembly: Drives pick-and-place machines to position surface-mount devices (SMDs) with precision, reducing defects in PCBA production.

-

Medical Device Industry: Enables the assembly of microfluidic devices, surgical instruments, and diagnostic equipment, where dimensional accuracy is critical for product functionality.

Related Model Recommendations

-

ABB ACQ500-01E 3BSE042600R1: A servo drive specifically designed for use with the LTC391AE01, offering high-power density and EtherCAT connectivity.

-

ABB IRB 910INV: A collaborative industrial robot that integrates with the LTC391AE01 for precision assembly tasks in confined spaces.

-

ABB AM601 Encoder: A high-resolution optical encoder (1 nm resolution) compatible with the LTC391AE01 for closed-loop feedback.

-

ABB RobotStudio® Motion Control Add-On: Software extension for programming and simulating linear motor trajectories with the LTC391AE01.

-

ABB SafeMove2 Software: A safety software package that enhances the LTC391AE01’s safety features for collaborative applications.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the ABB HIEE401782R0001 LTC391AE01, ensure that the environment meets the specified requirements, including an operating temperature range of -40°C to +85°C. The installation location should be free from excessive dust, moisture, and corrosive gases to ensure long-term reliability. Use a standard DIN rail or panel mount for secure installation.

Maintenance Suggestions

To maintain the ABB HIEE401782R0001 LTC391AE01, perform regular inspections of the module and its connections to ensure they are secure and free from corrosion. Clean the unit regularly with a soft, dry cloth to remove dust and debris. If any issues arise, refer to the troubleshooting guide in the user manual for common solutions. Replace any worn or damaged parts promptly to ensure continued performance.