Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

|---|---|

| Product model | ABB HPC800K02 |

| Manufacturer | ABB |

| Product category | High-Performance Industrial Controller |

| Processor | 32-bit PowerPC 603e or Intel Xeon E5-2600 v4 (depending on configuration) |

| Memory | 128 MB user memory, 16 MB user flash (basic model); 16GB-128GB DDR4 ECC (advanced model) |

| Communication protocols | Ethernet, RS-232/422/485, USB, Profibus DP, Modbus, EtherCAT, SERCOS III |

| Power supply | 24V DC ±20% |

| Operating temperature | -40°C to +85°C |

| Storage temperature | -55°C to +125°C |

| Humidity | 5% to 95% non-condensing |

| Protection class | IP20 |

| Dimensions | 129.03 mm (W) x 129.03 mm (H) x 32.26 mm (D) |

| Weight | 0.88 kg |

| Certifications | CE, UL, ISO 14644-1 (cleanroom compliant) |

| I/O points | Up to 24 I/O points |

| Function blocks supported | Up to 30,000 function blocks |

| Power consumption | 20W typical |

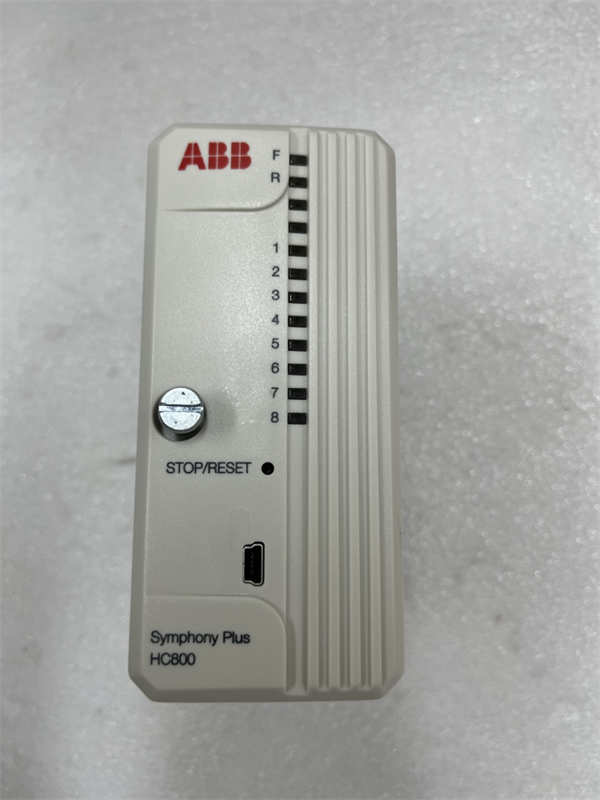

ABB HPC800K02

Product Introduction

The ABB HPC800K02 is a high-performance industrial controller designed for demanding automation applications. It is part of ABB’s AC800M series and is known for its robust control capabilities, reliability, and flexibility. This controller is ideal for applications requiring precise control, high reliability, and seamless integration with existing systems.

Core Advantages and Technical Highlights

High Performance and Reliability: The HPC800K02 features a powerful 32-bit PowerPC 603e processor and ample memory, ensuring efficient execution of control logic and real-time processing of input/output signals. Redundant design options enhance system availability and minimize downtime.

Scalability and Flexibility: The controller supports a wide range of I/O modules and communication protocols, facilitating seamless integration with diverse industrial equipment and systems. Modular architecture allows for easy expansion and customization to adapt to evolving process requirements.

Advanced Communication Capabilities: Integrated Ethernet, Profibus DP, RS-232/422/485, and other communication interfaces enable reliable data exchange with SCADA systems, PLCs, and other devices. It supports industry-standard protocols for interoperability with third-party equipment.

Enhanced Safety and Security: Built-in safety functions and compliance with industrial safety standards ensure the protection of personnel, equipment, and the environment. Robust security features safeguard against cyber threats, which are critical in today’s interconnected industrial landscapes.

User-Friendly Configuration and Maintenance: Intuitive software tools simplify controller programming, configuration, and troubleshooting, reducing setup time and operational complexity. Comprehensive diagnostics and fault-handling capabilities facilitate proactive maintenance and minimize downtime.

ABB HPC800K02

Typical Application Scenarios

The ABB HPC800K02 is widely used in various industrial sectors, including:

-

Power Generation and Distribution: Centralized control and monitoring of power plant operations.

-

Oil and Gas: Managing pipeline monitoring and refinery operations.

-

Water and Wastewater Treatment: Regulating water flow and treatment processes.

-

Chemicals and Petrochemicals: Controlling chemical reactions and material handling processes.

-

Pulp and Paper: Optimizing production lines and reducing operational costs.

-

Metals and Mining: Controlling heavy machinery and optimizing processes.

Related Model Recommendations

-

ABB AC800M Series: Other controllers in the AC800M series that can be used for similar applications.

-

ABB Symphony Plus: A comprehensive DCS system that the HPC800K02 integrates with for advanced control applications.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the ABB HPC800K02, ensure that the environment meets the specified requirements, including an operating temperature range of -40°C to +85°C. The installation location should be free from excessive dust, moisture, and corrosive gases to ensure long-term reliability. Use a standard DIN rail or panel mount for secure installation.

Maintenance Suggestions

To maintain the ABB HPC800K02, perform regular inspections of the module and its connections to ensure they are secure and free from corrosion. Clean the unit regularly with a soft, dry cloth to remove dust and debris. If any issues arise, refer to the troubleshooting guide in the user manual for common solutions. Replace any worn or damaged parts promptly to ensure continued performance.