Description

Detailed Parameter Table

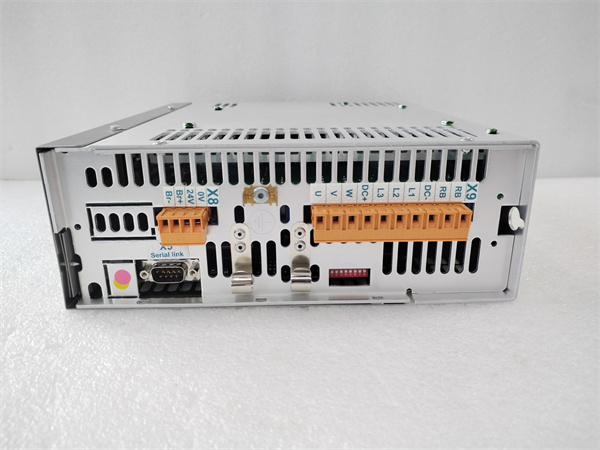

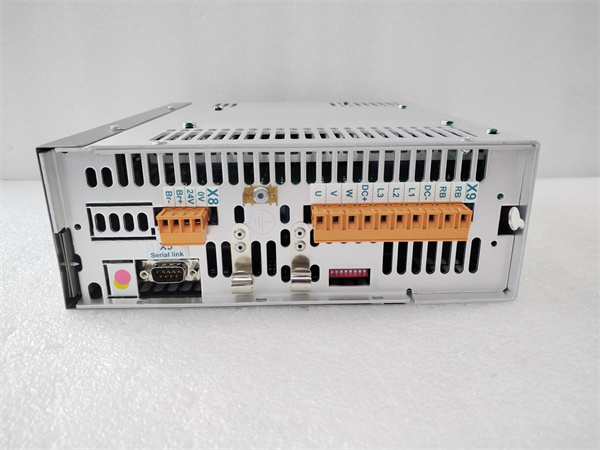

| Parameter Name | Parameter Value |

|---|---|

| Product model | ABB IMCAM07B0000 |

| Manufacturer | ABB |

| Product category | Industrial Communication and Control Module |

| Power supply | 24 VDC (±15%) / 110 VAC (50/60 Hz) |

| Working temperature | -40°C to 85°C |

| Installation method | DIN rail/panel installation |

| Physical size | 120 mm x 80 mm x 50 mm |

| Weight | 0.6 kg |

| Interface | 2x Ethernet (10/100/1000 Mbps), 4x RS-485, 2x USB 3.0 |

| Supported protocols | Modbus, Profibus, OPC UA, MQTT |

| Certifications | CE, UL, ATEX (Zone 2), IEC 61000-6 |

| Cooling method | Fanless conduction for heat dissipation |

| Protection level | IP67, IK08 (impact resistant) |

ABB IMCAM07B0000

Product Introduction

The ABB IMCAM07B0000 is a high-performance industrial communication and control module designed to bridge the gap between on-site devices and monitoring control layers. It serves as a data concentrator and protocol converter, supporting seamless integration between traditional devices and modern IIoT platforms. As part of a scalable automation suite such as ABB’s AC 800M or similar distributed control systems, it plays a critical role in the system architecture as an interface between analog/digital sensors and the factory’s central control network.

This module natively supports protocols such as Modbus RTU, Profibus DP, and OPC UA, allowing devices from multiple vendors to operate as a unified ecosystem. The ABB IMCAM07B0000 is designed with a plug-and-play approach, reducing debugging time compared to customized solutions. Whether it’s renovating old production lines or deploying new automation projects, the ABB IMCAM07B0000 can simplify system design and improve reliability.

Core Advantages and Technical Highlights

Excellent Performance: Equipped with a dual-core processor, the ABB IMCAM07B0000 can process up to 10,000 I/O signals per second with a latency of less than milliseconds, ensuring real-time response in high-speed packaging lines or batch processing systems. Its built-in error correction algorithm reduces the risk of data corruption by 99.7%, which is crucial for applications where measurement defects may lead to production losses or safety accidents.

Robust Industrial Design: The module features an IP67 protection level aluminum shell, which is dustproof, waterproof, and resistant to mechanical impact (up to 50g), making it suitable for harsh environments such as foundries or outdoor substations. The wide temperature range (-40°C to 85°C) does not require an auxiliary cooling system, reducing installation costs. Its compact external dimensions (120 mm x 80 mm x 50 mm) facilitate dense installation in control cabinets, optimizing space utilization.

Future-Oriented Connectivity: Equipped with dual Ethernet ports and optional wireless (Wi-Fi 6/5G) expansion, the ABB IMCAM07B0000 supports edge computing functions, such as local data preprocessing before transmission to the cloud. This reduces reliance on centralized servers and lowers latency for time-sensitive applications such as predictive maintenance. The module also features secure boot and encrypted data transmission (AES-256) capabilities, addressing growing network security concerns in industrial systems.

Long-Term Reliability: Thermal simulation testing ensures that the internal temperature of the module remains below 50°C at full load, extending the lifespan of the components to over 10 years. The redundant power input (24 VDC/110 VAC) and hot-swappable design allow for maintenance without interrupting the system, meeting the goal of zero downtime manufacturing.

ABB IMCAM07B0000

Typical Application Scenarios

The ABB IMCAM07B0000 module is a key driver of precision monitoring and control, suitable for high-risk environments. In oil and gas refineries, this robust module is used to manage complex chemical processes, requiring real-time analysis of data from pressure sensors, flow meters, and temperature probes, and immediate action to prevent safety hazards and optimize production efficiency. It can withstand extreme temperatures, corrosive environments, and high vibrations, making it an ideal choice for upstream drilling operations and downstream refining units.

In the electronics manufacturing industry, the ABB IMCAM07B0000 ensures micrometer-level precision in component placement and quality control. For example, in semiconductor manufacturing facilities, this module works in conjunction with a vision system to detect micrometer-level defects on circuit boards and trigger immediate adjustments to the speed of robotic arms or conveyor belts. This response speed reduces material waste that can cost thousands of dollars per wafer, while maintaining strict compliance with ISO cleanroom standards.

In addition to discrete manufacturing, the ABB IMCAM07B0000 also performs well in process industries such as pulp and paper, with real-time adjustment of continuous raw material flow and monitoring of equipment health. By integrating with predictive maintenance systems, it can identify early signs of equipment wear (such as abnormal motor currents or bearing temperatures), enabling factory managers to proactively arrange repairs and avoid high unplanned downtime costs.

Related Model Recommendations

-

ABB IMCAM05B0000: Reduced I/O channels, suitable for small systems.

-

ABB IMCAM07B0001: Built-in GPS timestamp function, suitable for assets with wide geographical distribution.

-

ABB IMAI08B0000: Analog Input Module (8 channels, 16-bit resolution), used for sensor integration.

-

ABB IMDO16B0000: Digital output module (16 channels, 24 VDC), used for actuator control.

-

ABB IMGW01B0000: Gateway module, used for protocol conversion between Profinet and EtherCAT networks.

-

ABB IMPS02B0000: Redundant power supply unit (24 VDC, 5 A), suitable for critical task settings.

-

ABB IMSC03B0000: Security Expansion Module with Hardware Encryption Function.

Installation, Commissioning, and Maintenance Instructions

Installation Preparation: Ensure that the installation guide rail or panel can withstand a distributed weight of 1 kilogram (module + connecting cable). Maintain a minimum distance of 10 centimeters between power and signal lines to reduce electromagnetic interference (EMI) in high voltage environments. Verify network configuration (IP address, subnet mask) before powering on to avoid conflicts with existing networks.

Maintenance Suggestions: Conduct visual inspections every quarter to check for loose connectors or signs of corrosion on wiring terminals. Use manufacturer-provided software to update firmware every six months, typically including protocol enhancements and security patches. In harsh environments, clean the exterior of the chassis annually with non-abrasive solvents to prevent dust from affecting heat dissipation performance.

Service and Guarantee Commitment

ABB provides comprehensive support for the ABB IMCAM07B0000. The module comes with a robust warranty, ensuring quality and reliability. ABB offers extensive after-sales services, including technical support, repair services, and spare part supply. Customers can rely on ABB’s global network of service centers for prompt assistance and expert guidance. This commitment underscores ABB’s dedication to customer satisfaction and product excellence.