Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

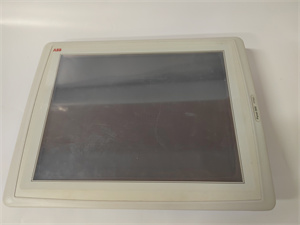

| Product Model | PP885R 3BSE069296R1 |

| Manufacturer | ABB |

| Product Category | 19-inch TFT Industrial HMI Operator Panel |

| Display Specifications | 19-inch TFT-LCD, 1280×1024 resolution, 16.7 million colors |

| Front Panel Protection | IP66 |

| Rear Panel Protection | IP20 |

| Touch Screen | Projected capacitive, 10-point multi-touch, 5 million operations |

| Housing Material | Front: Aluminum alloy; Rear: Powder-coated steel |

| Dimensions (W×H×D) | 483mm×383mm×85mm |

| Weight | Approximately 6.2kg |

| Processing Power | 1.6GHz dual-core processor, 2GB RAM |

| Storage | 32GB SSD, expandable via SD card (up to 32GB) |

| Communication Interfaces | 2×Ethernet (Gigabit), 2×USB 2.0, 1×USB 3.0, RS485/RS232 |

| Power Supply | 24V DC (18-30V DC), typical consumption 3.5A |

| Operating Temperature | 0°C to 50°C |

| Storage Temperature | -20°C to 70°C |

| Relative Humidity | 5-95% (non-condensing) |

| Certifications | CE, UL 508, ATEX Zone 2, IEC 61010 |

| Vibration Resistance | 10-500Hz, 1g acceleration |

ABB PP865 3BSE042236R1

ABB PP865 3BSE042236R1

Product Introduction

ABB PP885R 3BSE069296R1 is a high-performance 19-inch industrial HMI operator panel, designed to serve as a central interface for complex industrial automation systems. As an advanced member of ABB’s Panel 800 series, it builds on the capabilities of models like the PP865 3BSE042236R1 with enhanced processing power and a larger display.

This HMI provides operators with a superior visual and interactive experience, enabling efficient monitoring and control of large-scale industrial processes. The 19-inch high-resolution display ensures clear visualization of multiple process variables simultaneously, while the multi-touch interface simplifies navigation through complex menus. Whether integrated into manufacturing execution systems or energy management platforms, PP885R 3BSE069296R1 facilitates seamless interaction between operators and automated systems, improving decision-making speed and operational efficiency.

Core Advantages and Technical Highlights

Enhanced visual clarity:

The 19-inch 1280×1024 display with 16.7 million colors delivers exceptional image quality, surpassing the PP865 3BSE042236R1‘s 64k color range. In automotive assembly plants, this allows operators to monitor up to 12 concurrent production lines on a single screen, with color-coded status indicators that are instantly distinguishable—critical for identifying bottlenecks in real time.

Multi-touch functionality:

Unlike the resistive single-touch of the PP865 3BSE042236R1, the projected capacitive 10-point touch screen supports gestures like pinch-to-zoom and swipe. In oil refinery control rooms, operators can simultaneously adjust multiple process parameters by dragging sliders with two fingers, reducing interaction time by up to 40% compared to traditional interfaces.

Powerful processing capabilities:

The 1.6GHz dual-core processor and 2GB RAM enable smooth operation of complex HMI applications, including 3D process visualizations and real-time data trending. This processing power allows PP885R 3BSE069296R1 to handle up to 5000 tags simultaneously—three times more than the PP865 3BSE042236R1—making it ideal for large-scale facilities like chemical plants with extensive sensor networks.

Rugged design for harsh environments:

With an aluminum alloy front panel and IP66 protection, PP885R 3BSE069296R1 withstands harsh industrial conditions, including washdowns in food processing facilities and dust in mining operations. Its vibration resistance ensures reliable performance in mobile applications like shipboard control systems, where stability is critical for continuous operation.

Typical Application Scenarios

In large-scale pharmaceutical production facilities, ABB PP885R 3BSE069296R1 serves as the primary interface for monitoring batch processes across multiple reactors. Operators use the multi-touch screen to compare real-time temperature profiles against historical data, ensuring compliance with FDA regulations. The high-resolution display clearly shows 3D renderings of mixing patterns, helping identify potential uniformity issues that could affect product quality.

Within power generation plants, this HMI integrates with SCADA systems to provide a consolidated view of turbine performance, grid connections, and auxiliary systems. The 19-inch screen displays energy output graphs, equipment status indicators, and maintenance alerts simultaneously, enabling operators to respond quickly to fluctuations in demand or emerging faults—an improvement over the PP865 3BSE042236R1‘s smaller display when managing complex energy systems.

In automotive manufacturing, PP885R 3BSE069296R1 controls robotic assembly lines, with the multi-touch interface allowing technicians to program path adjustments directly on the screen. The Gigabit Ethernet ensures fast data exchange with PLCs, reducing latency when coordinating actions between welding robots, conveyors, and quality inspection systems.

Related Model Recommendations

- PP865 3BSE042236R1: A 15-inch predecessor with similar functionality but smaller display, suitable for space-constrained applications where the 19-inch size of PP885R 3BSE069296R1is unnecessary.

- PP880 3BSE042237R1: An intermediate 17-inch model between PP865and PP885R, offering a balance of size and performance for medium-scale processes.

- AC500 PLCs: ABB’s programmable controllers that integrate seamlessly with PP885R 3BSE069296R1, forming a complete control and visualization system.

- Panel Builder 800 Software: ABB’s HMI configuration tool optimized for PP885R 3BSE069296R1, enabling custom interface design with drag-and-drop functionality.

- PP885R-EXT: Expansion module for PP885R 3BSE069296R1adding additional serial ports and digital I/O, ideal for connecting legacy equipment.

- CP600 Series HMIs: Compact alternatives to PP885Rfor small-scale machines where advanced multi-touch features are not required.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing ABB PP885R 3BSE069296R1, ensure the mounting location can support its 6.2kg weight and provides adequate ventilation. Use M6 screws and a torque wrench (2.5-3Nm) for secure mounting. Verify the 24V DC power supply is stable within 18-30V, and connect the protective earth terminal to a grounded busbar. The panel should be positioned at eye level for operators, with at least 100mm clearance around it for cooling. Avoid direct sunlight to prevent display glare and overheating.

Maintenance suggestions: Clean the touch screen of PP885R 3BSE069296R1 with a microfiber cloth and isopropyl alcohol (50%) to remove oils and debris without damaging the capacitive layer. Inspect Ethernet and USB connections monthly for corrosion, especially in humid environments. Back up configuration data quarterly to the SD card to prevent loss during software updates. Replace the internal backup battery every 5 years (use ABB part 3BSE008549R1) to maintain real-time clock accuracy. If touch responsiveness decreases, recalibrate via the system menu rather than using external tools.

Service and Guarantee Commitment

ABB provides a 3-year warranty for PP885R 3BSE069296R1, covering defects in materials and workmanship. Our global technical support network offers 24/7 assistance for installation, configuration, and troubleshooting, with response times under 4 hours for critical issues.

We offer on-site commissioning services to ensure optimal integration with existing systems, plus training programs on Panel Builder 800 software. For mission-critical applications, ABB provides a spare parts delivery service guaranteeing replacement units within 48 hours. All repairs are performed by certified technicians using genuine components, ensuring PP885R 3BSE069296R1 maintains its original performance specifications throughout its operational life.