Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

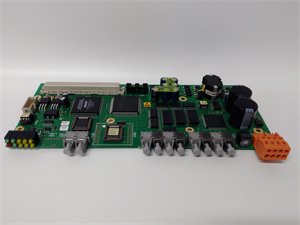

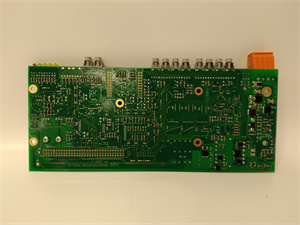

| Product Model | PPC905AE101 3BHE014070R0101 |

| Manufacturer | ABB |

| Product Category | Advanced Industrial Process Controller |

| Processor | 32-bit RISC processor, 800MHz |

| Memory | 256MB RAM, 512MB Flash (expandable to 1GB) |

| Operating System | Enhanced embedded real-time OS |

| I/O Interfaces | 16×analog inputs (4-20mA), 8×analog outputs (4-20mA), 32×digital inputs, 32×digital outputs |

| Communication Ports | 2×Gigabit Ethernet, 4×RS485, 2×USB 2.0, 1×SD card slot |

| Display | 7-inch color TFT LCD, 800×480 resolution |

| Operating Temperature | -20°C to 65°C |

| Power Supply | 24V DC (18-30V DC), typical current 1.2A |

| Dimensions (W×H×D) | 180mm×150mm×110mm |

| Weight | Approximately 1.8kg |

| Protection Rating | IP20 (enclosure), IP66 (front panel) |

| Certifications | CE, UL 508, IEC 61131-2, ATEX Zone 2 |

PPC905AE101 3BHE014070R0101

Product Introduction

ABB PPC905AE101 3BHE014070R0101 is a high-performance industrial process controller designed for medium to large-scale industrial processes requiring enhanced I/O capacity and processing power. As an upgraded model from the PPC902AE101 3BHE010751R0101, it retains the compact form factor while doubling key specifications to handle more complex control tasks.

Part of ABB’s advanced control series, PPC905AE101 3BHE014070R0101 excels in multi-loop control scenarios such as batch processing, complex material handling, and integrated production lines. Its enhanced real-time OS delivers deterministic performance with control cycle times as low as 5ms, outperforming the PPC902AE101 3BHE010751R0101 in time-critical applications where precision and speed are paramount.

Core Advantages and Technical Highlights

Superior processing power:

With an 800MHz processor (double the speed of PPC902AE101 3BHE010751R0101), this controller handles up to 64 concurrent control loops without performance degradation. In pharmaceutical batch reactors, PPC905AE101 3BHE014070R0101 simultaneously regulates temperature, pressure, pH, and agitator speed with cross-loop coordination, ensuring consistent batch quality that basic controllers can’t achieve.

Expanded I/O capacity:

Featuring 16 analog inputs (twice that of PPC902AE101 3BHE010751R0101) and 64 digital I/Os, it eliminates the need for expansion modules in most mid-sized systems. In a food processing line, this allows direct connection to 12 temperature sensors, 4 flow meters, and 32 actuators—all without additional hardware, reducing system complexity by 40%.

Enhanced connectivity and visualization:

The 7-inch color display (upgraded from the monochrome screen of PPC902AE101 3BHE010751R0101) provides intuitive process visualization, while Gigabit Ethernet enables faster data exchange with SCADA systems. In solar power plants, operators can monitor inverter performance metrics in real time via the color interface, with data transmitted to central systems 10x faster than via the PPC902AE101‘s 100BASE-T ports.

Extreme environment resilience:

Operating from -20°C to 65°C (wider than PPC902AE101 3BHE010751R0101‘s range), this controller thrives in arctic oil fields or desert solar farms. Its IP66 front panel withstands high-pressure washdowns, making it suitable for hygienic environments like dairy processing facilities where frequent cleaning is mandatory.

PPC905AE101 3BHE014070R0101

Typical Application Scenarios

In water treatment plants, ABB PPC905AE101 3BHE014070R0101 manages multi-stage filtration systems, controlling 12 pH adjustment points, 8 chemical dosing pumps, and 16 valve actuators simultaneously. The color display shows real-time trends of turbidity, chlorine levels, and flow rates—an upgrade over the PPC902AE101 3BHE010751R0101‘s monochrome interface—enabling operators to detect anomalies at a glance.

Within semiconductor fabrication cleanrooms, this controller regulates environmental conditions across multiple zones, maintaining precise temperature (±0.1°C) and humidity (±1%) levels. Its enhanced processing power handles complex PID tuning algorithms that compensate for cross-zone interference, a task beyond the PPC902AE101‘s capabilities in large facilities.

In modular chemical plants, PPC905AE101 3BHE014070R0101 coordinates batch production across 8 reactors, synchronizing material transfers and reaction timings via Gigabit Ethernet. The expanded I/O connects directly to 16 pressure transmitters and 8 mass flow controllers, eliminating the need for remote I/O racks required when using the PPC902AE101 in similar setups.

Related Model Recommendations

- PPC902AE101 3BHE010751R0101: Lower I/O variant of PPC905AE101 3BHE014070R0101for smaller systems, offering cost savings when full capacity isn’t needed.

- PPC907AE101 3BHE014071R0101: Higher-end model with 1GHz processor and 100 digital I/Os, ideal for scaling beyond PPC905AE101‘s capabilities.

- PP885R 3BSE069296R1: 19-inch HMI that pairs with PPC905AE101 3BHE014070R0101for advanced visualization in control rooms.

- AC500 PLCs: Integrate with PPC905AE101 3BHE014070R0101to expand into large-scale distributed control systems.

- CI858K 3BSE032493R1: 5G communication module for PPC905AE101 3BHE014070R0101, enabling remote monitoring in remote locations.

- PPC905-EXT 3BHE014072R0001: Expansion unit adding 8 analog outputs to PPC905AE101 3BHE014070R0101for specialized applications.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing ABB PPC905AE101 3BHE014070R0101, ensure the DIN rail is rated for at least 3kg to support the 1.8kg weight. Use M4 screws with 2-2.5Nm torque for secure mounting. Connect to a 24V DC power supply with surge protection (18-30V), and allow 70mm clearance above/below for ventilation. For Gigabit Ethernet, use shielded Cat6 cables with proper grounding to prevent EMI interference with analog inputs.

Maintenance suggestions: Inspect terminal blocks of PPC905AE101 3BHE014070R0101 quarterly, tightening to 0.8Nm if loose—critical in high-vibration environments like pumping stations. Clean the color display with a microfiber cloth and 30% isopropyl alcohol to avoid scratch damage. Backup configurations weekly to the SD card, and update firmware semi-annually via ABB’s Control Builder software. If analog inputs drift, perform calibration using the built-in routine (requires standard signal generator) rather than external tools.

Service and Guarantee Commitment

ABB provides a 5-year warranty for PPC905AE101 3BHE014070R0101, matching the reliability commitment of the PPC902AE101 while extending support for advanced features. Our technical support team offers 8-hour response times for critical issues, with specialized engineers trained in multi-loop control applications.

Factory repairs use genuine components to maintain original performance specifications. For mission-critical systems, we offer 24-hour on-site service in major industrial regions. ABB’s training programs include advanced courses on distributed control strategies specific to PPC905AE101 3BHE014070R0101, ensuring customers fully leverage its expanded capabilities for optimal process efficiency.