Description

| Parameter name | Parameter value |

| Product model | PPC905AE101 3BHE014070R0101 |

| Manufacturer | ABB |

| Product category | Process control module for industrial automation |

| Processing power | 32-bit RISC processor, 200 MHz |

| Memory capacity | 128 MB RAM; 512 MB flash memory |

| I/O interfaces | 8 analog inputs (4-20 mA); 4 analog outputs (4-20 mA); 16 digital inputs (24 VDC); 8 digital outputs (24 VDC, 2 A) |

| Communication protocols | Ethernet/IP, Modbus TCP/IP, Profibus DP |

| Power supply | 24 VDC ±10%, 1.5 A max |

| Operating temperature | -20°C to +60°C |

| Dimensions (WxHxD) | 160 mm x 100 mm x 80 mm |

| Protection class | IP20 |

| Certifications | IEC 61131-2, CE, UL 508 |

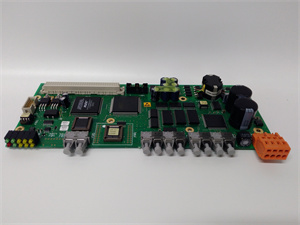

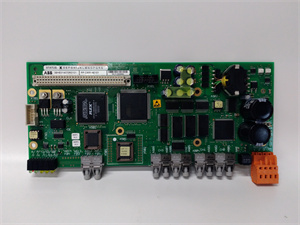

ABB PPC905AE101 3BHE014070R0101

Product introduction

The PPC905AE101 3BHE014070R0101 is a high-performance process control module from ABB, designed to handle complex industrial automation tasks. As part of ABB’s Advant OCS system, it serves as a critical link between sensors, actuators, and higher-level control systems.

This module excels in real-time data processing and control logic execution, making it ideal for regulating continuous processes. With its 32-bit RISC processor and ample memory, the PPC905AE101 3BHE014070R0101 can run sophisticated control algorithms while managing multiple I/O signals simultaneously. Whether in chemical processing, water treatment, or food production, it ensures precise control over variables like temperature, pressure, and flow, directly contributing to improved product quality and process efficiency.

Core advantages and technical highlights

Fast processing capabilities: The 200 MHz 32-bit RISC processor of the PPC905AE101 3BHE014070R0101 enables rapid execution of control logic. In a wastewater treatment plant, it processes data from 8 pH sensors and adjusts chemical dosing pumps via analog outputs in under 50 ms, maintaining pH levels within ±0.1 units—critical for regulatory compliance.

Versatile I/O handling: With 8 analog inputs, 4 analog outputs, 16 digital inputs, and 8 digital outputs, the PPC905AE101 3BHE014070R0101 connects seamlessly to diverse field devices. A food and beverage plant uses it to monitor temperature (analog inputs) and conveyor status (digital inputs), while controlling valves (analog outputs) and motors (digital outputs) in a bottling line, streamlining operations into a single control point.

Multi-protocol communication: Supporting Ethernet/IP, Modbus TCP/IP, and Profibus DP, the PPC905AE101 3BHE014070R0101 integrates effortlessly into mixed-network environments. A pharmaceutical facility leveraged its Ethernet/IP interface to connect to a SCADA system for centralized monitoring, while using Profibus DP to communicate with legacy motor drives, avoiding costly network upgrades.

Wide temperature tolerance: Operating from -20°C to +60°C, the PPC905AE101 3BHE014070R0101 thrives in harsh conditions. In a desert-based solar power plant, it reliably controls coolant flow despite extreme temperature swings, ensuring consistent panel efficiency.

Typical application scenarios

Chemical processing: In a batch chemical reactor, the PPC905AE101 3BHE014070R0101 regulates temperature, pressure, and reagent flow. It receives analog input signals from thermocouples and pressure transducers, executes PID control loops, and adjusts heating elements and control valves via analog outputs. Digital inputs monitor valve positions, while digital outputs trigger alarms and shutdowns if parameters exceed safe limits. This precise control reduces batch variation by 12% compared to older systems.

Water treatment: A municipal water treatment plant uses the PPC905AE101 3BHE014070R0101 to manage filtration and disinfection processes. It monitors turbidity (4-20 mA input) and chlorine levels, adjusting filter backwash cycles and chemical injection rates. Modbus TCP/IP communication links it to a central HMI, allowing operators to set treatment parameters remotely. The module’s robust design ensures uninterrupted operation, even during power fluctuations common in rural areas.

Food processing: In a dairy plant, the PPC905AE101 3BHE014070R0101 controls pasteurization temperatures. It receives real-time temperature data from RTD sensors, maintains the s

ABB PPC905AE101 3BHE014070R0101

etpoint via heating elements, and triggers conveyor belt stops (digital outputs) if temperatures fall outside the 72-75°C range. Its fast response time prevents under-pasteurization, ensuring food safety while minimizing energy waste.

Related model recommendations

PPC902AE101: A compact 2-channel variant of the PPC905AE101 3BHE014070R0101, suitable for simple control tasks like small-scale pumping systems.

PPC910AE101: Expanded version with 16 analog inputs, ideal for large-scale processes requiring more sensor inputs than the PPC905AE101.

CI854A: Communication module that enhances the PPC905AE101’s protocol support, adding IEC 60870-5-104 for utility applications.

AI810: Analog input extension module, pairs with PPC905AE101 to add 8 more 4-20 mA inputs for complex sensor networks.

DO820: Digital output module, increases the PPC905AE101’s switching capacity for controlling larger motors and valves.

PM864K01: ABB PLC that integrates with PPC905AE101 3BHE014070R0101 for distributed control systems requiring coordinated multi-module operation.

HMI600: Touchscreen interface displaying real-time data from the PPC905AE101, enabling local parameter adjustments.

Installation, commissioning and maintenance instructions

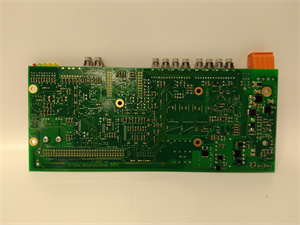

Installation preparation: Mount PPC905AE101 3BHE014070R0101 on a 35mm DIN rail in a control cabinet, ensuring 50mm clearance for cooling. Use shielded cables for analog signals (0.5mm²) and twisted-pair for digital I/O. Connect power with 24 VDC, verifying polarity to avoid damage. Check that the operating environment is free from excessive vibration and moisture, as per its IP20 rating.

Maintenance suggestions: Inspect monthly for loose terminals and dust—clean with compressed air. Quarterly, verify analog input accuracy using a signal generator, checking for drift beyond ±0.2% of full scale. Update firmware annually via ABB’s Control Builder software to access new features. Replace the backup battery (3HAC031682-001) every 5 years to preserve configuration data during power loss. For communication issues, test Ethernet/IP connectivity with a network tester and reconfigure if necessary.

Service and guarantee commitment

ABB provides a 3-year warranty for the PPC905AE101 3BHE014070R0101, covering manufacturing defects. During this period, ABB offers free replacement of faulty modules and 24/7 technical support, with average response times under 3 hours.

Customers gain access to online resources, including user manuals, firmware updates, and application notes. Optional services include on-site commissioning and training sessions tailored to specific industries. ABB guarantees spare parts availability for 10 years post-production, ensuring long-term support. This commitment reflects confidence in the module’s reliability and dedication to minimizing downtime in critical automation processes.