Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | REF543KM129AAAB |

| Manufacturer | ABB |

| Product category | Medium-voltage feeder protection and control terminal |

| Rated voltage | 3AC 50/60Hz, 6kV – 36kV |

| Rated current | 5A – 6300A (via current transformers) |

| Communication protocols | IEC 61850, Modbus RTU/TCP, DNP3, IEC 60870-5-103, Profibus DP |

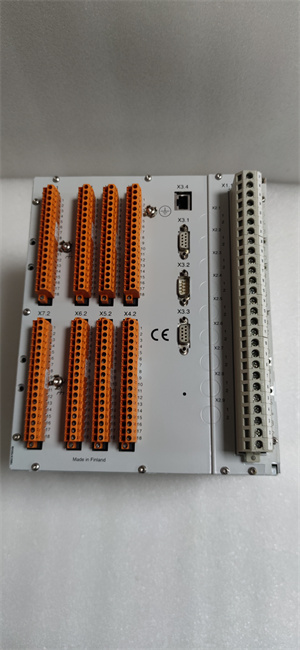

| Digital inputs | 20 binary inputs (optically isolated) |

| Digital outputs | 16 output relays (5A, 250V AC) |

| Protection functions | Overcurrent (phase/ground), directional overcurrent, distance protection, over/under voltage, frequency protection, breaker failure, auto-reclosing |

| Measurement accuracy | Class 0.2 for current/voltage; Class 0.5 for power |

| Operating temperature | -40°C to +70°C |

| Protection class | IP40 (front panel); IP54 (with optional enclosure) |

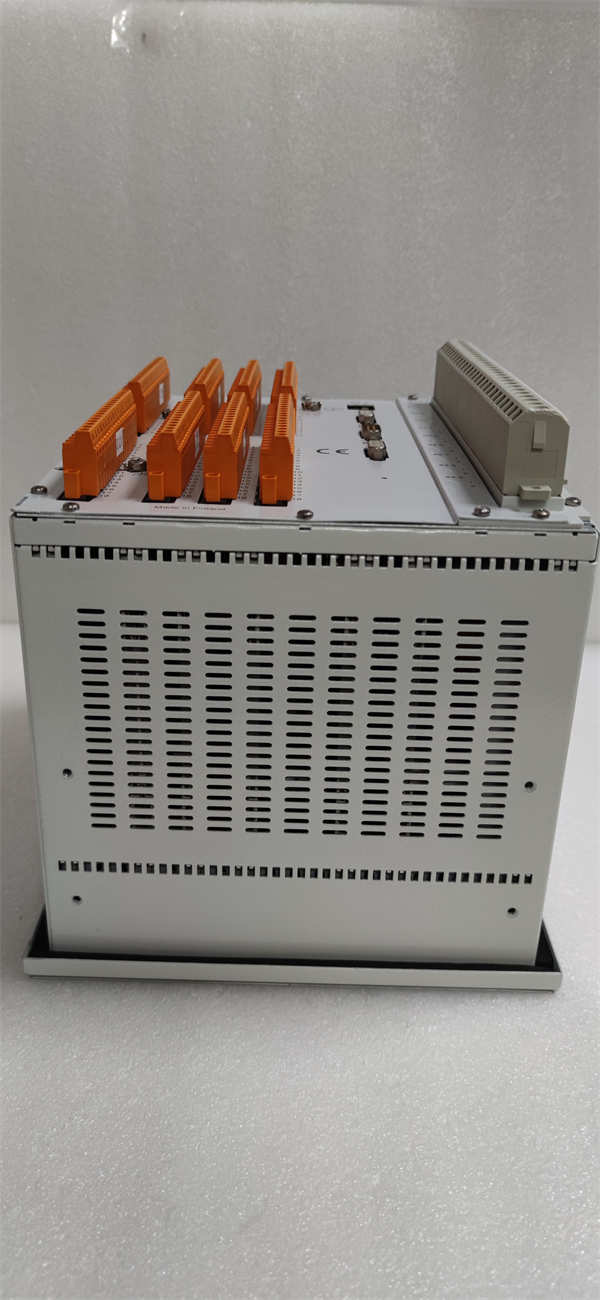

| Dimensions (WxHxD) | 280mm x 360mm x 180mm |

| Weight | 8.5kg |

| Certifications | IEC 61850-3, IEC 60255, UL 508, CE, ATEX |

ABB REF543KM129AAAB

Product introduction

The ABB REF543KM129AAAB is an advanced medium-voltage feeder protection and control terminal, part of ABB’s REF540 series—renowned for reliability in power distribution networks. Designed to safeguard 6kV – 36kV feeders, it integrates protection, measurement, control, and communication into a single device, serving as a critical component in smart grids and industrial substations.

This terminal combines robust protection algorithms with precise monitoring capabilities. The REF543KM129AAAB detects and isolates faults (such as short circuits or overloads) within milliseconds, minimizing downtime. Its compatibility with IEC 61850 ensures seamless integration into digital substations, enabling remote monitoring and control via SCADA systems. Whether in utility networks or industrial plants, it enhances grid stability while reducing operational costs through automated control features.

Core advantages and technical highlights

Advanced protection suite: Equipped with directional overcurrent and distance protection, the REF543KM129AAAB accurately identifies fault locations in complex networks. A 13kV industrial substation reported a 40% reduction in fault clearance time after upgrading to this terminal, limiting equipment damage during short circuits. Its adaptive auto-reclosing logic (with configurable dead time) optimizes restoration in overhead line networks, reducing outage duration by 30% in a rural utility application.

High-precision measurement: With Class 0.2 accuracy for current/voltage and Class 0.5 for power, the REF543KM129AAAB provides revenue-grade metering data. A municipal power utility uses it to monitor energy flows between feeders, enabling accurate billing and load balancing. The terminal’s power quality monitoring (THD, voltage sags/swells) helps identify harmonic issues—critical for industrial customers with sensitive equipment.

Digital substation readiness: Native IEC 61850 compliance (including GOOSE and Sampled Values) allows the REF543KM129AAAB to operate in fully digital environments. A smart grid project replaced traditional hardwired connections with this terminal, reducing cabling by 60% and simplifying substation expansion. Its time-synchronized measurements (IEEE 1588 PTP) enable precise fault location across distributed networks.

Rugged design: Certified to operate in -40°C to +70°C, the REF543KM129AAAB withstands extreme conditions. A mining operation in Siberia deployed it in outdoor substations, where it reliably functioned despite temperature swings of 60°C daily. The IP54-rated enclosure (optional) protects against dust and water ingress, making it suitable for coastal or industrial environments.

Typical application scenarios

Utility distribution networks: In a 20kV urban feeder network, the REF543KM129AAAB protects 12 feeders supplying residential and commercial areas. It uses directional overcurrent protection to isolate faults in specific segments, ensuring only 5% of customers are affected during outages. Its DNP3 communication links to the utility’s SCADA, enabling remote recloser control and load shedding during peak demand.

Industrial plants: A petrochemical facility uses the REF543KM129AAAB to protect 11kV feeders powering critical compressors and pumps. The terminal’s breaker failure protection triggers backup breakers within 50ms, preventing cascading failures. Its under/over voltage protection safeguards sensitive PLC systems from voltage fluctuations, reducing unplanned downtime by 25%.

Renewable energy integration: A 50MW solar farm connects to the grid via a 33kV feeder protected by the REF543KM129AAAB. It monitors frequency and voltage fluctuations caused by cloud cover, sending signals to the farm’s inverter control system to maintain grid compliance. The terminal’s IEC 61850 interface enables real-time data sharing with the transmission system operator, facilitating smooth renewable energy integration.

ABB REF543KM129AAAB

Related model recommendations

REF541KM118AAAA: Entry-level variant for 6kV – 17.5kV feeders, with basic protection functions—ideal for small industrial plants.

REF545KM130AAAC: High-end model with advanced distance protection and synchrocheck, suitable for 36kV – 72.5kV transmission lines.

REF543KM127AAAB: Similar to REF543KM129AAAB but with reduced I/O—cost-effective for less complex feeders.

CMU800: Communication module adding 5G connectivity to REF543KM129AAAB for remote substations with limited fiber access.

HMI500: 10-inch touchscreen panel for local control/monitoring of REF543KM129AAAB, displaying real-time waveforms and event logs.

PTC510: Test kit for verifying protection functions of REF543KM129AAAB during commissioning, ensuring compliance with grid codes.

RET670: ABB’s transformer protection relay, often paired with REF543KM129AAAB in substation automation systems.

Installation, commissioning and maintenance instructions

Installation preparation: Mount REF543KM129AAAB in a control cabinet with ambient temperature -40°C to +70°C, ensuring 100mm clearance for ventilation. Connect current transformers (CTs) and voltage transformers (VTs) to dedicated terminals, verifying polarity to avoid protection misoperation. Use shielded twisted-pair cables for communication (IEC 61850) and power (24V DC), grounding shields at both ends. Torque terminal screws to 1.2 Nm and perform insulation resistance tests (≥100MΩ at 500V DC) before power-up.

Maintenance suggestions: Inspect quarterly for dust buildup—clean with compressed air (max 6 bar). Test protection functions annually using the PTC510 kit, verifying trip times for overcurrent and voltage faults. Check communication links (IEC 61850 GOOSE) for latency <10ms. Replace relay outputs every 100,000 operations or 10 years, using ABB genuine parts (part no. 3HAC064921-001). Backup configuration data monthly to a secure server to facilitate quick recovery after firmware updates.

Service and guarantee commitment

ABB offers a 5-year warranty for REF543KM129AAAB, covering manufacturing defects and performance issues. During this period, ABB provides 24/7 technical support via its global network, with on-site assistance available within 48 hours for critical faults.

Customers receive lifetime access to firmware updates, protection setting guides, and IEC 61850 configuration tools via ABB’s Power Portal. Optional services include factory acceptance testing (FAT), on-site commissioning with relay coordination, and operator training. ABB guarantees spare parts availability for 20 years post-production, ensuring long-term reliability for critical power infrastructure. This commitment reflects confidence in the terminal’s durability and dedication to grid resilience.