Description

Detailed parameter table

| Parameter name | Parameter value |

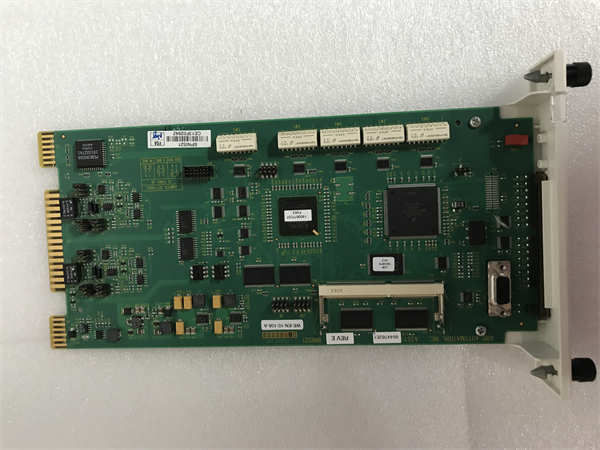

| Product model | SPNPM22 |

| Manufacturer | ABB |

| Product category | Power quality monitoring and analysis device (assumed based on ABB’s product portfolio) |

| Voltage measurement range | 100 – 690 V AC (for three-phase systems), configurable for single – phase measurements as well |

| Current measurement range | 0 – 5 A (direct input), expandable to higher ranges using external current transformers (CTs) |

| Frequency measurement range | 45 – 65 Hz |

| Harmonic analysis | Up to 50th harmonic for both voltage and current, with accurate THD (Total Harmonic Distortion) calculation |

| Power measurement accuracy | Class 0.5 for active power, Class 1 for reactive and apparent power |

| Communication interfaces | Ethernet (Modbus TCP), RS485 (Modbus RTU), optional wireless communication (Wi-Fi or cellular) |

| Data storage capacity | 16GB internal flash memory, expandable via external SD card (up to 128GB) |

| Digital inputs/outputs | 4 digital inputs (optically isolated), 2 digital outputs (relay contacts, 5A, 250V AC) |

| Operating temperature | -20°C to +60°C |

| Protection class | IP30 (for indoor use), with optional enclosures available for harsher environments |

| Dimensions (WxHxD) | 120mm x 200mm x 80mm |

| Weight | 1.2 kg |

| Certifications | IEC 61000 – 4 series for EMC compliance, CE |

ABB SPNPM22

Product introduction

The ABB SPNPM22 is a sophisticated power quality monitoring and analysis device, designed to play a crucial role in ensuring the reliable operation of electrical systems. As industries increasingly rely on stable power supplies to safeguard sensitive equipment and optimize energy consumption, the SPNPM22 steps in as a comprehensive solution.

This device is engineered to continuously monitor key electrical parameters, detect anomalies, and provide detailed reports on power quality issues. By integrating seamlessly into existing electrical networks, it enables facility managers, energy engineers, and system operators to proactively manage power – related problems, reducing the risk of equipment failures, production losses, and unexpected downtime. Whether in industrial plants, commercial buildings, or utility substations, the SPNPM22 serves as a vigilant guardian of power quality.

Core advantages and technical highlights

High – precision harmonic analysis: The SPNPM22’s ability to analyze up to the 50th harmonic in voltage and current signals is a significant advantage. In a data center, which is filled with non – linear loads such as servers and power supplies, the device accurately identified and reported high – level harmonics. By implementing corrective measures based on these reports, the data center was able to reduce equipment overheating by 30%, extending the lifespan of its IT infrastructure.

Accurate power measurement: With Class 0.5 accuracy for active power and Class 1 for reactive and apparent power, the SPNPM22 provides highly reliable metering data. A manufacturing plant used this device to precisely measure power consumption across different production lines. This led to the identification of energy – intensive processes, allowing the plant to implement energy – saving strategies and achieve a 15% reduction in monthly energy costs.

Flexible communication options: The availability of Ethernet (Modbus TCP) and RS485 (Modbus RTU) interfaces, along with the option for wireless communication, makes the SPNPM22 adaptable to various network setups. A remote wind farm, for example, utilized the optional cellular communication feature to transmit power quality data to a central monitoring station. This eliminated the need for costly wired connections and enabled real – time monitoring of power quality in a location with limited infrastructure.

Robust data storage and retrieval: Equipped with 16GB of internal flash memory, expandable up to 128GB via an external SD card, the SPNPM22 can store large volumes of historical data. A utility company used this data storage capacity to analyze long – term power quality trends in its distribution network. By studying historical data, the utility was able to predict and prevent potential power outages, improving overall grid reliability.

Typical application scenarios

Industrial manufacturing: In a large – scale automotive manufacturing plant, the SPNPM22 monitors power quality across multiple production areas, including robotic assembly lines, painting booths, and conveyor systems. The device detects voltage sags and swells that could potentially disrupt the operation of sensitive robotic equipment. By alerting plant engineers in real – time, the SPNPM22 helps prevent production stoppages, reducing costly downtime by 20%.

Commercial buildings: A high – rise office building uses the SPNPM22 to monitor power quality in its electrical distribution system. The device identifies harmonics generated by office equipment such as computers, printers, and elevators. By taking corrective actions, such as installing harmonic filters, the building management was able to improve the efficiency of its electrical system, resulting in a 10% reduction in energy consumption.

Renewable energy generation: At a solar power plant, the SPNPM22 monitors the power quality of the electricity being fed into the grid. It ensures that the voltage, frequency, and harmonics of the solar – generated power meet grid – connection requirements. In case of any deviations, the device can send signals to the plant’s control system to adjust the operation of the inverters, ensuring seamless integration of renewable energy into the grid.

ABB SPNPM22

Related model recommendations

SPNPM11: A more basic version of the SPNPM22, suitable for small – scale applications or where less complex power quality monitoring is required. It has a smaller data storage capacity and fewer digital inputs/outputs, making it cost – effective for small businesses or residential applications.

SPNPM33: A high – end model with advanced features such as real – time phasor measurement (PMU – like capabilities) and enhanced cybersecurity features. It is ideal for utility transmission and distribution systems, where precise phasor data is crucial for grid stability analysis and where protecting against cyber threats is of utmost importance.

EMAX2 Power Circuit Breaker: Often used in conjunction with the SPNPM22 in industrial and commercial electrical panels. The EMAX2 breaker provides reliable overcurrent and short – circuit protection, while the SPNPM22 monitors power quality. Together, they form a comprehensive solution for electrical system protection and monitoring.

REM615: ABB’s motor protection relay, which can be integrated with the SPNPM22 in industrial plants. The REM615 protects motors from various faults, and the SPNPM22 monitors the power quality of the supply to the motors. This combination helps ensure the reliable operation of motors, which are critical components in industrial processes.

SCADA software (ABB Ability System 800xA): Can be used to manage and visualize the data collected by the SPNPM22. The SCADA software provides a user – friendly interface for operators to monitor power quality in real – time, set alarms, and generate reports. It enables centralized control and management of power quality across multiple sites.

Installation, commissioning and maintenance instructions

Installation preparation: Mount the SPNPM22 in a suitable control panel or enclosure, ensuring proper ventilation and protection from dust and moisture. Connect the voltage and current inputs according to the device’s wiring diagram, using appropriate gauge wires. For current measurements above 5A, connect external current transformers (CTs) to the device. Verify the correct connection of communication cables (Ethernet or RS485) and configure the communication settings according to the network requirements.

Commissioning: Power up the SPNPM22 and use the provided software or web – based interface to configure the device settings, such as measurement ranges, communication protocols, and alarm thresholds. Calibrate the device using known reference signals to ensure accurate measurements. Test the communication links by sending and receiving data between the SPNPM22 and the connected monitoring system.

Maintenance suggestions: Periodically (every 6 months) check the physical connections of the device to ensure they are secure. Clean the device and its enclosure to remove dust buildup, which could affect its performance. Update the device’s firmware regularly to benefit from the latest features and bug fixes. Analyze the historical data stored in the device to identify any long – term trends or potential issues. In case of any abnormal behavior or error messages, refer to the device’s user manual or contact ABB’s technical support for assistance.

Service and guarantee commitment

ABB offers a 3 – year warranty for the SPNPM22, covering manufacturing defects and performance issues. During this period, ABB provides 24/7 technical support via its global network. Customers can reach out to ABB’s support team for installation guidance, troubleshooting, and software – related issues. ABB also offers on – site training for customers who want to learn how to use the SPNPM22 effectively.

In addition, ABB guarantees the availability of spare parts for the SPNPM22 for at least 10 years after the product’s production end. This ensures that customers can maintain the device’s functionality over its long lifespan. ABB’s commitment to service and support reflects its confidence in the quality and reliability of the SPNPM22, providing customers with peace of mind when using this power quality monitoring solution.