Description

Detailed parameter table

| Parameter name | Parameter value |

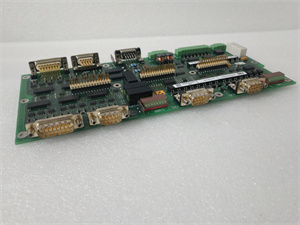

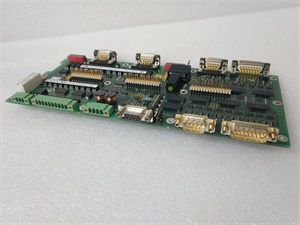

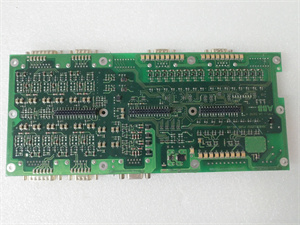

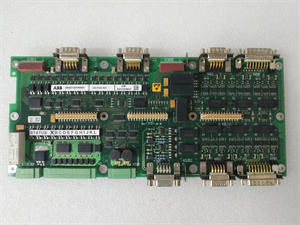

| Product model | UAD142A01 3BHE012551R0001 |

| Manufacturer | ABB |

| Product category | Analog input module (for industrial control systems) |

| Input channels | 8 isolated channels |

| Input signal type | 4-20mA, 0-20mA, 0-10V DC |

| Signal isolation | 2.5kVrms (channel-to-channel, channel-to-ground) |

| Resolution | 16-bit |

| Accuracy | ±0.05% of full scale (at 25°C) |

| Operating voltage | 24V DC ±10% |

| Power consumption | 3.2W (typical) |

| Operating temperature | -5°C to 55°C |

| Dimensions | 100mm × 160mm × 25mm |

| Mounting type | DIN rail (35mm) or backplane mounting |

| Communication interface | Compatible with ABB AC800M controller via PROFINET |

| Certifications | CE, UL, IEC 61131-2 |

ABB UAD142A01 3BHE012551R0001

Product introduction

The ABB UAD142A01 3BHE012551R0001 is a high-precision analog input module designed to integrate critical sensor data into industrial control systems, serving as a vital link between field devices and automation controllers. As a key component in ABB’s distributed control system (DCS) ecosystem, it excels in converting analog signals from sensors (such as pressure transducers, temperature probes, and flow meters) into digital data for processing by controllers like the AC800M.

This module’s 8 isolated channels ensure reliable signal acquisition even in electrically noisy environments, a common challenge in manufacturing plants, power stations, and chemical facilities. The UAD142A01 3BHE012551R0001 offers exceptional accuracy (±0.05% of full scale) and 16-bit resolution, making it ideal for applications where precise measurement of process variables directly impacts product quality, energy efficiency, and safety. Its compact design and flexible mounting options allow seamless integration into existing control cabinets, while compatibility with PROFINET ensures easy communication with higher-level control systems.

Core advantages and technical highlights

Superior signal integrity:

The UAD142A01 3BHE012551R0001 features 2.5kVrms isolation between channels and from channels to ground, eliminating cross-talk and interference from high-voltage equipment or motor drives. This isolation is critical in environments with heavy electrical noise, such as steel mills or pulp and paper plants, where even small signal distortions can lead to incorrect process control decisions. Unlike non-isolated modules, it maintains measurement accuracy regardless of ground potential differences between field devices and the control system.

Broad signal compatibility:

Supporting multiple input types (4-20mA, 0-20mA, 0-10V DC), the UAD142A01 3BHE012551R0001 adapts to diverse sensor technologies without requiring additional signal converters. This versatility simplifies system design, allowing engineers to connect pressure transducers (4-20mA), level sensors (0-10V), and flow meters (0-20mA) to the same module. The 16-bit resolution ensures that even small signal variations (e.g., a 0.1mA change in a 4-20mA loop) are captured, enabling early detection of process anomalies.

Seamless system integration:

Designed for ABB’s AC800M controller ecosystem, the UAD142A01 3BHE012551R0001 communicates via PROFINET, ensuring fast data transfer (up to 100Mbps) and easy configuration through ABB’s Control Builder M software. This integration eliminates the need for custom drivers or complex programming, reducing setup time. The module’s hot-swappable design allows replacement without powering down the entire system, minimizing downtime during maintenance—a critical advantage in continuous-process industries like oil refining.

ABB UAD142A01 3BHE012551R0001

Typical application scenarios

In a coal-fired power plant, the UAD142A01 3BHE012551R0001 monitors key parameters in the boiler system. It collects 4-20mA signals from pressure transducers measuring steam pressure, temperature transmitters tracking flue gas temperature, and flow meters monitoring water intake. The module’s isolation protects these signals from interference from nearby high-voltage transformers, ensuring the AC800M controller receives accurate data to adjust fuel feed and air flow, optimizing combustion efficiency and reducing emissions.

In a chemical processing plant, the UAD142A01 3BHE012551R0001 integrates with pH sensors, level transmitters, and pressure transducers in a batch reactor system. Each of its 8 channels is dedicated to a critical variable: reactor pressure, temperature, pH level, and feed flow rates. The module’s high accuracy ensures precise monitoring of pH (converted to 4-20mA) during chemical reactions, where even a 0.1 pH deviation can affect product quality. Data from the module is sent to the AC800M controller, which adjusts reagent dosing to maintain optimal conditions.

In a water treatment facility, the UAD142A01 3BHE012551R0001 processes signals from turbidity sensors, chlorine analyzers, and flow meters. It converts these analog signals into digital data for the control system, which uses the information to regulate filtration processes and chemical dosing. The module’s ability to operate in humid environments (within its temperature range) and resist electrical noise from pumps and motors ensures reliable performance in this demanding setting.

Related model recommendations

- UAD141A01: A 4-channel analog input module, serving as a smaller-scale alternative to the UAD142A01 3BHE012551R0001for applications requiring fewer inputs.

- UAO142A01: An analog output module by ABB, complementary to the UAD142A01 3BHE012551R0001. It converts digital control signals to 4-20mA outputs, ideal for controlling valves or pumps based on data from the input module.

- 3BHE032054R0101: ABB’s AC800M controller, which directly communicates with the UAD142A01 3BHE012551R0001via PROFINET to process analog data.

- UDD142A01: A digital input module from ABB, often used alongside the UAD142A01 3BHE012551R0001to monitor discrete signals (e.g., valve open/close status) in mixed-signal systems.

- UAD248A01: A high-density analog input module with 16 channels, suitable for large-scale applications where the UAD142A01 3BHE012551R0001’s 8 channels are insufficient.

- 3BSE018106R1: ABB’s PROFINET communication module, enhancing the UAD142A01 3BHE012551R0001’s connectivity in distributed control systems with multiple I/O nodes.

Installation, commissioning and maintenance instructions

Installation preparation:

Before installing the UAD142A01 3BHE012551R0001, ensure the control cabinet is clean, dry, and free from excessive vibration. Verify the 24V DC power supply is properly grounded and protected by a 1A fuse. Use a torque screwdriver to mount the module on a 35mm DIN rail or backplane, applying 0.5Nm torque to securing screws. When connecting field devices, use twisted-pair shielded cable for each channel, grounding the shield at the module end to minimize noise. Label all wiring clearly to avoid confusion during commissioning, and ensure channel isolation is maintained by separating high-voltage and low-voltage lines.

Maintenance suggestions:

For the UAD142A01 3BHE012551R0001, perform monthly visual inspections to check for loose connections, corrosion on terminals, or signs of overheating (discoloration). Clean the module’s surface with a dry, lint-free cloth to remove dust, which can impede heat dissipation. Calibrate the module annually using a precision signal generator, verifying accuracy across the full range of input signals (e.g., 4mA, 12mA, 20mA for current inputs). If a channel fails, isolate the issue by swapping sensors between channels to rule out field device problems. Replace faulty modules with ABB-approved spares to ensure compatibility and maintain system integrity.

Service and guarantee commitment

ABB provides a 2-year warranty for the UAD142A01 3BHE012551R0001, covering defects in materials and workmanship under normal operating conditions. Our global technical support team offers 24/7 assistance for installation, troubleshooting, and configuration, with experts available to help integrate the module into ABB or third-party control systems.

Customers receive access to comprehensive documentation, including user manuals, wiring diagrams, and calibration procedures, to facilitate smooth deployment. In the event of a failure, ABB ensures rapid replacement of critical components, with regional stock holding to minimize downtime. This commitment reflects our confidence in the UAD142A01 3BHE012551R0001’s reliability and our dedication to supporting customers throughout the product’s lifecycle.