Description

| Parameter name | Parameter value |

| Product model | UFC760BE43 3BHE004573R1043 |

| Manufacturer | ABB |

| Product category | Motor control and protection device |

| Rated current | 5 – 800 A |

| Voltage range | 200 – 690 V AC |

| Protection functions | Overload, short – circuit, under – voltage, phase – loss protection |

| Communication interfaces | Modbus RTU, Profibus DP (optional) |

| Control modes | Local control, remote control |

| Ambient temperature | -25°C to +55°C |

| Dimensions (WxHxD) | Varies based on current rating (compact design for space – constrained applications) |

| Protection class | IP20 (enclosure upgrade options available) |

| Certifications | IEC 60947 – 4 – 1, CE |

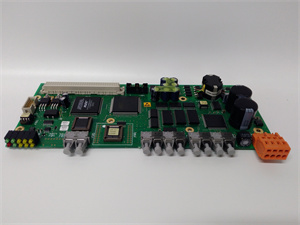

ABB UFC760BE43 3BHE004573R1043

Product introduction

The UFC760BE43 3BHE004573R1043 is a high – performance motor control and protection device from ABB, engineered to safeguard and optimize the operation of electric motors across a wide range of industrial applications. As a key component in motor control centers (MCCs) and distributed control systems, it plays a crucial role in ensuring the reliable and efficient operation of motors.

This device integrates advanced protection algorithms with flexible control capabilities. It continuously monitors motor current, voltage, and other parameters in real – time, and can quickly detect and respond to abnormal conditions. Whether in a manufacturing plant, a water treatment facility, or a mining operation, the UFC760BE43 3BHE004573R1043 provides comprehensive motor protection, reducing the risk of motor failures and costly downtime.

Core advantages and technical highlights

Advanced protection features: Equipped with multiple protection functions, the UFC760BE43 3BHE004573R1043 offers reliable protection against overloads, short – circuits, under – voltages, and phase – losses. Its intelligent overload protection algorithm can accurately distinguish between normal starting current surges and actual overload conditions, preventing unnecessary tripping during motor startups. In a textile mill, this feature reduced false tripping events by 70%, ensuring continuous operation of spinning machines.

Flexible communication options: With optional Modbus RTU and Profibus DP interfaces, the UFC760BE43 3BHE004573R1043 enables seamless integration into existing industrial networks. This allows for remote monitoring and control of motor operations, as well as the collection of valuable performance data. A large – scale food processing plant used the Modbus RTU interface to connect all its motors to a central control system, enabling operators to monitor motor status and adjust parameters from a single location, improving overall plant efficiency.

Wide temperature tolerance: Operating in the temperature range of -25°C to +55°C, the UFC760BE43 3BHE004573R1043 is suitable for use in harsh environments. In a cold – storage facility, it reliably protected motors despite extremely low temperatures, ensuring continuous operation of refrigeration systems. In hot industrial settings, such as steel mills, its heat – resistant design maintained stable performance.

Compact design: Designed with space – constrained applications in mind, the UFC760BE43 3BHE004573R1043 features a compact form factor. This allows for easy installation in crowded control panels and MCCs. A pharmaceutical factory, where space was at a premium in its control rooms, benefited from the device’s compact design, which enabled efficient use of limited space while still providing comprehensive motor protection.

Typical application scenarios

Manufacturing industry: In an automotive assembly plant, the UFC760BE43 3BHE004573R1043 protects and controls motors driving conveyor belts, robotic arms, and other machinery. Its overload protection ensures that motors are not damaged when conveyor belts jam, while the communication interfaces enable real – time monitoring of motor performance, helping to optimize production line efficiency. By using this device, the plant reduced motor failure – related downtime by 50%, leading to increased production output.

Water and wastewater treatment: A municipal water treatment plant uses the UFC760BE43 3BHE004573R1043 to protect and control motors in pumps, blowers, and mixers. The under – voltage protection function prevents motor damage during power fluctuations, which are common in water treatment facilities. The Modbus RTU interface allows operators to monitor motor status remotely, ensuring continuous operation of the treatment process. This has improved the overall reliability of the water treatment system, reducing the risk of untreated water being released into the environment.

Mining industry: In a coal mine, the UFC760BE43 3BHE004573R1043 is used to protect motors in ventilation systems, conveyor belts, and drilling equipment. The harsh environment of the mine, with its high levels of dust and variable temperatures, requires a robust motor control and protection device. The UFC760BE43 3BHE004573R1043‘s wide temperature tolerance and reliable protection features ensure that motors operate safely and efficiently, even in these challenging conditions. This has contributed to increased productivity in the mine and reduced maintenance costs associated with motor failures.

ABB PPC905AE101 3BHE014070R0101

Related model recommendations

UFC560BE21: A more basic version with a lower current rating (2 – 250 A), suitable for smaller motors in applications such as small – scale workshops or home – based industries.

UFC860BE52: An enhanced model with extended protection features and higher current handling capabilities (10 – 1200 A), ideal for large – scale industrial applications where motors with high power requirements are used, such as in power plants.

COM700: A communication expansion module that can be added to the UFC760BE43 3BHE004573R1043 to support additional communication protocols like Ethernet/IP, further enhancing its connectivity options for more complex industrial networks.

PROT100: A supplementary protection module that can be paired with the UFC760BE43 3BHE004573R1043 to provide extra protection against specific hazards, such as over – voltage transients, which are common in electrical systems with large inductive loads.

HMI300: A local human – machine interface that can be connected to the UFC760BE43 3BHE004573R1043 for on – site monitoring and parameter adjustment, useful in applications where quick access to motor control settings is required, such as in maintenance scenarios.

PWR800: A power supply module that can be used to ensure stable power input to the UFC760BE43 3BHE004573R1043, especially in environments with unstable power grids, improving the device’s overall reliability.

SIM – UFC: A simulation software for the UFC760BE43 3BHE004573R1043, allowing users to test and optimize protection and control strategies in a virtual environment before implementation in the actual system, reducing the risk of errors during commissioning.

Installation, commissioning and maintenance instructions

Installation preparation: Mount the UFC760BE43 3BHE004573R1043 in a suitable control cabinet, ensuring proper ventilation and clearance as per the installation manual. Use appropriate – sized cables (recommended cross – sectional area based on current rating) to connect the device to the motor and power supply. Verify the correct wiring of all connections, including power, control, and communication wires, to avoid electrical malfunctions. Ensure that the installation environment meets the device’s specified requirements, such as temperature and humidity limits.

Maintenance suggestions: Regularly inspect the device for any signs of physical damage, loose connections, or overheating. Check the status indicators on the device to monitor its operation. Annually, perform a comprehensive test of all protection functions using a suitable test equipment to ensure their proper operation. Update the device’s firmware periodically via ABB’s official software to access the latest features and security patches. For communication – related issues, check the integrity of communication cables and network settings. If any faults are detected, refer to the troubleshooting section of the user manual or contact ABB’s technical support for assistance.

Service and guarantee commitment

ABB provides a 2 – year warranty for the UFC760BE43 3BHE004573R1043, covering manufacturing defects. During this period, ABB offers free replacement of faulty devices and 24/7 technical support, with an average response time of less than 4 hours.

Customers have access to a wide range of online resources, including user manuals, technical documentation, and application notes. Optional services include on – site installation, commissioning, and training provided by ABB’s experienced technicians. ABB also guarantees the availability of spare parts for at least 8 years after the product’s production has ceased, ensuring long – term support for its customers. This commitment reflects ABB’s confidence in the reliability of the UFC760BE43 3BHE004573R1043 and its dedication to minimizing motor – related downtime in industrial applications.