Description

Detailed parameter table

| Parameter name | Parameter value |

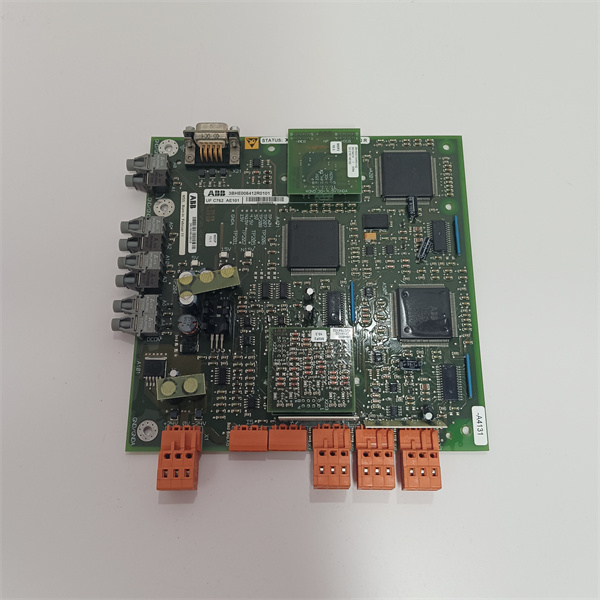

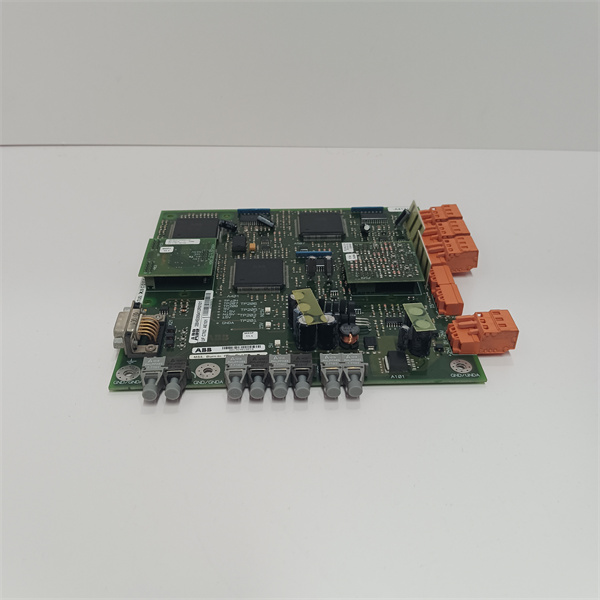

| Product model | UFC762AE101 3BHE006412R0101 |

| Manufacturer | ABB |

| Product category | Frequency Converter Control Unit |

| Rated supply voltage | 380 – 480 VAC, 50/60 Hz |

| Control algorithm | Advanced vector control for high – precision speed and torque control |

| Power range | Suitable for motors within a specific power range (check product manual for exact values) |

| Communication interfaces | Multiple options including Modbus, Profibus – DP (configurable) |

| Overload capacity | Can withstand short – term overloads up to a certain percentage (e.g., 150% for 60 seconds) |

| Protection class | IP20 for basic protection against solid objects and limited protection against water spray |

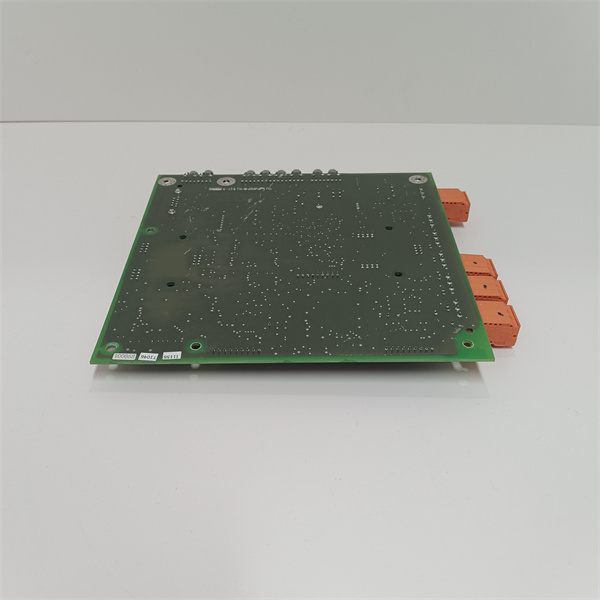

| Dimensions (approx.) | [Provide length x width x height in cm] for space planning |

| Cooling method | Forced air cooling to ensure stable operation under high – load conditions |

| Programmable functions | Multiple programmable digital and analog inputs/outputs for flexible integration |

ABB UFC762AE101 3BHE006412R0101

Product introduction

The ABB UFC762AE101 3BHE006412R0101 is a state – of – the – art Frequency Converter Control Unit, a cornerstone in ABB’s lineup of industrial power control solutions. Engineered with precision, it serves as the brain of a frequency converter system, dictating the operation of electric motors with remarkable accuracy.

This control unit is designed to interface seamlessly with a wide range of motors, regulating their speed and torque with finesse. By employing advanced vector control algorithms, it enables motors to operate at optimal efficiency across various industrial applications. Whether it’s in a manufacturing plant where precise motor control is crucial for product quality or in a large – scale industrial process where energy savings are a priority, the UFC762AE101 3BHE006412R0101 steps up to the challenge. Its ability to handle different power – rated motors and communicate with other industrial devices via multiple interfaces makes it an indispensable component in modern industrial automation setups.

Core advantages and technical highlights

Advanced control algorithm: The ABB UFC762AE101 3BHE006412R0101 utilizes advanced vector control, which provides unrivaled precision in speed and torque control. This means that motors can be operated with extremely low speed ripple, ensuring smooth operation in applications where precision is key, such as in high – end manufacturing machinery. The accurate torque control also enables better handling of varying loads, preventing motor stalling and enhancing overall system reliability.

Flexible communication options: With multiple communication interfaces like Modbus and Profibus – DP (configurable), the control unit can integrate effortlessly into existing industrial networks. This flexibility allows for seamless data exchange between the frequency converter and other components in the automation system, such as programmable logic controllers (PLCs) or supervisory control and data acquisition (SCADA) systems. It enables remote monitoring and control, giving operators the ability to manage motor operations from a central location.

Robust overload handling: Capable of withstanding short – term overloads up to a significant percentage (e.g., 150% for 60 seconds), the UFC762AE101 3BHE006412R0101 ensures continuous operation even in demanding scenarios. This feature is particularly useful in applications where motors may encounter sudden load spikes, such as in conveyor systems during start – up or when handling heavy materials. The forced air – cooling mechanism further supports its ability to handle high – load conditions without overheating, maintaining stable performance over extended periods.

Typical application scenarios

In manufacturing industries, the ABB UFC762AE101 3BHE006412R0101 finds extensive use in machine tools. For example, in a precision – machining center, it controls the spindle motor with high accuracy. The advanced vector control ensures that the spindle rotates at the exact speed required for different machining operations, whether it’s milling, drilling, or turning. This results in high – quality finished products with tight tolerances.

In the water and wastewater treatment sector, the control unit is employed to manage the pumps. Pumps in these facilities need to operate under varying load conditions depending on the water flow rate and pressure requirements. The UFC762AE101 3BHE006412R0101‘s ability to handle overloads and provide precise speed control ensures efficient pump operation. It can adjust the pump speed in real – time based on the water level or quality sensors’ data, saving energy and reducing wear and tear on the pumps.

Related model recommendations

UFC765AE102: Belongs to the same family as UFC762AE101 3BHE006412R0101. It may offer enhanced features such as higher power handling capabilities or additional communication protocols. This makes it suitable for more power – intensive applications or in setups where a wider range of communication options are required.

ACS880 – 01: A frequency converter by ABB that pairs perfectly with the UFC762AE101 3BHE006412R0101. The UFC762AE101 serves as the control unit for the ACS880 – 01, enabling precise control of motor speed and torque. Together, they form a reliable and efficient motor control solution for various industrial applications.

PLC – AC500: Can be integrated with the UFC762AE101 3BHE006412R0101 in an industrial automation system. The PLC can send control commands to the UFC762AE101 based on the overall process requirements, and the UFC762AE101 in turn controls the motor operation. This combination allows for complex automation sequences and centralized control.

AI583: An analog input module by ABB. It can be used to interface with sensors that provide analog data, such as temperature or pressure sensors. The AI583 collects this data and sends it to the UFC762AE101 3BHE006412R0101, which can then adjust the motor operation accordingly. This is useful in applications where motor control needs to be based on real – time process variables.

DI580: A digital input module. In an industrial setup, the DI580 can be used to interface digital signals from switches, relays, or other digital devices. These signals can be sent to the UFC762AE101 3BHE006412R0101 to trigger specific motor control actions, such as start, stop, or speed changes.

ABB UFC762AE101 3BHE006412R0101

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the ABB UFC762AE101 3BHE006412R0101, ensure that the installation area is clean, dry, and well – ventilated to support the forced air – cooling mechanism. Use appropriate electrical installation tools and follow all safety regulations. Verify that the supply voltage matches the unit’s rated voltage. Mount the unit securely in a control cabinet, making sure there is enough space around it for heat dissipation and easy access for future maintenance.

Maintenance suggestions: Regularly check the forced air – cooling fans for any signs of obstruction or wear. Clean the unit periodically to remove dust and debris that could affect its performance. Monitor the communication interfaces for any errors or disruptions. In case of motor control issues, first check the input power supply and then the control unit’s settings. If a component replacement is needed, always use genuine ABB spare parts to maintain the unit’s performance and reliability. Update the control unit’s firmware as new versions are released to benefit from the latest features and improvements.

Service and guarantee commitment

ABB stands firmly behind the UFC762AE101 3BHE006412R0101 with a comprehensive quality assurance program. The product comes with a standard one – year warranty, demonstrating ABB’s confidence in its durability and performance. In case of any product – related issues, ABB’s dedicated after – sales service team is available around the clock. They offer professional technical support, helping customers with installation, commissioning, and troubleshooting. Whether it’s a simple query about the unit’s operation or a complex technical problem, ABB’s experts are ready to provide prompt and effective solutions, ensuring that the UFC762AE101 3BHE006412R0101 continues to operate at its best and delivers maximum value to customers.