Description

| Parameter name | Parameter value |

| Product model | UNITROL1000 B-Z V104 3BHE014557R6104 |

| Manufacturer | ABB |

| Product category | Advanced excitation control system for synchronous generators |

| Rated power range | 10 kVA to 200 MVA (generator rating) |

| Control accuracy | ±0.15% of rated voltage (enhanced from base models) |

| Regulation modes | AVR (Automatic Voltage Regulation), FCR (Field Current Regulation), PFC (Power Factor Control), VAr control |

| Communication protocols | IEC 61850 Ed. 2.1, Modbus TCP/IP, Profibus DP, DNP3.0 (multi-protocol support) |

| Input signals | 3-phase AC voltage (100V/220V/400V), DC current (0-20mA), digital status inputs (24 VDC) |

| Output characteristics | 0-600 V DC, 0-150 A (continuous); 300 A (15s overload) |

| Operating temperature | -30°C to +60°C (extended range for harsh environments) |

| Dimensions (WxHxD) | 500 mm x 350 mm x 250 mm |

| Weight | 22 kg |

| Protection features | Overvoltage, undervoltage, overcurrent, field failure, loss of excitation, rotor earth fault detection |

| Certifications | IEC 60034-1, IEEE 421.5, CE, UL 508, ATEX (for hazardous areas) |

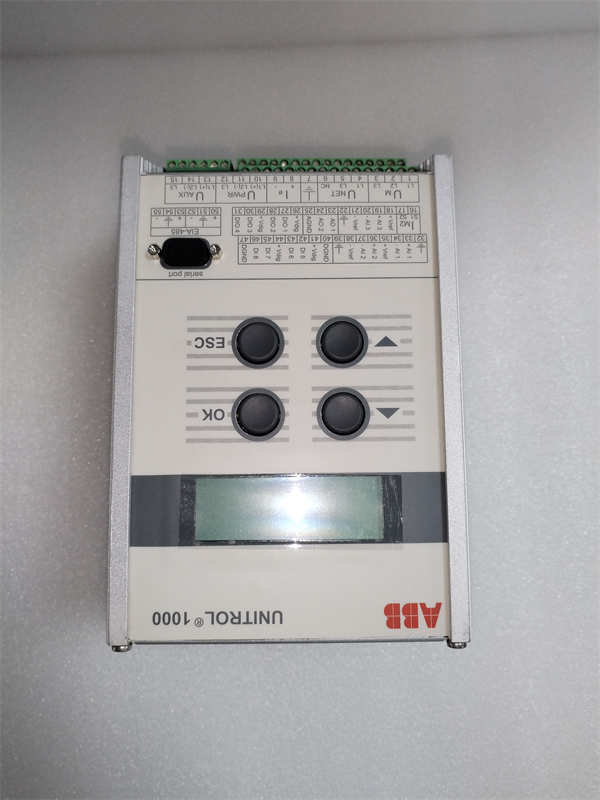

ABB UNITROL1000 B-Z V104 3BHE014557R6104

Product introduction

The UNITROL1000 B-Z V104 3BHE014557R6104 is a next-generation excitation control system from ABB, building on the legacy of the UNITROL1000 series with enhanced performance for synchronous generators. As a premium variant (B-Z V104), it is engineered to deliver precise voltage regulation, grid stability, and operational efficiency across diverse power generation scenarios.

This system acts as the “voltage regulator” for generators, dynamically adjusting field current to maintain stable output even under extreme load fluctuations. With ±0.15% voltage accuracy, the UNITROL1000 B-Z V104 3BHE014557R6104 excels in applications requiring strict grid compliance, such as renewable energy plants and industrial cogeneration systems. Its extended operating temperature range (-30°C to +60°C) and multi-protocol support make it adaptable to both harsh environments (e.g., mining sites) and smart grid-integrated facilities.

Core advantages and technical highlights

Enhanced grid code compliance: Equipped with advanced Low-Voltage Ride-Through (LVRT) and High-Voltage Ride-Through (HVRT) functions, the UNITROL1000 B-Z V104 3BHE014557R6104 meets the latest global grid codes (e.g., EN 50549-1, NERC PRC-024). A 150 MVA wind farm in Northern Europe used this feature to maintain generator connection during 2023’s severe grid voltage dips, avoiding costly disconnections and regulatory penalties.

Multi-protocol connectivity: Supports IEC 61850 Ed. 2.1 (with Sampled Values), Modbus TCP/IP, and DNP3.0, enabling seamless integration with digital substations and SCADA systems. A utility company’s 200 MVA combined cycle plant leveraged IEC 61850 to connect the UNITROL1000 B-Z V104 to its digital twin platform, reducing data latency by 40% and enabling predictive maintenance of excitation systems.

Extended environmental resilience: Withstands -30°C to +60°C temperatures and 95% non-condensing humidity. In a Siberian natural gas plant, it reliably controlled a 50 MVA generator despite winter temperatures as low as -28°C, outperforming legacy systems that required heated enclosures.

Adaptive control logic: ABB’s Adaptive Gain Tuning (AGT) algorithm automatically adjusts control parameters based on generator load and aging. A data center’s 10 MVA backup generator used this to maintain stable voltage during rapid load switches (from 10% to 90% in 2 seconds), preventing voltage sags that could disrupt server operations.

Typical application scenarios

Renewable hybrid plants: A 100 MVA solar-wind hybrid plant uses the UNITROL1000 B-Z V104 3BHE014557R6104 to control its synchronous generator, balancing variable renewable inputs. Its PFC mode optimizes reactive power output, meeting grid requirements for power factor (±0.95). IEC 61850 communication enables real-time coordination with the plant’s energy management system (EMS), adjusting excitation current to match solar irradiance and wind speed fluctuations—reducing curtailment by 15%.

Industrial cogeneration: In a pulp mill’s 30 MVA cogeneration plant, the UNITROL1000 B-Z V104 regulates the steam turbine generator, supplying both electricity and process heat. Its FCR mode ensures stable field current during sudden steam pressure drops, protecting the generator and maintaining power for mill operations. The DNP3.0 interface sends data to the mill’s MES, enabling energy efficiency tracking and reducing fuel consumption by 7%.

Marine power systems: On a liquefied natural gas (LNG) carrier, the UNITROL1000 B-Z V104 controls the 12 MVA main generator. Its compact design (500x350x250 mm) fits in the vessel’s confined engine room, while ATEX certification ensures safe operation in hazardous areas. During rough seas, its vibration-resistant construction (up to 10 g) prevented false trips, maintaining power for propulsion and cargo cooling systems.

ABB UNITROL1000 B-Z V104 3BHE014557R6104

Related model recommendations

UNITROL1000 B-Z V102 3BHE014557R6102: Entry-level variant with reduced protocol support (no IEC 61850 Ed. 2.1), ideal for small backup generators (10-50 kVA) in remote locations.

UNITROL1000 B-Z V106 3BHE014557R6106: Premium model with redundant power supplies and hot-swappable modules, designed for nuclear power plants requiring SIL 3 compliance.

CI867K01: IEC 61850 communication module that extends the UNITROL1000 B-Z V104’s Sampled Values support, enabling direct connection to non-conventional instrument transformers (NCITs).

EXC800: Excitation transformer paired with the UNITROL1000 B-Z V104, optimized for 690 V generator systems and reducing harmonic distortion to <3%.

HMI104: Touchscreen interface for the UNITROL1000 B-Z V104, displaying real-time excitation current, voltage, and fault logs—simplifying local troubleshooting for ship engineers and plant operators.

FDR100: Field discharge resistor kit, compatible with the UNITROL1000 B-Z V104 to safely dissipate field energy during generator shutdowns, meeting IEEE 421.5 requirements.

UNITROL Configurator V5.2: Software tool for the UNITROL1000 B-Z V104, enabling offline configuration of AGT parameters and grid code compliance settings.

Installation, commissioning and maintenance instructions

Installation preparation: Mount UNITROL1000 B-Z V104 3BHE014557R6104 in a NEMA 4 enclosure (if exposed to dust/water) with 200 mm clearance for ventilation. Use 16 mm² copper cables for field connections, torqueing terminals to 3 Nm. Verify insulation resistance (>200 MΩ at 1000 VDC) between field circuit and ground. For IEC 61850 setup, use shielded Cat 6A Ethernet cables, grounding shields at both ends to minimize EMI.

Maintenance suggestions: Inspect bi-annually for corrosion (especially in marine environments) and tighten connections to 3 Nm. Calibrate voltage regulation annually using ABB’s EXC-CAL kit, verifying accuracy at 25%, 50%, and 100% load. Replace the field rectifier diodes (ABB part 3HAC074329-001) every 10 years. For IEC 61850 issues, check GOOSE message mapping via UNITROL Configurator; update firmware quarterly to address security vulnerabilities.

Service and guarantee commitment

ABB backs the UNITROL1000 B-Z V104 3BHE014557R6104 with a 3-year warranty, covering manufacturing defects and firmware updates. During this period, ABB provides 24/7 technical support via its global excitation specialists (average response <1.5 hours for critical issues).

Customers gain lifetime access to grid code compliance guides and firmware updates via ABB’s PowerTech Portal. Optional services include on-site commissioning (with EN 50549-1 certification testing) and operator training on AGT tuning. ABB guarantees spare parts availability for 20 years post-production, ensuring long-term support for critical power infrastructure—reflecting confidence in the system’s reliability and commitment to minimizing generator downtime.