Description

Detailed parameter table

| Parameter name | Parameter value |

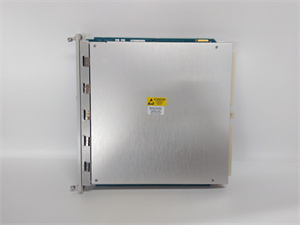

| Product model | 3500/22M |

| Manufacturer | Bently Nevada |

| Product category | Machinery Protection System Transient Data Interface Module |

| Channel configuration | 4 channels (supports up to 4 sensors) |

| Data capture rate | Up to 128,000 samples per second per channel |

| Frequency range | DC to 40 kHz |

| Input type | Proximity probe signals, vibration signals |

| Operating voltage | 5 VDC, ±15 VDC (from 3500/15 106M1079-01 power supply) |

| Power consumption | 10 W typical, 12 W maximum |

| Operating temperature | 0°C to +60°C (32°F to +140°F) |

| Form factor | 3500 system rack mount (2 slot width) |

| Dimensions | 266 mm (H) × 72 mm (W) × 229 mm (D) (10.5″ × 2.8″ × 9.0″) |

| Compatibility | 330180-X1-CN sensors, 3500/05 communication modules, 3500 racks |

| Certification | UL, CE, RoHS compliant, IEC 61010-1 approved |

BENTLY 3500/22M

Product introduction

The 3500/22M from Bently Nevada is a high-performance transient data interface module in the 3500 Machinery Protection System, specialized in capturing and analyzing high-speed vibration and position data from rotating machinery. This 2-slot module acts as a critical bridge between primary sensors like the 330180-X1-CN and the broader monitoring ecosystem, enabling detailed transient analysis that reveals machinery behaviors not captured by standard monitoring. As an advanced diagnostic tool, the 3500/22M complements continuous protection modules by providing deep insights into machinery dynamics during startup, shutdown, or alarm conditions.

Bently Nevada’s 3500/22M connects directly to proximity probes and vibration sensors, capturing high-resolution transient data at rates up to 128,000 samples per second. Installed in 3500 series racks and powered by 3500/15 106M1079-01 supplies, it processes raw sensor signals to identify transient events like rotor rubs, surge conditions, or impact faults. This detailed data is then shared with analysis tools via 3500/05 communication modules, supporting advanced diagnostics, root cause analysis, and predictive maintenance strategies in critical industrial applications.

Core advantages and technical highlights

High-speed data acquisition: A defining feature of the 3500/22M is its ability to capture transient data at up to 128,000 samples per second per channel across its 4 channels. This high resolution is essential for analyzing fast-moving events like turbine blade passing frequencies, gear mesh vibrations, or transient rotor dynamics that standard monitoring modules might miss.

Broad frequency coverage: With a frequency range from DC to 40 kHz, the module captures both low-frequency positional changes and high-frequency vibration components, providing comprehensive machinery dynamics analysis. This range ensures detection of subtle fault signatures in bearings, gears, and rotating components monitored by 330180-X1-CN sensors.

Triggered data capture: The module supports multiple trigger conditions (alarm signals, manual activation, or pre-programmed events) to capture relevant transient data without continuous high-speed recording. This efficient data capture minimizes storage requirements while ensuring critical events are documented for analysis.

Seamless ecosystem integration: 3500/22M integrates fully with the 3500 ecosystem, receiving raw signals from 330180-X1-CN sensors and sharing processed transient data with 3500/05 communication modules. This integration allows transient data to be correlated with continuous monitoring data, providing a complete picture of machinery health during both steady-state and transient operations.

Typical application scenarios

Turbine startup/shutdown analysis

In power generation, 3500/22M modules capture transient data during turbine startups and shutdowns when machinery undergoes significant speed and load changes. Connected to 330180-X1-CN sensors monitoring shaft vibration, the module records critical speed crossings, thermal growth effects, and transient vibrations that indicate potential issues like rubs or misalignment. This data is analyzed to optimize startup procedures and detect emerging faults, with insights shared via 3500/05 modules to asset management systems.

Compressor surge monitoring

Oil and gas facilities use 3500/22M to monitor compressor surge events—destructive transient conditions where gas flow reverses. The module captures high-speed pressure and vibration data from sensors during surge events, providing detailed analysis of surge characteristics. This information helps engineers adjust anti-surge controls and identify early surge indicators, preventing damage to compressor components. Transient data is correlated with steady-state measurements from 3500/44M 176449-03 modules for comprehensive analysis.

Motor fault diagnostics

Manufacturing plants utilize 3500/22M to diagnose intermittent motor issues by capturing transient vibration data during startup, load changes, or fault conditions. The module records vibration signatures from 330180-X1-CN sensors that reveal rotor bar defects, bearing flaws, or electrical anomalies. This detailed diagnostic data, transmitted via 3500/05 communication modules to maintenance systems, enables precise fault identification and targeted repairs, reducing unplanned downtime.

BENTLY 3500/22M

Related model recommendations

330180-X1-CN: Proximity sensor providing raw vibration data to 3500/22M.

3500/05 series: Communication modules transmitting transient data to analysis systems.

3500/44M 176449-03: Monitoring module providing steady-state data for correlation.

3500/15 106M1079-01: Power supply module supporting the transient data module.

3500/25 184684-01: Relay module triggering protective actions based on transient events.

133300-01: Interface cable facilitating data flow from communication modules.

3500/60 163179-01: Display module showing transient event status and alerts.

330130 series: Extension cables connecting sensors to the transient module.

Installation, commissioning and maintenance guidelines

Installation

Install 3500/22M in a 3500 series rack with a properly configured 3500/15 106M1079-01 power supply, ensuring two adjacent slots are available. Connect 330180-X1-CN sensors to the module using shielded extension cables, routing them away from noise sources to preserve signal integrity. Establish backplane communication with other 3500 modules, including 3500/05 communication modules for data transmission. Secure all connections with appropriate torque (0.5-0.6 N·m) to prevent vibration-induced loosening.

Commissioning

After installation, configure 3500/22M using 3500 configuration software to set sample rates, trigger conditions, and data storage parameters. Calibrate input channels to match connected 330180-X1-CN sensors, verifying sensitivity and linearity across the measurement range. Test triggered data capture using simulated events to ensure proper operation. Establish communication parameters with 3500/05 modules to ensure seamless transient data transmission to analysis systems. Document configuration settings and baseline transient patterns for future reference.

Maintenance

Include 3500/22M in quarterly system inspections, verifying status indicators and ensuring proper power supply from 3500/15 106M1079-01 modules. Check sensor connections for corrosion or looseness, cleaning contacts if necessary. Verify data capture functionality by triggering test recordings periodically. Monitor storage capacity to ensure adequate space for transient events. Update firmware during scheduled system upgrades to maintain compatibility with sensors and communication modules. Replace the module if data capture errors persist after troubleshooting.

Service and guarantee commitment

Bently Nevada provides the 3500/22M with a 36-month warranty covering manufacturing defects and performance issues under normal operating conditions, including data capture accuracy, trigger functionality, and component reliability when powered by compatible supplies like 3500/15 106M1079-01. Our technical support team offers expert guidance on module configuration, transient analysis, and integration with sensors like 330180-X1-CN and communication modules like 3500/05.

We offer specialized training on transient data analysis, vibration diagnostics, and system optimization specific to 3500/22M. Beyond the warranty period, our service agreements include performance verification, technical support, and expedited replacement services to ensure continuous transient monitoring capability. Bently Nevada’s commitment to quality ensures reliable high-speed data capture throughout the module’s operational lifecycle, backed by our global network of service professionals.