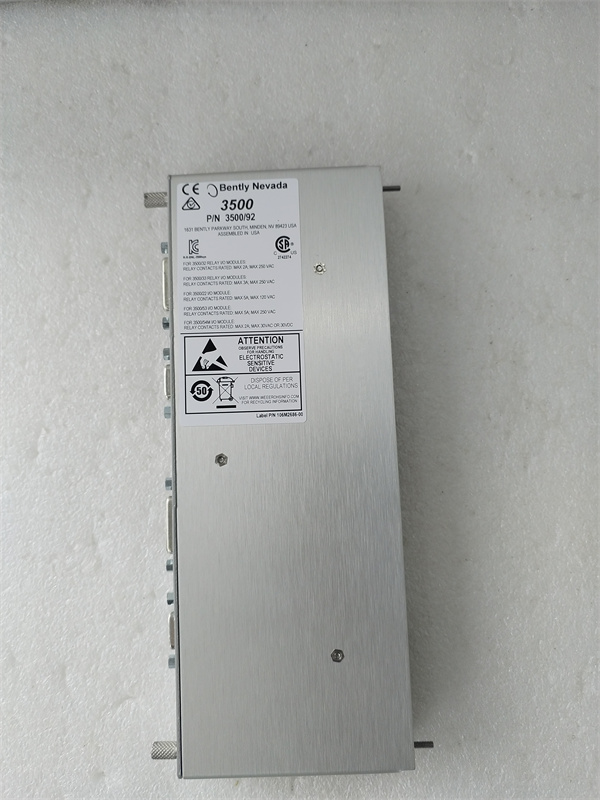

Description

1. Detailed parameter table

| Parameter name | Parameter value |

| Product model | 133323-01 |

| Manufacturer | BENTLY NEVADA |

| Product category | Vibration Transmitter Module |

| Series | 1900/65 |

| Input type | Accelerometer, velocity sensor (IEPE compatible) |

| Output signal | 4-20 mA DC (proportional to vibration amplitude) |

| Measurement range | 0-50 mm/s (velocity), 0-50 g (acceleration) |

| Frequency response | 1 Hz to 10 kHz |

| Input voltage | 18-30 V DC |

| Operating temperature | -40°C to +85°C (-40°F to +185°F) |

| Storage temperature | -55°C to +125°C (-67°F to +257°F) |

| Housing material | Die-cast aluminum with epoxy coating |

| Dimensions | 89 mm x 57 mm x 32 mm (3.50 in x 2.24 in x 1.26 in) |

| Weight | 0.22 kg (0.48 lbs) |

| Protection rating | NEMA 4X/IP66 (waterproof, dustproof, corrosion-resistant) |

| Certifications | ATEX, IECEx, UL, CSA, RoHS |

BENTLY 133323-01

2. Product introduction

The BENTLY NEVADA 133323-01 is a rugged vibration transmitter module, part of the 1900/65 series, designed to convert vibration signals from accelerometers or velocity sensors into industry-standard 4-20 mA outputs. This critical component bridges the gap between field sensors and control systems, enabling real-time monitoring of machinery health in harsh industrial environments.

As a key element in condition monitoring systems, the 133323-01 processes raw vibration data—whether measuring velocity (mm/s) or acceleration (g)—and converts it into a proportional current signal. This allows integration with PLCs, DCS, SCADA systems, and data loggers, making it indispensable for tracking equipment performance in turbines, pumps, motors, and compressors. By delivering consistent, reliable data, the 133323-01 empowers operators to detect early signs of wear, imbalance, or misalignment, reducing unplanned downtime and maintenance costs.

3. Core advantages and technical highlights

Dual-mode compatibility: The 133323-01 accepts inputs from both accelerometers and velocity sensors, offering flexibility across applications. In a chemical plant, for example, it can connect to an accelerometer on a high-speed centrifugal pump (measuring up to 50 g) and a velocity sensor on a slow-speed mixer (tracking 0-50 mm/s), eliminating the need for separate transmitters.

Extreme environment durability: With an IP66 rating and operating range of -40°C to +85°C, the 133323-01 thrives in harsh conditions. In offshore oil rigs, where salt spray and temperature swings are common, its epoxy-coated aluminum housing resists corrosion, while internal components remain stable—unlike plastic-bodied transmitters that degrade over time.

High-accuracy signal conversion: The module maintains ±0.5% full-scale accuracy across its frequency range (1 Hz to 10 kHz). In a power plant turbine, this precision ensures that subtle vibration increases (as small as 0.1 mm/s) are captured, enabling predictive maintenance before catastrophic failure. Its low noise floor (≤50 µV) further enhances signal integrity in high-electromagnetic interference (EMI) environments.

Simplified integration: The 4-20 mA output is universally compatible with industrial control systems, reducing setup time. Unlike complex digital protocols, the analog signal of the 133323-01 requires minimal configuration—simply connect to a PLC input card and scale the current range to match the vibration parameter, making it ideal for retrofits in legacy systems.

4. Typical application scenarios

Pump monitoring: In water treatment facilities, the 133323-01 is paired with an accelerometer on centrifugal pump bearings. It converts vibration data into a 4-20 mA signal, which a PLC uses to trigger alerts when velocity exceeds 15 mm/s—indicating bearing wear. This allows maintenance crews to replace bearings during scheduled outages, avoiding unplanned shutdowns that disrupt water supply.

Motor health tracking: In manufacturing plants, the 133323-01 monitors induction motor vibration. Mounted on the motor frame, it connects to a velocity sensor and sends data to a SCADA system. By tracking trends over time, operators can identify rotor imbalance (characterized by 1x frequency vibration) and schedule balancing before the motor overheats or fails.

Turbine auxiliary systems: In combined-cycle power plants, the 133323-01 monitors vibration in turbine lube oil pumps. Operating in high-temperature environments (up to 85°C), it reliably transmits data to the DCS, ensuring pumps maintain proper pressure. A sudden spike in the 4-20 mA signal triggers an alarm, preventing oil starvation and turbine damage.

BENTLY 133323-01

5. Related model recommendations

330703-000-060-10-02-00: A velocity sensor optimized for use with the 133323-01, ideal for measuring low-frequency vibration in motors and pumps (0.1-100 mm/s).

133323-02: A variant of the 133323-01 with a 0-10 V DC output, suitable for systems requiring voltage-based signals instead of 4-20 mA.

136188-01: A shielded cable that connects the 133323-01 to sensors, minimizing EMI in industrial environments with high electrical noise.

3500/42M Vibration Monitor: Integrates with the 133323-01 in the 3500 system, combining the transmitter’s data with advanced diagnostics for turbine and compressor protection.

990-04-50-01-00: A proximitor system that, when used alongside the 133323-01, provides a complete condition monitoring solution—tracking both vibration (via 133323-01) and shaft position (via 990-04-50-01-00).

6. Installation, commissioning and maintenance instructions

Installation preparation: Before mounting the 133323-01, verify the 18-30 V DC power supply is regulated and grounded. Use M4 screws (maximum torque 2 Nm) to attach the transmitter to a flat, vibration-free surface—avoid mounting directly on motor housings to prevent measurement interference. Route sensor cables (e.g., 136188-01) separately from power lines, and seal cable entries with PTFE tape to maintain IP66 integrity. Calibrate using a vibration calibrator: apply a 10 mm/s input and adjust the zero/span potentiometers to output 8 mA (mid-range).

Maintenance suggestions: Inspect the 133323-01 quarterly for loose connections or corrosion—clean terminals with isopropyl alcohol if needed. Annually, verify accuracy using a shaker table: at 25 mm/s, the output should be 12 mA (±0.06 mA). If drift exceeds ±1%, replace the internal calibration resistor (BENTLY P/N 133323-99-01). Check the housing seals yearly to ensure IP66 protection; replace O-rings if cracks are found to prevent moisture ingress.

7. Service and guarantee commitment

BENTLY NEVADA provides a 3-year warranty for the 133323-01, covering defects in materials and workmanship. Their technical support team offers 24/7 assistance for installation, calibration, and troubleshooting via phone or email. Customers gain access to online tools, including wiring diagrams and calibration procedures. For critical applications, BENTLY offers on-site validation to ensure the 133323-01 meets performance specifications. Spare parts are available for 10 years post-production, ensuring long-term reliability for industrial monitoring systems relying on this transmitter.