Description

Detailed parameter table

| Parameter name | Parameter value |

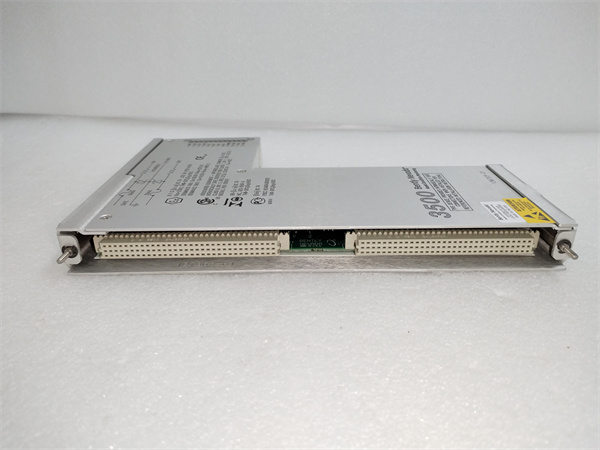

| Product model | 136703-01 |

| Manufacturer | BENTLY NEVADA |

| Product category | Cable Assembly (for 3300 XL Proximity Systems) |

| Cable length | 5 meters (16.4 feet) |

| Connector type | Microdot to BNC, compatible with 3300 XL probes and test equipment |

| Cable type | Shielded, low-noise, high-flexibility coaxial cable |

| Conductor gauge | 24 AWG (0.205 mm²) |

| Operating temperature | -40°C to +121°C |

| Shielding | Dual-layer (foil + braided copper, 95% coverage) |

| Jacket material | Flame-retardant, chemical-resistant polyurethane |

| Voltage rating | 500 V AC/DC |

| Impedance | 50 ohms (optimized for signal integrity) |

| Compatibility | Works with 330104-11-25-10-02-00 probes and calibration tools |

| Certifications | RoHS compliant, meets MIL-DTL-17 standards |

BENTLY 136703-01

Product introduction

The BENTLY NEVADA 136703-01 is a specialized cable assembly designed to bridge 3300 XL eddy current probes and calibration/test equipment. As a critical link in machinery monitoring system maintenance, it ensures accurate signal transmission during setup, calibration, and troubleshooting of probes like the 330104-11-25-10-02-00.

In industrial condition monitoring, precise calibration of eddy current probes is essential to maintain measurement accuracy. The 136703-01 facilitates this by providing a low-loss signal path between field probes and laboratory-grade calibration tools. Its microdot connector mates with probes, while the BNC connector interfaces with oscilloscopes, signal analyzers, or proximitor testers. This allows technicians to verify probe sensitivity (7.87 V/mm for the 330104-11-25-10-02-00), check linearity, and diagnose signal issues without disrupting installed systems. By ensuring reliable signal transfer during these processes, the 136703-01 helps maintain the integrity of the entire 3300 XL monitoring chain.

Core advantages and technical highlights

Typical application scenarios

In power plant maintenance, the BENTLY NEVADA 136703-01 is used to calibrate 330104-11-25-10-02-00 probes installed on turbine shafts. Technicians disconnect the probe from the 330180-91-CN proximitor and connect it to a calibration fixture via the 136703-01 cable. This setup allows precise measurement of output sensitivity, ensuring it meets the 7.87 V/mm specification. By verifying calibration annually, the plant maintains accurate vibration monitoring, preventing false alarms and ensuring early detection of turbine issues.

In manufacturing facilities, the cable assembly is used for troubleshooting faulty probes. When a 330104-11-25-10-02-00 probe shows erratic readings, technicians use the 136703-01 to connect it to an oscilloscope, checking for signal noise or distortion. This helps identify whether the issue lies with the probe, cable, or proximitor. In one automotive plant, this process reduced diagnostic time for pump vibration sensors by 60%, minimizing production downtime.

BENTLY 136703-01

Related model recommendations

330104-11-25-10-02-00: Eddy current probe that connects to the 136703-01 during calibration and testing, ensuring accurate sensitivity verification.

330180-91-CN: Proximitor sensor that works with the probe; the 136703-01 can also test signal transmission between the two components.

136703-02: 10-meter version of the 136703-01, suitable for testing probes in hard-to-reach locations.

9100-01 Calibration Fixture: Works with the 136703-01 to provide precise gap settings for calibrating 330104-11-25-10-02-00 probes.

79492-01: Extension cable for permanent installations; the 136703-01 is its temporary counterpart for maintenance.

3300 XL Proximitor Tester: Device that uses the 136703-01 to verify proximitor performance with connected probes.

1701/15: Vibration transmitter; while not directly connected to the 136703-01, it benefits from accurate probe calibration ensured by the cable.

Installation, commissioning and maintenance instructions

Installation preparation: Before using the BENTLY NEVADA 136703-01, inspect connectors for damage or corrosion. Clean microdot and BNC connectors with isopropyl alcohol and a lint-free cloth. Ensure the probe (e.g., 330104-11-25-10-02-00) is powered down before connecting. Mate the microdot connector with a ¼-turn twist until snug—avoid over-tightening. Connect the BNC end to test equipment, ensuring the locking mechanism clicks into place. Use cable ties to secure excess cable, avoiding sharp bends that exceed the 12mm minimum radius.

Maintenance suggestions: Inspect the 136703-01 before each use for jacket cracks, shield exposure, or connector wear. Test continuity with a multimeter (resistance <1Ω for conductors, >100 MΩ for insulation). Clean connectors after each use to prevent contamination. Store the cable in a coiled position (minimum 20cm diameter) in a dry case when not in use. Replace the assembly if signal loss exceeds 3dB at 10 kHz or if connectors fail to lock securely.

Service and guarantee commitment

BENTLY NEVADA provides a 1-year warranty for the 136703-01, covering defects in materials and workmanship. The technical support team offers 24/7 assistance for proper usage, including guidance on connecting to 330104-11-25-10-02-00 probes and calibration tools.

Customers can access wiring diagrams and maintenance guides via BENTLY NEVADA’s online portal. The company ensures spare part availability for 5 years post-production. This commitment ensures that the 136703-01 remains a reliable tool for maintaining the accuracy of critical machinery monitoring systems.