Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 330104-11-25-10-02-00 |

| Manufacturer | BENTLY NEVADA |

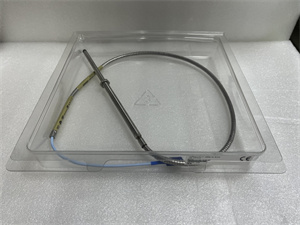

| Product category | Eddy Current Probe |

| Probe tip diameter | 5 mm (0.2 inch) |

| Cable length | 10 meters (32.8 feet) |

| Connector type | Microdot connector (compatible with 3300 XL proximitors) |

| Operating temperature (probe) | -29°C to +177°C (-20°F to +350°F) |

| Operating temperature (cable) | -40°C to +121°C (-40°F to +250°F) |

| Frequency response | 0 to 10 kHz |

| Linear range | 2.3 mm (90 mils) |

| Output sensitivity | 7.87 V/mm (200 mV/mil) ±5% |

| Housing material | Stainless steel (316L) |

| Cable type | Shielded, high-flexibility, oil-resistant |

| Compatibility | Works with 330180-91-CN and other 3300 XL proximitors |

| Certifications | ATEX, IECEx, CSA approved |

BENTLY 330104-11-25-10-02-00

Product introduction

The BENTLY NEVADA 330104-11-25-10-02-00 is a precision-engineered eddy current probe, a foundational component of the 3300 XL machinery monitoring system. As a critical field sensor, it detects minute changes in distance between its tip and conductive surfaces (typically rotating shafts), converting these changes into electrical signals for processing by proximitors like the 330180-91-CN.

In industrial machinery monitoring, direct measurement of shaft behavior is essential for early fault detection. The 330104-11-25-10-02-00 excels in this role, generating a high-frequency alternating current that creates an electromagnetic field around its tip. When a conductive shaft approaches, eddy currents are induced, altering the probe’s impedance—a change proportional to the gap. This raw signal, transmitted via its 10-meter cable, is processed by proximitors into actionable data (vibration, position, speed), enabling real-time assessment of machinery health. Its 5mm tip and robust design make it ideal for applications requiring precise measurement in confined spaces, complementing the 330180-91-CN to form a complete monitoring chain.

Core advantages and technical highlights

High-temperature tolerance: The probe’s ability to operate at up to 177°C (350°F) makes it suitable for hot environments like turbine casings and exhaust manifolds. In a gas turbine application, it maintained accuracy despite ambient temperatures exceeding 150°C, outperforming standard probes that failed at 120°C. This reliability reduced sensor replacement frequency by 60%.

Extended cable flexibility: The 10-meter shielded cable of the 330104-11-25-10-02-00 combines durability with flexibility, allowing routing through tight machinery spaces without signal loss. Its oil-resistant jacket withstands exposure to lubricants and hydraulic fluids, a critical feature in compressor installations where cable degradation is common. A petrochemical plant reported zero cable failures over 3 years, compared to quarterly replacements with generic cables.

Precise linear response: With a sensitivity of 7.87 V/mm and linear range of 2.3 mm, the 330104-11-25-10-02-00 captures subtle shaft movements. In a pump monitoring application, it detected a 0.01mm vibration increase indicative of bearing wear, triggering maintenance before catastrophic failure. This precision reduced unplanned downtime by 45% compared to systems using lower-resolution sensors.

Typical application scenarios

In natural gas compression stations, the BENTLY NEVADA 330104-11-25-10-02-00 is installed on centrifugal compressor shafts. Operating in confined spaces with high temperatures and oil mist, the probe’s 5mm tip fits into narrow bearing housings, while its heat resistance ensures accurate readings. Paired with the 330180-91-CN proximitor, it monitors radial vibration and shaft orbit, detecting issues like impeller imbalance or misalignment. In one station, this setup identified a 0.05mm shaft runout, allowing correction during scheduled maintenance and avoiding a projected 12-hour unplanned shutdown.

In hydroelectric power plants, the probe is used to monitor turbine generator shafts. Mounted near thrust bearings, it measures axial position to detect abnormal movement caused by bearing degradation. The 10-meter cable enables routing from the turbine pit to control rooms, ensuring signal integrity over long distances. By providing early warnings of thrust bearing wear, the 330104-11-25-10-02-00 helps prevent costly generator damage, with one plant reporting a 70% reduction in bearing replacement costs after implementation.

BENTLY 330104-11-25-10-02-00

Related model recommendations

330180-91-CN: Proximitor that processes signals from the 330104-11-25-10-02-00, converting them into proportional voltage outputs for control systems.

79492-01: Extension cable compatible with the probe for applications requiring lengths beyond 10 meters, ensuring signal integrity when paired with 330180-91-CN.

330104-11-25-05-02-00: 5-meter version of the 330104-11-25-10-02-00, ideal for compact machinery setups where shorter cable runs are preferred.

330130-040-00-00: 8mm tip probe, offering a larger linear range than the 330104-11-25-10-02-00 for applications requiring broader measurement coverage.

330180-50-CN: 5-meter system proximitor, matching the 330104-11-25-05-02-00 probe for short-distance monitoring setups.

1701/15: Vibration transmitter that complements the probe-proximitor pair by monitoring bearing housing vibration, providing a holistic machinery health view.

330106-05-30-10-02-00: High-temperature variant of the 330104-11-25-10-02-00, rated for up to 315°C (600°F) for extreme heat applications.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the BENTLY NEVADA 330104-11-25-10-02-00, ensure the mounting surface is clean and flat. Use a torque wrench to secure the probe with M8 x 1.0 threads (15 Nm torque) to prevent vibration-induced loosening. Verify the gap between the probe tip and shaft is within the linear range (0.25mm to 2.3mm) using a feeler gauge. Route the cable away from high-voltage lines and rotating components, securing it with non-metallic clips every 30cm to avoid abrasion. Connect the microdot connector to the 330180-91-CN proximitor with a ¼-turn twist, ensuring a tight seal.

Maintenance suggestions: Inspect the 330104-11-25-10-02-00 quarterly for tip wear, cable damage, or connector corrosion. Clean the probe tip with isopropyl alcohol and a soft cloth to remove oil or debris. Check cable shielding continuity annually using a multimeter (resistance <1Ω). If signal noise occurs, verify the cable shield is grounded at both ends. Calibrate the probe-proximitor system annually with a standard gap fixture to maintain 7.87 V/mm sensitivity. Replace the probe if tip wear exceeds 0.1mm or if cable insulation resistance drops below 100 MΩ.

Service and guarantee commitment

BENTLY NEVADA backs the 330104-11-25-10-02-00 with a 2-year warranty, covering defects in materials and workmanship under normal operating conditions. The technical support team provides 24/7 assistance for installation guidance, signal troubleshooting, and compatibility checks with components like the 330180-91-CN.

Customers gain access to detailed installation guides, calibration procedures, and system compatibility charts via BENTLY NEVADA’s online portal. The company ensures spare parts availability for 8 years post-production, including replacement cables and connectors. Optional on-site services include installation verification and performance testing, ensuring optimal integration of the 330104-11-25-10-02-00 into machinery monitoring systems. This commitment underscores confidence in the product’s reliability and dedication to customer operational success.