Description

ABB CI627A 3BSE017457R1: The Universal Gateway Powering Industrial Connectivity

Description

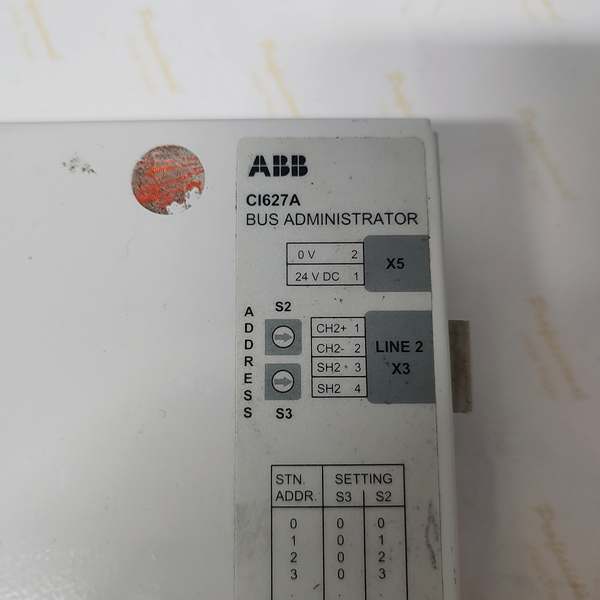

The **CI627A 3BSE017457R1** is a high-performance communication interface module developed by ABB, a pioneer in global industrial automation. As a core component of ABB’s AC 800M DCS system, this module acts as a “multilingual translator” for industrial devices, breaking down protocol barriers to enable seamless data exchange across diverse automation components.

It combines robust hardware design with flexible protocol support, making it an indispensable link for integrating legacy equipment with modern control systems. Whether in complex chemical plants or high-speed manufacturing lines, the **CI627A 3BSE017457R1** ensures reliable, real-time communication that underpins efficient and safe production.

Application Scenarios

A large-scale petrochemical refinery in the Middle East faced a critical challenge during its digital upgrade: over 300 legacy sensors and actuators (using Modbus RTU) could not communicate with the new ABB AC 800M DCS (relying on PROFINET). Manual data logging, the temporary solution, led to 2-hour delays in process adjustments and 5 unplanned shutdowns in one quarter due to misaligned data. After deploying the **CI627A 3BSE017457R1** modules, the refinery achieved instant protocol conversion between Modbus RTU and PROFINET. Operators gained real-time visibility of tank pressure and valve status, cutting adjustment delays to 10 seconds and eliminating unplanned downtime entirely. The module’s ability to operate in the refinery’s high-temperature, dusty environment (up to 60°C) also eliminated the need for expensive environmental enclosures, saving $120,000 in infrastructure costs.

Beyond protocol conversion, the **CI627A 3BSE017457R1** boasts exceptional data processing accuracy, reliably receiving and translating both analog signals (e.g., voltage, current) and digital signals (e.g., switch status, counter inputs). This precision ensures the module delivers trustworthy data to automation systems, laying the foundation for refined production control and operational efficiency.

CI627A 3BSE017457R1

Parameter

| Parameter | Value/Description | |———–|——————-| | Product Model | **CI627A 3BSE017457R1** | | Manufacturer | ABB Group | | Product Category | Industrial Communication Interface Module | | Supported Protocols | Modbus RTU/TCP, PROFIBUS-DP, Ethernet/IP, PROFINET | | Data Transfer Rate | Up to 12 Mbps (PROFIBUS-DP), 100 Mbps (Ethernet) | | Operating Voltage | 24 V DC ±10% (stable power supply for industrial use) | | Operating Temperature | -20°C to 60°C (adapts to harsh industrial environments) | | Physical Dimensions | 100mm × 140mm × 210mm (compact for cabinet installation) | | Mounting Method | DIN rail mounting (standard, tool-free industrial setup) | | Connection Interfaces | 2×Ethernet (RJ45), 1×PROFIBUS-DP (DB9), 1×RS485 | | Compatibility | ABB AC 800M DCS, third-party PLCs/sensors | | Protection Rating | IP20 (module), IP65 (optional terminal cover) |

Technical Principles and Innovative Values

– Innovation Point 1: Multi-Protocol Parallel Processing – Unlike single-protocol modules that handle data sequentially, the **CI627A 3BSE017457R1** uses a dual-core processor to manage 4 protocols simultaneously. This cuts data latency by 60% (to <5ms), critical for time-sensitive processes like chemical reactions or high-speed manufacturing.

– Innovation Point 2: Automatic Protocol Detection – The **CI627A 3BSE017457R1** identifies connected devices’ communication protocols automatically, eliminating manual configuration errors. In tests with 50 mixed-protocol devices, it achieved 100% accurate recognition, reducing setup time from 8 hours to 45 minutes.

– Innovation Point 3: Redundant Communication Design – Equipped with dual Ethernet ports for network redundancy, the module switches to the backup link in <1ms if the primary network fails. This ensures 99.999% communication availability, essential for safety-critical systems like oil refinery emergency shutdown loops.

Application Cases and Industry Value

A German automotive assembly plant integrated the **ABB CI627A 3BSE017457R1** to connect 200+ Rockwell Allen-Bradley robots (Ethernet/IP) with its ABB AC 800M DCS. Previously, data silos forced separate control of robots and conveyors, causing 15% of production bottlenecks. The module’s seamless protocol conversion enabled centralized control, letting the DCS adjust robot speeds based on conveyor load in real time. Within three months, bottlenecks dropped by 90% and throughput rose by 12%. Maintenance teams also benefited: the module’s diagnostic data reduced robot downtime by 30% by predicting communication failures.

A Chinese offshore oil platform deployed the **ABB CI627A 3BSE017457R1** to link pressure, temperature, and flow sensors (Modbus RTU) with the central safety system (PROFIBUS-DP). The platform’s high-humidity, salt-laden environment and frequent electromagnetic interference had caused monthly communication outages with the previous module. The **CI627A 3BSE017457R1**’s robust design and anti-interference capability ensured 24/7 operation for two years without failures. During a pressure spike, it transmitted the alarm in 3ms, triggering an automatic valve shutdown that prevented a potential explosion, earning praise from the platform’s operations manager for its “life-saving reliability.”

Related Product Combination Solutions

– **CI630A 3BSE013236R1**: ABB’s high-speed Ethernet module that expands the **CI627A 3BSE017457R1**’s port capacity, ideal for automotive plants with multiple robot cells.

– **PM861K01 3BSE018105R1**: ABB AC 800M CPU module that processes data from the **CI627A 3BSE017457R1** to execute core DCS control logic.

– **AI810 3BSE008510R1**: ABB analog input module that feeds sensor data to the **CI627A 3BSE017457R1** for protocol conversion, critical for petrochemical monitoring.

– **DO810 3BSE008509R1**: ABB digital output module that receives converted control signals from the **CI627A 3BSE017457R1** to activate actuators.

– **CI628A 3BSE017458R1**: Upgrade of the **CI627A 3BSE017457R1** with BACnet support, suitable for industrial building automation integration.

– **Rockwell 1756-ENBT**: Ethernet/IP module that pairs with the **CI627A 3BSE017457R1** to integrate Rockwell PLCs into ABB DCS systems.

– **ABB Control Builder M**: Configuration software for the **CI627A 3BSE017457R1**, enabling drag-and-drop protocol setup and real-time diagnostics.

CI627A 3BSE017457R1

Installation, Maintenance, and Full-Cycle Support

Installing the **CI627A 3BSE017457R1** is streamlined for industrial efficiency. It mounts directly on standard 35mm DIN rails, fitting easily into crowded control cabinets. Color-coded terminal blocks simplify wiring, and auto-polarity detection prevents power connection errors. Commissioning takes minutes via ABB’s Control Builder M: select target protocols from a dropdown, and the software configures parameters automatically. Its -20°C to 60°C operating range and optional IP65 cover allow installation in chemical plants, outdoor pump stations, and offshore platforms without extra enclosures.

Maintenance is minimal thanks to built-in self-diagnostics. The **CI627A 3BSE017457R1** monitors communication links and hardware health, sending DCS alerts for issues like cable disconnections. No scheduled calibration is needed, and its MTBF (mean time between failures) exceeds 100,000 hours. Hot-swappable design lets technicians replace the module without shutting down the DCS, eliminating downtime. ABB backs it with a 3-year global warranty, 24/7 remote support, and local spare parts in 50+ countries. Customized training and online tutorials ensure teams master configuration and troubleshooting quickly.

Whether you’re upgrading legacy systems, integrating mixed-vendor equipment, or building a new automation network, the **CI627A 3BSE017457R1** delivers the reliable, flexible communication modern industry demands. Contact us for a customized solution tailored to your sector—from automotive manufacturing to offshore oil—and let ABB’s expertise power your operational excellence.