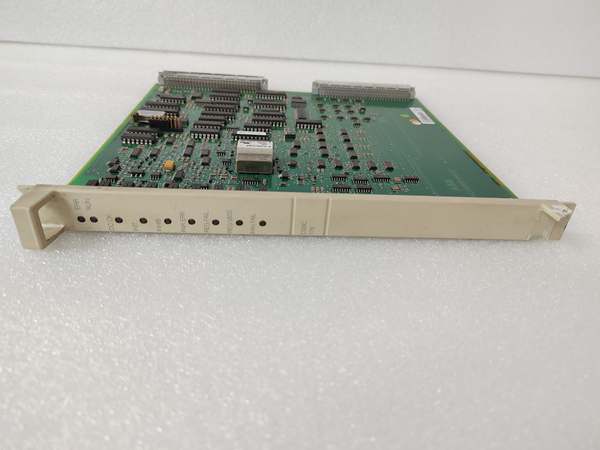

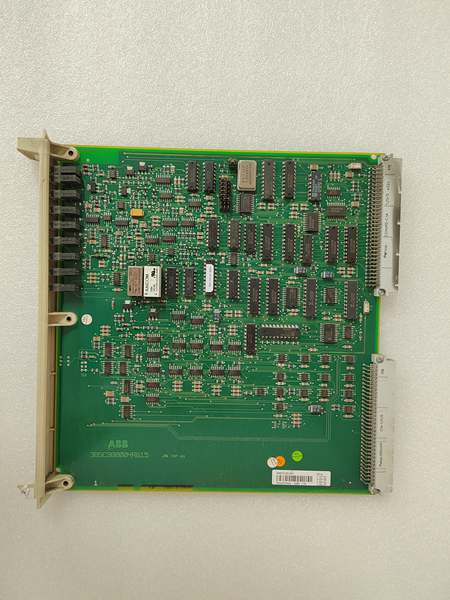

Description

DSBC176 3BSE019216R1

- ••

Model Number: DSBC176 - ••

Order Number: 3BSE019216R1 - ••

Manufacturer: ABB (Triconex) - ••

Product Type: Communication Module - ••

Architecture: Triple Modular Redundant (TMR) - ••

Communication Interface: Serial communication ports - ••

Protocols: Supports industry-standard serial protocols - ••

Data Rate: Programmable baud rates up to 115.2 kbps - ••

Isolation: 1500V RMS port-to-port and port-to-ground isolation - ••

Power Supply: 5VDC from Triconex backplane - ••

Power Consumption: < 5W - ••

Operating Temperature: 0°C to 60°C (32°F to 140°F) - ••

Safety Certification: Suitable for use in SIL 3 applications - ••

Status Indicators: LED indicators for power, activity, and fault status DSBC176 3BSE019216R1