Description

Product Overview

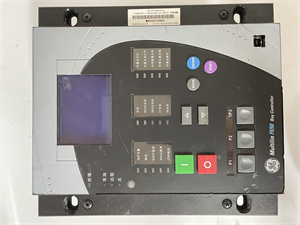

The GE F650 – G – N – A – B – F – 2 – G – 1 – HI – C – E is a high – performance protection and bay controller engineered by General Electric, a globally recognized leader in industrial automation and power systems. It serves as a critical component in ensuring the reliable operation and safety of various industrial setups, especially in power – related applications.

This advanced controller is designed to provide comprehensive protection, control, monitoring, analysis, and power metering functions. Its modular design allows for easy customization and expansion, making it adaptable to different industrial requirements. With its embedded control features, it combines comprehensive feeder protection with programmable logic, enabling users to customize the functions of the feeder protection and control system according to unique needs, which offers great flexibility and cost – efficiency for complex systems. The F650 – G – N – A – B – F – 2 – G – 1 – HI – C – E also comes with an excellent human – machine interface (HMI), which could be a 4 x 20 standard backlit LCD display or an optional 16 x 40 (240×128 pixel) graphical LCD, along with programmable buttons and a rotary switch for menu selection, facilitating user operation and system monitoring.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | F650 – G – N – A – B – F – 2 – G – 1 – HI – C – E |

| Manufacturer | General Electric |

| Product Type | Protection and Bay Controller |

| Input Channels | 16 – 32 digital inputs (configurable) |

| Output Channels | 8 – 16 digital outputs (configurable) |

| Communication Protocols | Modbus RTU, Modbus TCP/IP, DNP 3.0 Level 2, IEC 60870 – 5 – 104, IEC 61850, supports Http, ftp and tftp for internet – related communication |

| Communication Interfaces | RS232, RS485 (up to 115,200 bps), Ethernet (10/100BaseTX, 100BaseFX with ST connectors, optional dual 100BaseFX with ST connectors for redundancy) |

| Protection Functions | Complete set including over – current (instantaneous, delayed, phase – direction, neutral, ground, and sensitive ground), negative – sequence over – current, broken – conductor detection, voltage – restrained phase – over – current, under – voltage/over – voltage for bus and line, neutral – point over – voltage, negative – sequence voltage, under – frequency/over – frequency, breaker failure protection |

| Control Functions | Programmable logic control, auto – reclosing (up to 4 times with independent time settings), 同期检查 (monitoring voltage magnitude, phase – angle, and frequency differences), cold load start with PLC – controlled manual closing |

| Monitoring and Measuring Parameters | Voltage (V), Current (I), Frequency (Hz), Active Power (W), Apparent Power (VA), Power Factor (PF), Demand values (Ia, Ib, Ic, Ig, Isg, I2, MW, MVA), fault location, last 10 records, breaker tripping and failure, VT disconnection, total breaker arcing current |

| Event Storage | 479 events with time – stamping |

| Data Logging | High – resolution oscilloscope and data logger with programmable sampling rate |

| Operating Temperature Range | Industrial – standard range suitable for harsh environments (usually – 25 °C to + 70 °C, but may vary, check manual) |

| Power Supply | Redundant power supply options available, voltage range according to industrial standards (e.g., 24 VDC, 110 VDC, 220 VAC etc., check product details) |

F650-G-N-A-B-F-2-G-1-HI-C-E

Main Features and Advantages

Reliable protection capabilities: The GE F650 – G – N – A – B – F – 2 – G – 1 – HI – C – E offers a wide array of protection functions. For example, in the case of over – current protection, it provides different types such as instantaneous and delayed over – current for phases, neutrals, and grounds. This ensures that in the event of abnormal current conditions, the system can quickly detect and take appropriate action, protecting connected equipment from damage. The breaker failure protection function is also crucial. It can determine if a sent 跳闸 command to a breaker has not been executed within a specified time delay. In such a case, the device will send another 跳闸 signal to all breakers connected to the same bus, effectively isolating the fault and preventing further issues.

Flexible control and customization: With its programmable logic feature, users can tailor the controller to meet specific industrial control requirements. Whether it’s in a complex power distribution network or an industrial production line, the ability to customize control functions allows for optimized system operation. The auto – reclosing function, which can be configured for up to 4 times with independent time settings, is very useful in power systems. It can automatically attempt to reconnect a circuit after a fault, reducing downtime and improving power supply reliability. The 同期检查 function, which monitors voltage magnitude, phase – angle, and frequency differences, ensures that breakers are closed under optimal conditions, preventing damage due to improper synchronization.

Advanced monitoring and measurement: The controller provides detailed monitoring and measurement capabilities. It can measure various electrical parameters such as voltage, current, power, and power factor accurately. The high – resolution oscilloscope and data logger with programmable sampling rates enable in – depth analysis of electrical signals. This is beneficial for diagnosing potential problems in advance. For instance, by analyzing the waveform data, engineers can detect early signs of equipment degradation or abnormal electrical behavior. The ability to store 479 events with time – stamping also helps in post – fault analysis, as it provides a clear record of what occurred leading up to the event.

Good communication and connectivity: Equipped with multiple communication protocols and interfaces, the F650 – G – N – A – B – F – 2 – G – 1 – HI – C – E can easily integrate with existing industrial systems. The Ethernet interfaces, including 10/100BaseTX and 100BaseFX options (with optional redundancy), enable high – speed data transfer, allowing for real – time monitoring and control. Compatibility with protocols like Modbus and IEC standards ensures seamless communication with other devices in the network, whether they are other controllers, sensors, or actuators.

Flexible control and customization: With its programmable logic feature, users can tailor the controller to meet specific industrial control requirements. Whether it’s in a complex power distribution network or an industrial production line, the ability to customize control functions allows for optimized system operation. The auto – reclosing function, which can be configured for up to 4 times with independent time settings, is very useful in power systems. It can automatically attempt to reconnect a circuit after a fault, reducing downtime and improving power supply reliability. The 同期检查 function, which monitors voltage magnitude, phase – angle, and frequency differences, ensures that breakers are closed under optimal conditions, preventing damage due to improper synchronization.

Advanced monitoring and measurement: The controller provides detailed monitoring and measurement capabilities. It can measure various electrical parameters such as voltage, current, power, and power factor accurately. The high – resolution oscilloscope and data logger with programmable sampling rates enable in – depth analysis of electrical signals. This is beneficial for diagnosing potential problems in advance. For instance, by analyzing the waveform data, engineers can detect early signs of equipment degradation or abnormal electrical behavior. The ability to store 479 events with time – stamping also helps in post – fault analysis, as it provides a clear record of what occurred leading up to the event.

Good communication and connectivity: Equipped with multiple communication protocols and interfaces, the F650 – G – N – A – B – F – 2 – G – 1 – HI – C – E can easily integrate with existing industrial systems. The Ethernet interfaces, including 10/100BaseTX and 100BaseFX options (with optional redundancy), enable high – speed data transfer, allowing for real – time monitoring and control. Compatibility with protocols like Modbus and IEC standards ensures seamless communication with other devices in the network, whether they are other controllers, sensors, or actuators.

F650-G-N-A-B-F-2-G-1-HI-C-E

Application Field

The GE F650 – G – N – A – B – F – 2 – G – 1 – HI – C – E has a wide range of applications across diverse industries.

In the power industry, it is extensively used in power distribution systems. It can manage and provide primary protection for distribution lines and bus – ties. For example, in a substation, it monitors the electrical parameters of incoming and outgoing lines, protects against over – current, under – voltage, and other faults, and controls the operation of breakers. It also serves as a backup protection for transformers and transmission lines. In addition, it plays a crucial role in power generation interconnection protection systems, ensuring the safe and stable connection of power generation units to the grid.

In industrial settings such as manufacturing plants, it can be used to protect and control medium – and low – voltage motors. By continuously monitoring the motor’s current, voltage, and other parameters, it can detect abnormal conditions like over – loading or phase – loss and take timely protective actions to prevent motor damage. This helps to maintain the smooth operation of the production line and reduce downtime.

In sectors like oil and gas, petrochemicals, and mining, where reliable power supply is essential, the F650 – G – N – A – B – F – 2 – G – 1 – HI – C – E is used to safeguard the power systems that support various operations. It ensures the stable operation of pumps, compressors, and other critical equipment, protecting them from electrical faults and maintaining the overall safety and efficiency of the production process.

In the power industry, it is extensively used in power distribution systems. It can manage and provide primary protection for distribution lines and bus – ties. For example, in a substation, it monitors the electrical parameters of incoming and outgoing lines, protects against over – current, under – voltage, and other faults, and controls the operation of breakers. It also serves as a backup protection for transformers and transmission lines. In addition, it plays a crucial role in power generation interconnection protection systems, ensuring the safe and stable connection of power generation units to the grid.

In industrial settings such as manufacturing plants, it can be used to protect and control medium – and low – voltage motors. By continuously monitoring the motor’s current, voltage, and other parameters, it can detect abnormal conditions like over – loading or phase – loss and take timely protective actions to prevent motor damage. This helps to maintain the smooth operation of the production line and reduce downtime.

In sectors like oil and gas, petrochemicals, and mining, where reliable power supply is essential, the F650 – G – N – A – B – F – 2 – G – 1 – HI – C – E is used to safeguard the power systems that support various operations. It ensures the stable operation of pumps, compressors, and other critical equipment, protecting them from electrical faults and maintaining the overall safety and efficiency of the production process.

Related Products

- GE F650 – B – F – G – F – 2 – G – 1 – HI – E: It belongs to the same F650 series. While sharing some core features with the F650 – G – N – A – B – F – 2 – G – 1 – HI – C – E, it may have differences in specific configuration options or communication protocol priorities, which could make it more suitable for certain niche applications or legacy systems with specific requirements.

- GE F7126: This is another protection – related module from GE. It might have a different focus in terms of protection functions. For example, it could be more specialized in protecting against specific types of electrical faults like high – impedance faults, while the F650 – G – N – A – B – F – 2 – G – 1 – HI – C – E offers a broader range of general – purpose protection and control features.

- GE DS2020FECNRX010A: It is a module that may work in tandem with the F650 – G – N – A – B – F – 2 – G – 1 – HI – C – E in a larger industrial control system. It could be involved in data processing or signal conditioning tasks, complementing the protection and control functions of the F650 series controller.

- GE DS3800HIOC: This module might be related to input/output control in the context of the overall system. It could interface with external devices to expand the input and output capabilities of the system where the F650 – G – N – A – B – F – 2 – G – 1 – HI – C – E is installed, allowing for connection to more sensors and actuators.

- GE IS420ESWBH3A: It could be a communication – related module. It may enhance the communication capabilities of the system, perhaps enabling communication with specific types of field devices or protocols that the F650 – G – N – A – B – F – 2 – G – 1 – HI – C – E alone might not support natively, thus expanding the system’s connectivity options.

Installation and Maintenance

Pre – installation preparation: Before installing the GE F650 – G – N – A – B – F – 2 – G – 1 – HI – C – E, carefully review the installation manual. Ensure that the installation environment meets the specified requirements, such as appropriate temperature and humidity levels. Check the power supply to confirm it is within the rated voltage range and has proper grounding. Verify that the communication interfaces of other devices in the system are compatible with those of the F650 – G – N – A – B – F – 2 – G – 1 – HI – C – E. Also, make sure to have all the necessary tools for installation, such as screwdrivers and wire strippers.

Maintenance recommendations: Regularly check the status indicators on the GE F650 – G – N – A – B – F – 2 – G – 1 – HI – C – E to ensure normal operation. Periodically clean the device to prevent dust accumulation, which could affect its performance. Monitor the communication connections to ensure stable data transfer. Update the firmware regularly to benefit from the latest features and security patches. If any faults are detected, refer to the troubleshooting section of the manual. In case of complex issues, contact GE’s professional technical support team for assistance.

Maintenance recommendations: Regularly check the status indicators on the GE F650 – G – N – A – B – F – 2 – G – 1 – HI – C – E to ensure normal operation. Periodically clean the device to prevent dust accumulation, which could affect its performance. Monitor the communication connections to ensure stable data transfer. Update the firmware regularly to benefit from the latest features and security patches. If any faults are detected, refer to the troubleshooting section of the manual. In case of complex issues, contact GE’s professional technical support team for assistance.

Product Guarantee

GE stands firmly behind the quality of the F650 – G – N – A – B – F – 2 – G – 1 – HI – C – E protection and bay controller. The product comes with a standard warranty period, typically one year from the date of purchase. During this time, if there are any quality – related issues due to manufacturing defects, GE will provide free repair or replacement services. GE also offers comprehensive technical support. Their team of experts is available to assist customers with any questions regarding installation, configuration, or troubleshooting. This commitment reflects GE’s confidence in the product’s reliability and performance, ensuring that customers can rely on the F650 – G – N – A – B – F – 2 – G – 1 – HI – C – E for their industrial protection and control needs.