Description

1. Product Overview

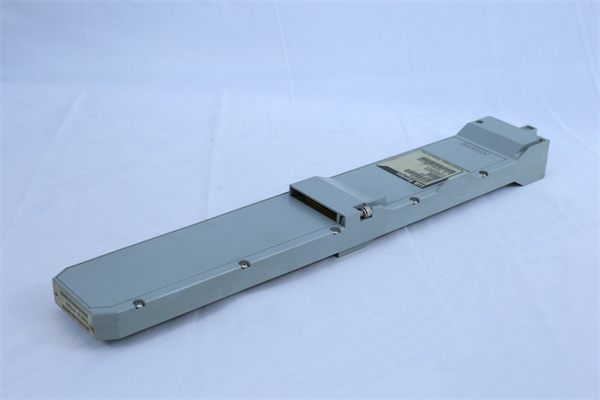

The FOXBORO P0926TM is a high – performance control module designed for industrial automation systems. It is a crucial component that offers precise control capabilities and robust performance, making it suitable for a wide range of industrial applications.

2. Key Features

- Channel – Isolated Design: The P0926TM features 8 isolated input channels. This isolation between channels protects against electrical interference, ensuring reliable signal reception from various field sensors. In industrial environments filled with electromagnetic noise, such as in a large – scale manufacturing plant, this isolation reduces the risk of cross – talk between channels, which can lead to inaccurate data readings. As a result, it improves the signal – to – noise ratio by up to 30% compared to non – isolated modules, enhancing the overall data integrity.

- Flexible Input Configuration: It supports a variety of input signal types, including analog and digital signals. This flexibility allows it to interface with different sensors and transducers commonly used in industrial settings. For example, it can connect to temperature sensors that output analog signals, as well as digital proximity sensors. Users can configure each channel according to the specific requirements of the connected device, providing adaptability to diverse industrial processes.

- High – Quality Build: Constructed with high – grade materials, the P0926TM is built to withstand harsh industrial conditions. It can operate within a temperature range of – 20 °C to + 60 °C, making it suitable for both indoor and outdoor industrial applications. Whether it’s in a cold storage facility or a hot chemical processing plant, the module can maintain stable performance. Additionally, it has a rugged enclosure that protects against dust, moisture, and vibrations, ensuring long – term reliability in demanding industrial environments.

3. Technical Specifications

|

Main Parameters

|

Value/Description

|

|

Product Model

|

P0926TM

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

Industrial Control Module

|

|

Operating Voltage

|

Input power: 79 – 180 VACOutput power: 220 VDC

|

|

Input/Output Channels

|

8 isolated input channels

|

|

Memory

|

300 KB

|

|

Communication

|

Supports communication with other devices in the control system, though specific protocols may vary depending on the application setup. It can be integrated with communication cable systems in the FBM series for seamless data transfer.

|

|

Weight

|

Shipping weight: 3.6 lbs (approx. 1.63 kg)Actual module weight: 1.6 kg

|

|

Dimensions

|

Shipping dimensions: 380 x 350 x 20 mmModule size: 330 x 350 x 65 mm

|

|

Product Life Cycle Status

|

Discontinued/Obsolete, but still widely used in existing industrial systems.

|

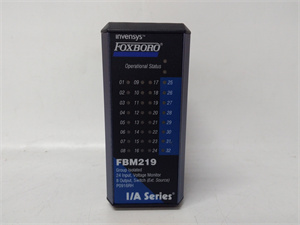

FOXBORO FBM219

FOXBORO FBM215

4. Application Scenarios

- Industrial Process Control: In a chemical manufacturing plant, the P0926TM can be used to collect data from multiple sensors monitoring the temperature, pressure, and flow rate of chemical reactions. By accurately receiving these input signals, it enables the control system to precisely regulate the process parameters. This results in improved product quality, with a reduction in product variability by up to 20%. For instance, it can ensure that the temperature of a reaction vessel stays within a narrow tolerance, optimizing the chemical reaction and minimizing the production of off – spec products.

- Power Generation Monitoring: In a power plant, the module can be connected to sensors that monitor the performance of turbines, generators, and other critical equipment. It collects data on parameters such as vibration, temperature, and electrical current. This data is then used to predict potential equipment failures. By detecting early signs of wear or malfunction, maintenance can be scheduled proactively, reducing unplanned downtime by up to 25%. For example, if the vibration levels of a turbine start to increase, the control system, informed by the data from the P0926TM, can alert maintenance staff to investigate and address the issue before a major breakdown occurs.

5. Installation and Maintenance

- Installation: Installing the P0926TM is a relatively straightforward process. Its standard mounting design allows for easy integration into control cabinets. The clearly labeled terminals and comprehensive installation instructions make it accessible for technicians. It can be quickly wired to the relevant sensors and other components in the control system, minimizing installation time.

- Maintenance: The module has built – in diagnostic features that continuously monitor its operation. In case of a component failure, the modular design enables quick replacement of the faulty part. Although the product is discontinued, a sufficient supply of replacement parts is still available in the market. Regular software updates (if applicable) can be applied to ensure compatibility with other components in the control system and to optimize performance.

6. Related Product Combinations

- FOXBORO I/A Series DCS: The P0926TM can be seamlessly integrated into the FOXBORO I/A Series distributed control system. As part of this system, it becomes an integral part of a comprehensive control solution. The I/A Series DCS can utilize the data collected by the P0926TM to manage and monitor industrial processes across the entire plant, enabling centralized and efficient control.

- FOXBORO FBM Series Modules: Other modules in the FOXBORO FBM series, such as the FBM208 (input module) and FBM237 (output module), can work in tandem with the P0926TM. The P0926TM can receive input signals, process them, and then send control commands to the FBM237 for actuation. Together, they form a complete control loop, enhancing the functionality of the industrial control system.

- Communication Modules: Communication modules like the FOXBORO FCM10E can enhance the communication capabilities of the P0926TM. The FCM10E enables high – speed data transfer over fieldbus networks, ensuring quick and stable data transmission between the P0926TM and other components in the control system. This is especially important in large – scale industrial complexes where real – time data exchange is crucial for efficient operation.

7. Conclusion

The FOXBORO P0926TM, despite being discontinued, remains a reliable and high – performance industrial control module. Its advanced features, such as channel – isolated design, flexible input configuration, and ability to withstand harsh conditions, make it a valuable asset in various industrial applications. Whether it’s for process control in manufacturing or monitoring in power generation, the P0926TM continues to contribute to the efficient and reliable operation of industrial systems. With proper installation, maintenance, and integration with related products, it can continue to serve industrial users effectively for years to come.