Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

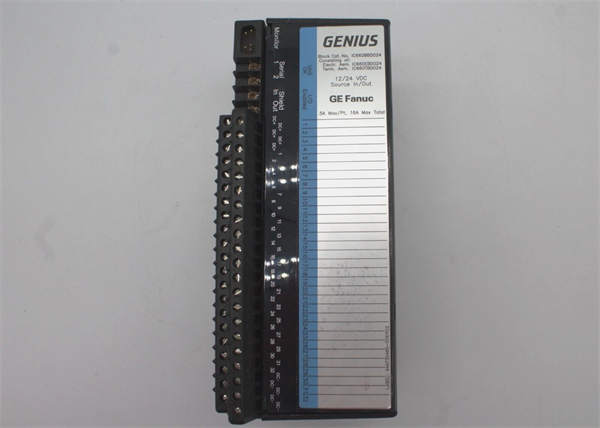

| Product model | GE IC660MLA024 |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | Analog Input Module (Signal Acquisition & Conditioning for Series 90-30 PLC) |

| Input Channel Count | 8 differential analog input channels (fully isolated per channel) |

| Supported Signal Types | Voltage: ±5V DC, ±10V DC, 0–5V DC, 0–10V DC; Current: 4–20mA DC, 0–20mA DC (via external shunt) |

| Measurement Resolution | 12-bit ADC (analog-to-digital converter); ±0.1% full-scale accuracy (25°C) |

| Signal Conditioning | Built-in low-pass filtering (10Hz, 50Hz, 60Hz selectable); Offset/gain calibration (software-adjustable) |

| Input Isolation | Channel-to-channel isolation: 250V AC (1 minute); Channel-to-ground isolation: 500V AC (1 minute) |

| Interface Type | Series 90-30 PLC backplane connector (compatible with IC660BBD020 base unit); 1x 34-pin terminal block (field wiring); 1x calibration port |

| Physical Dimensions (W×H×D) | 102 mm × 165 mm × 38 mm (Series 90-30 modular form factor); Weight: 280 g |

| Installation Method | Slot mounting in Series 90-30 PLC base unit (e.g., IC660BBD020); Requires 1 slot in the base chassis |

| Operating Temperature Range | 0°C to 60°C (ambient); -20°C to 70°C (short-term storage, <72 hours) |

| Relative Humidity Tolerance | 5% to 95% RH (non-condensing); Conformal-coated circuit board (moisture/dust resistance) |

| Power Consumption | 5V DC (from Series 90-30 backplane): 0.8A typical; 1.2A maximum |

| Certifications | CE, UL 508C, IEC 61010-1, CSA C22.2 No. 142; Compliant with industrial safety standards |

| Compatibility | GE Series 90-30 PLC systems (e.g., IC693CPU313, IC693CPU323); Works with GE IC660TSD020 (temperature sensor) and other 4–20mA/voltage sensors |

| Diagnostic Features | Power-on self-test (POST); Channel-level fault detection (over-range, open circuit); LED status indicators per channel |

| LED Indicators | 8x channel LEDs (green = normal, red = over-range/open circuit); 1x module status LED (green = power/communication normal, amber = fault) |

| Data Transfer Rate | Up to 100 samples per second (SPS) total; 12.5 SPS per channel (simultaneous sampling) |

GE IC660MLA024

Product Introduction

The GE IC660MLA024 is a rugged, 8-channel analog input module designed exclusively for GE’s Series 90-30 PLC system—GE’s proven platform for mid-range industrial control. As a core component of the Series 90-30 I/O ecosystem, the GE IC660MLA024 solves a critical challenge in process control: reliably acquiring and conditioning multiple analog signals from field sensors (e.g., pressure transducers, temperature probes like the GE IC660TSD020, and flow meters) before transmitting data to the Series 90-30 PLC.

Unlike generic analog modules that lack system integration, the GE IC660MLA024 is optimized for seamless compatibility with Series 90-30 base units (e.g., IC660BBD020) and CPUs (e.g., IC693CPU313). Its fully isolated channels prevent signal cross-talk and protect the PLC from voltage transients common in industrial environments, ensuring accurate data even near large motors or power lines. In automation systems, the GE IC660MLA024 acts as a “signal translator”: it filters noise from raw analog inputs, calibrates signals to eliminate drift, and converts them into 12-bit digital data the PLC uses to execute control logic—critical for applications like batch processing or continuous manufacturing where precision directly impacts product quality and efficiency.

Core Advantages and Technical Highlights

8-Channel Flexibility with Multi-Signal Support: The GE IC660MLA024’s 8 differential channels support both voltage and current signals, allowing mixed sensor types on the same module—eliminating the need for multiple single-type modules. For example, in a water treatment plant, 4 channels can monitor 4–20mA flow meter signals (from pump outlets), 2 channels track ±10V pressure transducer data (filter tanks), and 2 channels accept 0–5V level sensor inputs (chemical storage tanks). This flexibility reduces module count by 50% compared to fixed-signal modules, saving slot space in the Series 90-30 base unit and lowering overall system costs.

Fully Isolated Channels for Noise Immunity: Each channel of the GE IC660MLA024 features independent isolation (250V AC channel-to-channel, 500V AC channel-to-ground), which blocks ground loops and electrical interference—common in industrial environments with long sensor wiring. For instance, in a manufacturing plant with a 100m cable run from a temperature sensor (GE IC660TSD020) to the PLC, the module’s isolation prevents noise from nearby AC motors from corrupting the 4–20mA signal. This ensures measurement accuracy within ±0.1% full scale, even in high-EMI environments—critical for applications like plastic extrusion, where temperature deviations of 1°C can ruin batches.

Software-Adjustable Calibration and Filtering: The GE IC660MLA024 allows users to calibrate offset and gain for each channel via GE’s VersaPro or CIMPLICITY software—no hardware jumpers required. This simplifies maintenance, as technicians can correct signal drift (e.g., from temperature changes) without removing the module from the base unit. Additionally, selectable low-pass filters (10Hz–60Hz) let users tailor noise reduction to their application: 60Hz filtering for North American power grids, 50Hz for European grids, or 10Hz for slow-changing signals like tank levels. For a food processing plant monitoring slow-moving liquid levels, 10Hz filtering eliminates transient noise from nearby conveyors, ensuring stable readings.

Typical Application Scenarios

In a plastic injection molding facility, the GE IC660MLA024 is installed in a Series 90-30 PLC (IC693CPU323) to monitor 8 critical process parameters: 4 channels for 4–20mA temperature signals (from GE IC660TSD020 sensors in mold cavities), 2 channels for ±5V pressure signals (injection cylinder pressure), and 2 channels for 0–10V flow signals (cooling water flow). The module’s 60Hz filtering eliminates noise from the plant’s electrical grid, while channel isolation prevents cross-talk between high-voltage mold heaters and low-voltage sensors. The PLC uses data from the GE IC660MLA024 to adjust injection speed and cooling flow—ensuring consistent part quality and reducing scrap rates by 15% compared to unfiltered analog inputs.

In a municipal water treatment plant, the GE IC660MLA024 connects to 8 field sensors: 3x 4–20mA pH sensors (chemical mixing tanks), 3x 0–10V level sensors (clarifier tanks), and 2x 4–20mA flow sensors (inlet/outlet pipes). The module’s differential inputs reject common-mode noise from long cable runs (up to 200m), while software calibration corrects pH sensor drift every 6 months. If a clarifier level sensor detects an over-range condition (e.g., tank overflow risk), the GE IC660MLA024 triggers a red channel LED and sends a fault signal to the Series 90-30 PLC. The PLC then activates an alarm and slows the inlet pump—preventing spills and ensuring compliance with environmental regulations.

GE IC660MLA024

Related Model Recommendations

GE IC660BBD020: Series 90-30 base unit (8-slot) that hosts the GE IC660MLA024; provides backplane power and communication with the PLC CPU.

GE IC693CPU313: Series 90-30 PLC CPU that processes digital data from the GE IC660MLA024; executes control logic for industrial processes.

GE IC660TSD020: Temperature sensor (4–20mA output) that pairs with the GE IC660MLA024; ideal for monitoring equipment or process temperatures.

GE IC660MDD024: Analog output module complementary to the GE IC660MLA024; converts PLC digital signals to 4–20mA/voltage outputs for controlling actuators (e.g., valves, pumps).

GE IC660MDL024: Digital input module for Series 90-30 PLC; works with the GE IC660MLA024 to add discrete signal monitoring (e.g., limit switches) to mixed-signal systems.

GE VersaPro: Programming software for Series 90-30 PLC; used to configure the GE IC660MLA024 (calibration, filtering) and develop control logic.

GE IC660PWR020: Power supply module for Series 90-30 base unit; provides stable 5V DC to the GE IC660MLA024 and other I/O modules.

GE IC660MLA016: 4-channel variant of the GE IC660MLA024; ideal for small-scale applications (e.g., standalone pumps) requiring fewer analog inputs.

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the GE IC660MLA024, confirm compatibility with the Series 90-30 base unit (e.g., IC660BBD020) and CPU (e.g., IC693CPU313). Verify the environment meets specs: 0°C–60°C, 5%–95% RH (non-condensing). Required tools include a torque screwdriver (0.4 N·m for base unit screws), wire strippers (22–14 AWG), ESD-safe gloves, and a multimeter. Safety precautions: Power off the base unit (lockout/tagout) to avoid electrical shock; align the module with the base unit slot guides and press firmly until it clicks—do not force the module (risk of backplane pin damage); label field wires (e.g., “PH-TANK-01”) to match the module’s terminal block labels.

Commissioning & Maintenance Suggestions: During commissioning, power on the base unit and verify the GE IC660MLA024’s status LED is green (normal). Use VersaPro software to configure each channel (signal type, filtering) and calibrate offsets/gains using a NIST-traceable signal generator. Test each channel by injecting a known signal (e.g., 12mA for 50% of 4–20mA range) and confirming the PLC receives the correct digital value. For daily maintenance, check the module’s channel LEDs (green = normal, red = fault) and review PLC fault logs for over-range or open-circuit events. Every 6 months, recalibrate channels to correct drift and inspect terminal block connections (retorque to 0.3 N·m). If a channel fault occurs, first check the field sensor and wiring; if the issue persists, replace the GE IC660MLA024 with a GE-approved spare—third-party modules may not meet Series 90-30 compatibility standards.

Service and Guarantee Commitment

The GE IC660MLA024 comes with a 36-month manufacturer’s warranty from GE, covering defects in materials, workmanship, and performance under normal industrial use (per UL 508C and IEC 61010-1 standards). If the GE IC660MLA024 fails within the warranty period, GE provides a “swap-and-repair” service—delivering a tested replacement module within 72 hours for North American customers, minimizing PLC downtime.

GE offers 24/7 technical support for the GE IC660MLA024, including access to Series 90-30 specialists via phone/email and remote troubleshooting (via GE’s Industrial Support Portal). Customers receive free access to VersaPro software updates for 1 year post-purchase, ensuring compatibility with the latest PLC firmware. For legacy system users, GE also offers a “Life Extension Program” for the GE IC660MLA024, which includes extended warranty options and on-site calibration services—reflecting GE’s commitment to supporting long-term operation of Series 90-30 PLC systems.