Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | FE-USI-0002 |

| Manufacturer | Honeywell |

| Product category | Universal safety interface module |

| Input channels | 8 configurable safety inputs (24 VDC) |

| Output channels | 2 safety relay outputs (Form C, 5 A @ 250 VAC) |

| Safety integrity level | SIL 2 (per IEC 61508) |

| Operating voltage | 24 VDC ±15% |

| Power consumption | Max 8 W |

| Response time | ≤2 ms (input to output) |

| Isolation rating | 2.5 kV AC (input to output, input to ground) |

| Operating temperature | -25°C to +70°C (-13°F to +158°F) |

| Dimensions | 100 mm x 80 mm x 60 mm (3.9 in x 3.1 in x 2.4 in) |

| Weight | 0.3 kg (0.66 lbs) |

| Certifications | IEC 61508, UL 508, CE, ATEX |

| Mounting type | DIN rail mounting (35 mm) |

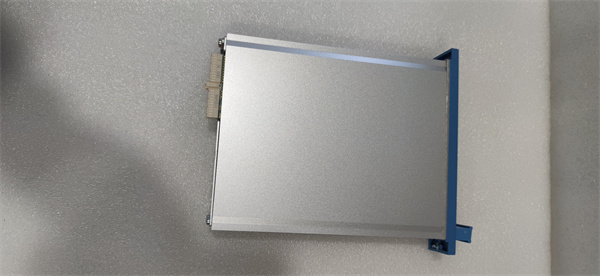

Honeywell FE-USI-0002

Product introduction

The Honeywell FE-USI-0002 is a compact yet robust universal safety interface module designed to bridge safety sensors and control systems in industrial environments. As part of Honeywell’s safety automation portfolio, this module serves as a critical link between field devices (such as emergency stops, light curtains, and interlock switches) and safety controllers or PLCs, ensuring reliable monitoring and control of safety-critical functions.

Honeywell FE-USI-0002 is engineered to simplify safety system design with its configurable 8 input channels and 2 safety relay outputs, making it ideal for small to medium-sized machinery and process applications. Its SIL 2 certification guarantees compliance with global safety standards, providing the integrity needed to prevent accidents in environments where personnel or equipment are at risk. Whether integrated into manufacturing cells, packaging lines, or material handling systems, Honeywell FE-USI-0002 delivers consistent performance, enabling rapid response to safety events while minimizing downtime.

Core advantages and technical highlights

Configurable input flexibility: FE-USI-0002 features 8 individually configurable 24 VDC safety inputs that can accept signals from diverse safety devices—including emergency stop buttons (normally closed), light curtains (PNP/NPN), and guard door interlocks. This versatility eliminates the need for multiple specialized modules, reducing inventory costs and simplifying system architecture. For example, a single FE-USI-0002 can monitor 4 emergency stops, 2 light curtains, and 2 interlock switches in a robotic workcell, streamlining wiring and programming.

Safety-certified performance: With SIL 2 certification per IEC 61508, FE-USI-0002 incorporates built-in diagnostics and fault detection to ensure reliable operation. It continuously monitors for input faults (open circuits, short circuits) and power supply anomalies, triggering immediate output deactivation when faults are detected—preventing unsafe states. The module’s 2.5 kV AC isolation between inputs, outputs, and ground further enhances safety by preventing electrical interference from disrupting critical signals.

Rapid response time: FE-USI-0002 achieves a response time of ≤2 ms from input signal change to output activation, ensuring near-instantaneous reaction to safety events. This speed is crucial for high-speed machinery, where even a small delay could result in injury. For example, in a packaging line with a light curtain breach, the module quickly signals the machine controller to stop operation, limiting exposure to moving parts.

Space-efficient design: Measuring just 100 mm x 80 mm x 60 mm, FE-USI-0002 occupies minimal space in control cabinets—an important feature in compact machinery or retrofitted systems where panel space is limited. Its DIN rail mounting simplifies installation alongside other control components, while its lightweight construction (0.3 kg) reduces structural load on mounting rails.

Typical application scenarios

In automotive manufacturing, FE-USI-0002 is deployed in robotic welding cells to monitor safety devices. Its 8 inputs connect to 4 emergency stop buttons (one at each cell corner), 2 light curtains (protecting access points), and 2 guard door interlocks. When any safety device is triggered, the module’s 2 safety outputs immediately deactivate the robot drive and conveyor system, while sending a signal to the main PLC to halt production. This rapid response prevents contact between operators and moving robotic arms, adhering to ISO 10218 safety standards.

Packaging machinery utilizes FE-USI-0002 to manage safety functions on filling lines. The module monitors 6 interlock switches on access doors (preventing entry during operation) and 2 emergency stops, with outputs controlling the main drive motor and product feed system. Its compact size fits easily in the machine’s control panel, while its fast response time ensures the line stops within milliseconds of a door being opened—preventing product spillage and operator injury.

Material handling systems employ FE-USI-0002 to safeguard conveyor transfer points. The module’s inputs monitor pull-cord emergency stops along the conveyor length and photoelectric sensors detecting personnel in hazardous zones. When activated, its outputs stop the conveyor motor and trigger a local alarm, while communicating the event to the central control system via a PLC. This localized safety control reduces reliance on network latency, ensuring consistent response times across large facilities.

Honeywell FE-USI-0002

Related model recommendations

Honeywell FE-USI-0004: A higher-channel variant of FE-USI-0002 with 16 inputs and 4 outputs, ideal for larger machinery requiring more safety device connections.

Honeywell FW-23-13: Fire alarm control module that can integrate with FE-USI-0002 in systems where safety and fire protection functions need coordination, such as in chemical storage areas.

Honeywell S3000 Safety Controller: Advanced safety PLC that pairs with FE-USI-0002 to manage complex safety logic across multiple modules in large-scale installations.

Honeywell F3SG-4RA: Light curtain system that works seamlessly with FE-USI-0002, providing safeguarding for machine access points with reliable signal transmission to the module.

Honeywell 900S Emergency Stop Button: Safety device commonly connected to FE-USI-0002 inputs, featuring a mushroom head design for easy activation in emergencies.

Honeywell PS24-2A: 24 VDC power supply optimized for FE-USI-0002, ensuring stable power delivery with overload protection critical for safety system reliability.

Installation, commissioning and maintenance instructions

Installation preparation: Mount FE-USI-0002 on a 35 mm DIN rail in a clean, dry control cabinet with ambient temperature between -25°C and +70°C. Ensure at least 10 mm of clearance above and below the module for ventilation. Connect to a 24 VDC power supply (fused at 1A) with dedicated grounding to meet safety isolation requirements. Use 0.5 mm² shielded twisted-pair cables for input connections, routing them separately from power cables to minimize noise. Label each input channel with the connected device (e.g., “E-Stop 1,” “Light Curtain A”) for troubleshooting.

Commissioning and maintenance: Configure FE-USI-0002 using Honeywell’s Safety Configuration Tool, setting input types (normally open/normally closed) and output logic (latching/non-latching) per application requirements. Test each input by simulating device activation (e.g., pressing an emergency stop) and verifying output response using a multimeter or oscilloscope. Perform monthly visual inspections to check for loose connections or terminal corrosion. Annually, test fault detection by intentionally creating open/short circuits on input lines and confirming proper output deactivation. Replace the module only with Honeywell-approved units to maintain SIL 2 certification.

Service and guarantee commitment

Honeywell FE-USI-0002 is backed by a 3-year warranty covering manufacturing defects and ensuring compliance with SIL 2 specifications. Honeywell’s global safety support team provides 24/7 technical assistance, with a 4-hour response time for critical issues, including remote configuration support and troubleshooting guidance.

Customers receive access to detailed installation manuals and certification documentation for FE-USI-0002, supporting regulatory compliance efforts. Extended warranty options up to 5 years include annual functional testing and firmware updates. Honeywell maintains regional stock of FE-USI-0002 modules, enabling next-day delivery for replacement needs. All repairs use genuine components, with post-repair testing to validate safety performance, ensuring customers can trust in the module’s reliability for their safety-critical applications.