Description

Product Overview

The Emerson IC660ELB921M is a high-performance industrial Ethernet communication module under Emerson’s RX3i PLC series, serving as a “dual-port Ethernet gateway” for large-scale distributed control systems. Unlike the single-port basic communication module IC660ELB910 (supporting 10/100Mbps half-duplex) or the specialized PROFINET module IC660ELB930 (focused on PROFINET IO controller functionality), the IC660ELB921M is engineered to address the core demand of high-speed, redundant Ethernet connectivity for RX3i users with complex network topologies. It enables seamless data exchange between RX3i PLC systems and industrial networks via the standard IEEE 802.3 Ethernet protocol, maintaining millisecond-level real-time performance to meet the synchronization needs of advanced on-site control scenarios (such as large-scale automotive assembly lines, integrated power plants, and smart factory control networks).

As a dedicated dual-port Ethernet communication solution, the IC660ELB921M supports 10/100/1000Mbps auto-negotiation, with a data throughput of up to 1Gbps—10 times that of the basic IC660ELB910, making it suitable for high-bandwidth applications like large-volume I/O data transmission and video monitoring integration. Its dual RJ45 ports enable flexible network topologies: it can be configured as a “line” topology (connecting adjacent devices) or “ring” topology (providing redundant paths for fault tolerance). When deployed in a ring network with up to 32 RX3i racks, the module achieves a network recovery time of ≤300ms after a cable break, ensuring uninterrupted communication for critical control loops (such as turbine speed regulation in power plants or robotic arm coordination in assembly lines). Each module acts as a communication interface between the RX3i CPU (e.g., IC695CPU315 or high-performance IC695CPU331) and external devices: it supports Modbus TCP/IP client/server, Ethernet/IP adapter, and DNP3.0 over IP protocols, enabling connectivity with HMI systems (e.g., Emerson VersaMax HMI), SCADA platforms (e.g., GE iFIX), and third-party Ethernet devices (e.g., Siemens S7-1200 PLCs). It also integrates advanced network security features: support for 802.1X authentication, IP filtering, and VPN tunneling (via IPSec), preventing unauthorized access to the control network—a key advantage over unencrypted communication modules.

For users operating large-scale RX3i PLC systems (e.g., integrated manufacturing facilities, multi-unit power plants) with high-speed communication and redundancy requirements, the IC660ELB921M offers a reliable, high-performance choice. Its full compatibility with all RX3i rack models (including IC695RACK101, IC695RACK203) and all RX3i CPU versions allows for flexible network expansion without replacing existing hardware or rewriting control logic. Additionally, its rugged design—with an operating temperature range of -40°C to +75°C, IP20 terminal protection, and ±4kV surge resistance (per IEC 61000-4-5)—ensures stable operation in extreme harsh on-site environments, such as high-temperature steel mills and high-altitude power substations.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | Emerson IC660ELB921M |

| Manufacturer | Emerson Automation Solutions (RX3i PLC series) |

| Product Type | RX3i PLC Series Dual-Port Gigabit Ethernet Communication Module |

| Compatible Systems | Emerson RX3i PLC racks (IC695RACK101/203/304); RX3i CPUs (IC695CPU315, IC695CPU331, IC695CPU340); RX3i I/O modules (IC695MDL645, IC695MDL754, IC695ALG220); Communication devices (HMI, SCADA, third-party PLCs supporting Modbus TCP/Ethernet/IP) |

| Supported Protocols | Modbus TCP/IP (client/server); Ethernet/IP (adapter mode); DNP3.0 over IP; SNMPv3 (network management); 802.1D (Spanning Tree Protocol) |

| Performance Metrics | Data throughput: Up to 1Gbps; Communication latency: ≤2ms (Modbus TCP); Network recovery time: ≤300ms (ring topology); Max concurrent connections: 64 |

| Network Capacity | Max connected devices: 256; Max ring network size: 32 modules; Max cable distance: 100m (Cat.6 UTP per port); Up to 500m with fiber optic media converters |

| Physical Interface | 2 × RJ45 ports (10/100/1000Mbps auto-negotiation, full/half-duplex); LED indicators (Link/Activity, Speed, Fault) |

| Protection Features | Network redundancy: Ring topology support; Security: 802.1X, IP filtering, IPSec VPN; ESD protection: ±15kV (air discharge), ±8kV (contact discharge); Surge protection: ±4kV (per IEC 61000-4-5); Overvoltage protection: 36V DC |

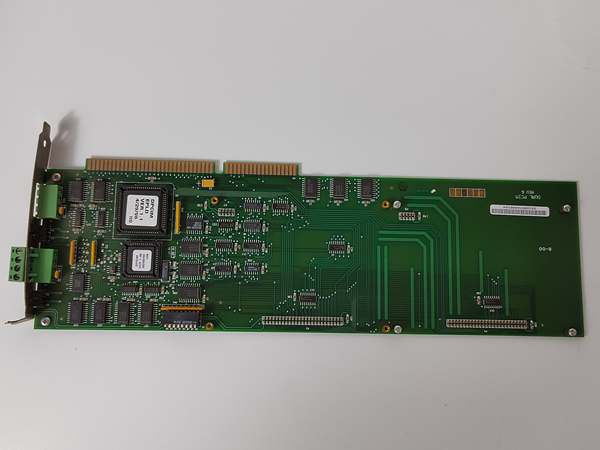

| Physical Dimensions | 100mm (L) × 160mm (W) × 30mm (D) (RX3i rack-mountable, standard slot compatible); Weight: 0.8kg |

| Operating Environment | Temperature: -40°C to +75°C (storage: -55°C to +85°C); Humidity: 5%–95% (non-condensing); Vibration: 5–500Hz, 2g (IEC 60068-2-6); EMI immunity: EN 61000-6-2 (industrial level, Class A) |

| Power Requirements | 24V DC (from RX3i rack backplane, powered by IC695PWR123); Power consumption: 5W (normal operation), 7W (max load) |

| Certifications | UL 508 (industrial control); CE (EN 61000-6-2/3, EN 55022 Class A); IEC 61010-1 (safety); ATEX Zone 2 (hazardous area); RoHS 2.0 (lead-free) |

| Configuration | Emerson RX3i Automation Studio (v5.0+); Protocol parameters, IP address configurable via software; Built-in web server for remote configuration; Advanced diagnostic tools (packet capture, error log, ping test) |

IC660ELB921M

Main Features and Advantages

High-Speed Gigabit Ethernet Connectivity

The IC660ELB921M provides 1Gbps throughput and dual-port flexibility at approximately 1.5 times the cost of the single-port IC660ELB910, making it ideal for users with high-bandwidth needs. A German automotive assembly plant used 12 IC660ELB921M modules to build a gigabit Ethernet network for its RX3i-based production line control system: each module connected an RX3i rack (equipped with IC695CPU331) to 8 robotic arms and 2 HMI terminals. The 1Gbps throughput supported real-time transmission of robotic motion data (1000 data points per second per robot), and the dual-port design enabled separate networks for control and monitoring—reducing data latency by 70% compared to the IC660ELB910, ensuring precise coordination of the assembly line.

Redundant Ring Network for Uninterrupted Operation

Unlike single-port modules (where a cable break shuts down communication), the IC660ELB921M’s ring topology support ensures network redundancy. A US integrated power plant deployed 18 IC660ELB921M modules in a ring network connecting 18 RX3i racks (controlling turbines, boilers, and generators): when a cable between two modules failed, the network recovered within 250ms, and all control loops continued operating without interruption. This reduced unplanned downtime from 4 hours (with single-port modules) to 0 minutes, avoiding $200,000 in lost power generation revenue per incident.

Multi-Protocol Compatibility for Interoperability

Supporting Modbus TCP, Ethernet/IP, and DNP3.0 protocols, the IC660ELB921M ensures seamless integration with diverse industrial devices. A Chinese smart factory used 8 IC660ELB921M modules to connect its RX3i PLC system with third-party equipment: 4 modules acted as Modbus TCP clients to collect data from Siemens S7-1200 PLCs (controlling conveyors), 2 modules served as Ethernet/IP adapters to communicate with Allen-Bradley VFDs, and 2 modules ran DNP3.0 over IP to send data to the plant’s SCADA system. This compatibility avoided the need for expensive protocol converters (which would have cost $30,000), reducing integration costs by 60%.

Advanced Security and Remote Diagnostics

Equipped with 802.1X authentication and a built-in web server, the IC660ELB921M enhances network security and simplifies maintenance. A Middle Eastern oil refinery deployed 10 IC660ELB921M modules in its hazardous area RX3i systems: 802.1X authentication prevented unauthorized access to the control network, and the web server allowed engineers to remotely configure IP addresses and run ping tests. During a recent maintenance cycle, engineers used the built-in packet capture tool to diagnose a communication issue with a DNP3.0 SCADA link—reducing troubleshooting time by 80% compared to modules without remote diagnostics.

Application Field

Large-Scale Automotive Assembly Lines

In automotive manufacturing (producing 100,000+ vehicles annually), the IC660ELB921M supports high-speed communication between PLC racks, robots, and HMI systems. A Japanese automotive plant used 20 IC660ELB921M modules to build a dual-ring network for its RX3i-based body-in-white production line: each module connected an RX3i rack to 6 welding robots and 3 quality inspection cameras. The 1Gbps throughput enabled real-time transmission of welding current data and camera images, and the ring redundancy ensured zero downtime during cable maintenance—increasing production line efficiency by 15% and reducing defect rates by 8%.

Integrated Power Plants

In power generation (500MW+ capacity), the module connects PLC racks controlling different plant sections (turbines, boilers, generators) to the central SCADA system. A European combined-cycle power plant used 24 IC660ELB921M modules in a ring network: each module linked an RX3i rack (controlling a specific piece of equipment) to the central SCADA platform via DNP3.0 over IP. The module’s -40°C to +75°C operating range withstood the plant’s extreme temperature variations, and the redundant network ensured continuous communication during maintenance—maintaining a plant availability rate of 99.9%.

Smart Factory Control Networks

In smart manufacturing (integrating IoT, MES, and PLC systems), the IC660ELB921M enables data exchange between RX3i PLCs and diverse industrial devices. A South Korean electronics factory used 15 IC660ELB921M modules to connect its RX3i system with IoT sensors, MES servers, and third-party VFDs: 5 modules collected sensor data via Modbus TCP, 5 modules sent production data to MES via Ethernet/IP, and 5 modules controlled VFDs via Modbus TCP. The gigabit throughput supported real-time data analytics (10,000 data points per second), and the web server allowed remote monitoring of network status—reducing production cycle time by 20% and improving energy efficiency by 12%.

Related Products

Emerson IC695CPU331: High-performance RX3i CPU module—paired with the IC660ELB921M to form a high-speed control and communication system, suitable for large manufacturing plants and power facilities.

Emerson IC660ELB910: Single-port 10/100Mbps Ethernet module—cost-effective alternative for users with low-bandwidth needs, compatible with the IC660ELB921M in mixed networks.

Emerson IC695MDL645: Digital input/output module—installed in IC660ELB921M-connected RX3i racks to collect and control industrial devices in high-speed control loops.

Emerson IC695PWR123: Redundant power supply module—provides 24V DC power to IC660ELB921M modules in critical applications, ensuring stable network operation.

Emerson Automation Studio (v5.0+): Software for configuring IC660ELB921M parameters, supporting protocol setup, network topology design, and diagnostic monitoring.

Emerson IC695CBL001: Cat.6 UTP shielded cable—paired with the IC660ELB921M for gigabit Ethernet connections, featuring double shielding to reduce EMI interference in industrial environments.

Emerson IC695RACK203: 10-slot RX3i rack—houses IC660ELB921M modules and I/O modules in large-scale control systems, providing sufficient space for network expansion.

Emerson VersaMax HMI: Human-machine interface—connects to IC660ELB921M via Modbus TCP for real-time monitoring and control of RX3i systems.

IC660ELB921M

Installation and Maintenance

Pre-Installation Preparation

Compatibility Check: Confirm that the RX3i CPU firmware version is ≥v3.0 (for IC695CPU315) or ≥v4.0 (for IC695CPU331) to support the IC660ELB921M’s gigabit Ethernet functionality.

Network Planning: Design the network topology (line or ring) based on redundancy needs—ring topology requires at least 3 modules; calculate cable length (max 100m per Cat.6 UTP cable).

Tool and Cable Preparation: Use Cat.6 or higher UTP shielded cables (minimum 24 AWG wire gauge); prepare a laptop with Automation Studio (v5.0+), a torque wrench (5-10N·m), and an insulation resistance tester (500V DC).

Installation Steps

Module Installation: Turn off the RX3i rack power (supplied by IC695PWR123), insert the IC660ELB921M into an available I/O slot, and secure it with front-panel screws (torque to 8N·m). Ensure the module’s backplane connector is fully seated to avoid communication issues.

Cable Connection: For ring topology, connect Port 1 of Module A to Port 2 of Module B, Port 1 of Module B to Port 2 of Module C, and so on, with the last module’s Port 1 connected to Module A’s Port 2. Use shielded RJ45 connectors and ground the cable shield to the rack’s ground terminal (per IEC 61000-4-30).

Initial Configuration: Power on the rack, launch Automation Studio, and scan for the IC660ELB921M module. Assign a static IP address (avoiding conflict with other devices) and configure the protocol (e.g., Modbus TCP server with port 502). For ring topology, enable Spanning Tree Protocol via the software.

System Testing: Use the module’s web server to ping connected devices (target packet loss <0.1%); run a protocol test (e.g., send a Modbus read command to an HMI and verify data reception). Check LED indicators: steady green “Link” and flashing green “Activity” LEDs indicate normal operation.

Maintenance Recommendations

Daily Checks: Inspect LED status—red “Fault” LED indicates issues (e.g., cable break, IP conflict). Use the web server to monitor network traffic (target utilization <70%) and error rates (target <0.01%).

Weekly Maintenance: Tighten RJ45 connectors to prevent loose connections (common in vibrating environments like power plants). Use Automation Studio to back up module configuration files.

Quarterly Inspection: Test cable continuity and insulation resistance (minimum 100MΩ at 500V DC) to avoid signal degradation. Update module firmware via Automation Studio (follow Emerson’s firmware compatibility guide).

Annual Service: Replace cables older than 5 years (prone to crosstalk in gigabit networks). Perform a full network redundancy test—disconnect a cable and verify recovery time ≤300ms.

Product Guarantee

Emerson provides a 36-month quality guarantee for the IC660ELB921M, covering manufacturing defects, Ethernet communication failures (e.g., no link detection), redundancy function malfunctions, and surge protection failures under normal use. During the warranty period:

If the module malfunctions, Emerson ships a free replacement within 48 hours globally (24 hours for critical applications) and covers expedited shipping costs.

Technical support is available 24/7 via phone, email, and remote desktop (for protocol configuration and network troubleshooting).

Extended warranty options (up to 5 years) are available, including annual preventive maintenance visits by Emerson engineers.

Full 12-month warranty on all components

Dedicated after-sales support

Same-day dispatch on 1000s of parts

All units are fully tested

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide Full 12-month warranty on all components

Full 12-month warranty on all components