Description

GE IS200BAIAH1BEE Product Description

Product Overview

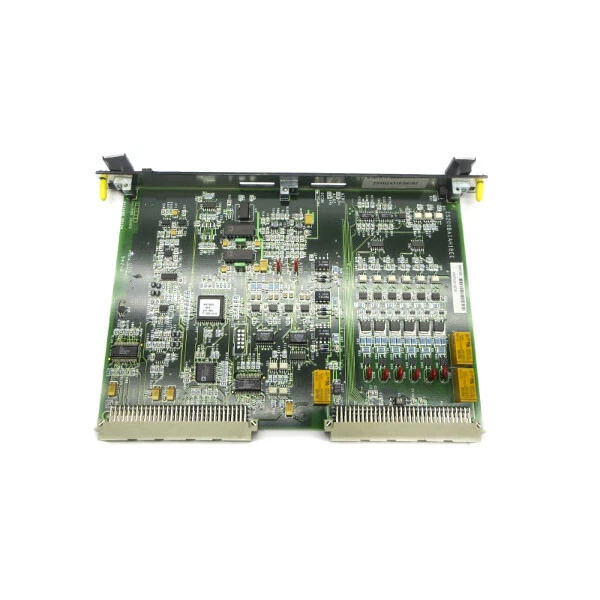

The GE IS200BAIAH1BEE is a bridge application interface card designed for GE’s Speedtronic™ Mark VI/VIe distributed control systems (DCS), serving as a critical communication gateway between the IS200DSPXH1CAA digital signal processor (DSP) module and external devices such as drive system keypads, PCs, or auxiliary control systems. As part of GE’s Innovation Series—a subseries of the Mark VI platform—it enables real-time data exchange and command execution in gas, steam, and wind turbine control architectures .

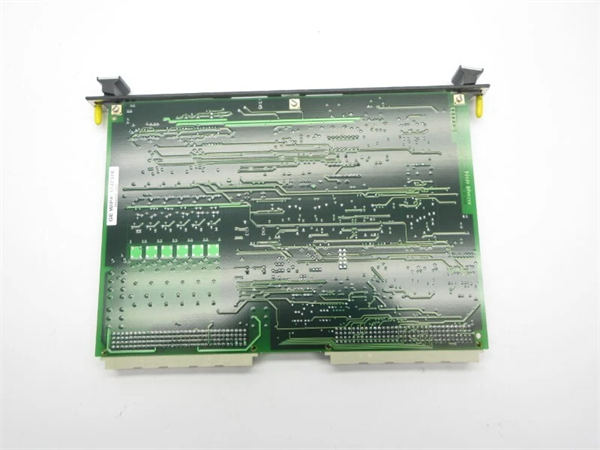

Engineered for rugged industrial environments, GE IS200BAIAH1BEE features a factory-preprogrammed EEPROM that ensures plug-and-play compatibility with Mark VI systems. Its RS-232C I/O interface facilitates bidirectional communication with external HMI devices, while its dual backplane connectors (P1 and P2) enable seamless integration into the Mark VI VME rack . Unlike analog I/O modules (e.g., GE IS200DTCIH1ABB), GE IS200BAIAH1BEE focuses on protocol conversion and signal routing rather than direct sensor/actuator interfacing. This makes it ideal for retrofitting legacy systems or extending control capabilities without modifying core hardware .

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | GE IS200BAIAH1BEE |

| Manufacturer | General Electric (GE) |

| Product Type | Bridge Application Interface Card (Mark VI Innovation Series) |

| Compatible Systems | GE Speedtronic Mark VI/VIe DCS; IS200 series modules (e.g., DSPX, BICLH) |

| Communication Interface | RS-232C (for external devices); VME backplane (for internal module connectivity) |

| Power Input | 24V DC (via backplane; from GE IS200TPSAG1A redundant power supply) |

| Mounting Type | 19-inch rack-mount (1U height); must be installed in Slot 1 of the VME rack |

| Physical Dimensions | 482.6mm (W) × 44.5mm (H) × 152.4mm (D) |

| Weight | 0.65kg (1.43lb) |

| Diagnostic Features | LED indicator (IMOK: indicates module health); fault logging via Mark VI HMI |

| EEPROM | Factory-preloaded firmware (non-reprogrammable; replacement required if faulty) |

| Backplane Connectors | 2 × 50-pin high-density connectors (P1 and P2) |

IS200BAIAH1BEE

Main Features and Advantages

1. Seamless DSP Integration

GE IS200BAIAH1BEE acts as a dedicated interface for the IS200DSPXH1CAA, translating DSP-generated control signals into RS-232C commands for external devices. This ensures precise coordination between high-speed control algorithms and legacy HMI systems—a critical capability for retrofitting older turbines with modern automation .

2. Plug-and-Play Simplicity

With a preconfigured EEPROM and standardized VME interface, GE IS200BAIAH1BEE eliminates the need for custom firmware programming. A European power plant reduced commissioning time by 20% during a Mark VI upgrade by leveraging this plug-and-play design .

3. Rugged Industrial Design

Conformal coating and galvanic isolation (2500Vrms) protect GE IS200BAIAH1BEE from EMI/RFI interference and voltage transients, ensuring reliable operation in harsh environments like turbine halls or offshore platforms .

4. Slot-Specific Installation

A warning label on the module’s faceplate mandates installation in Slot 1 of the VME rack, preventing misconfiguration and hardware damage. This strict slot assignment optimizes backplane communication topology .

Application Field

GE IS200BAIAH1BEE is pivotal in industries where legacy systems require integration with modern control architectures, with key applications in:

1. Power Generation

Gas/Steam Turbines: Bridges the IS200DSPXH1CAA to remote HMIs or third-party monitoring systems, enabling real-time parameter adjustment and fault diagnostics. A 500MW coal-fired plant in India used GE IS200BAIAH1BEE to integrate a new SCADA system with its existing Mark VI controller, reducing downtime by 30% .

Wind Turbines: Facilitates communication between the Mark VI controller and pitch/yaw control systems, ensuring grid-compliant power output. A U.S. wind farm achieved 99.8% uptime by leveraging GE IS200BAIAH1BEE for remote blade adjustment .

2. Oil & Gas

Offshore Platforms: Connects the Mark VI system to subsea sensors and actuators, supporting real-time monitoring of compressor status and wellhead pressure. A North Sea platform avoided a $150,000 shutdown by using GE IS200BAIAH1BEE to route emergency shutdown signals .

3. Industrial Automation

Process Control: Integrates Mark VI with PLCs or DCS systems in petrochemical plants, enabling coordinated control of turbines, pumps, and reactors. A European refinery reduced control loop latency by 25% after deploying GE IS200BAIAH1BEE .

Related Products

| Product Model | Role in System |

| GE IS200DSPXH1CAA | Digital signal processor that sends/receives data via GE IS200BAIAH1BEE |

| GE IS200BICLH1BBA | Backplane communication module that works alongside GE IS200BAIAH1BEE |

| GE IS200TPSAG1A | Redundant power supply for GE IS200BAIAH1BEE |

| GE IC660HHM501 | Handheld monitor used to test RS-232 communication integrity of GE IS200BAIAH1BEE |

| GE IS200BAIAH1BBD | Upgraded variant with Ethernet connectivity (for smart grid applications) |

IS200BAIAH1BEE

Installation and Maintenance

Pre-Installation Preparation

Compatibility Check: Verify Mark VI system software version (≥6.5 for Mark VI, ≥7.0 for Mark VIe) and slot availability in the VME rack.

ESD Protection: Use anti-static wristbands and tools to prevent damage to the EEPROM and backplane connectors.

Labeling: Mark RS-232 cables to avoid misconnection between GE IS200BAIAH1BEE and external devices .

Maintenance Recommendations

Monthly Inspections:

Check IMOK LED for module health.

Tighten backplane connectors and inspect for corrosion.

Quarterly Testing:

Use GE IC660HHM501 to verify RS-232 signal integrity.

Simulate a module fault to ensure the Mark VI HMI logs errors correctly.

Firmware Management:

Never reprogram the EEPROM; replace the module if firmware corruption is suspected .

Product Guarantee

GE provides a 1-year standard warranty for GE IS200BAIAH1BEE, covering defects in materials and workmanship. Warranty services include:

Free replacement of faulty modules.

24/7 technical support for RS-232 configuration and backplane troubleshooting.

Priority access to GE’s global repair network, which restores modules to factory specifications using OEM parts .

For mission-critical applications (e.g., nuclear auxiliary systems), extended warranties (up to 3 years) and on-site commissioning services are available. These ensure GE IS200BAIAH1BEE meets the highest reliability standards in safety-critical environments .

Full 12-month warranty on all components

Dedicated after-sales support

Same-day dispatch on 1000s of parts

All units are fully tested

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide Full 12-month warranty on all components

Full 12-month warranty on all components