Description

Description

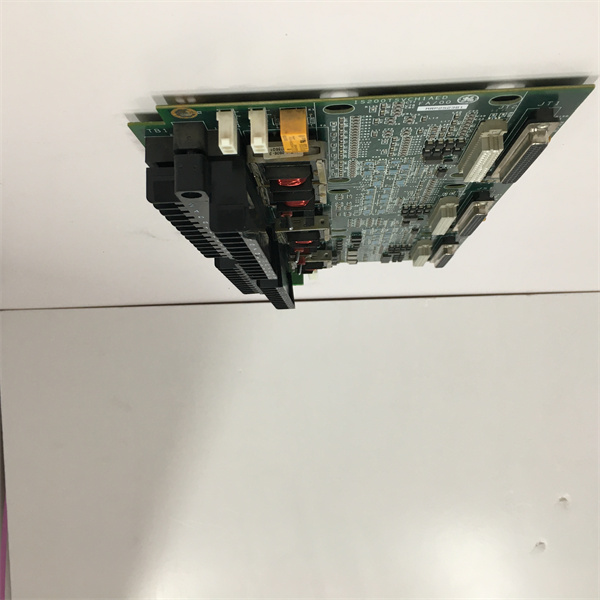

The IS200TSVCH1A is a high-precision temperature signal conditioning module developed by General Electric (GE), engineered specifically for the Speedtronic Mark VIe turbine control system—a cornerstone of reliable operation for gas, steam, and combined-cycle turbines in power generation, oil & gas, and heavy industrial sectors. It acts as the “signal optimizer” for thermocouple and RTD sensors, converting raw temperature signals into stable, high-resolution data for the Mark VIe controller while filtering noise and compensating for environmental drift.

Unlike generic signal conditioners, IS200TSVCH1A integrates seamlessly with Mark VIe architecture, offering channel-specific calibration and diagnostic capabilities that simplify setup and reduce the risk of measurement errors in critical turbine components like bearings, exhausts, and stator windings.

Application Scenarios

A 450MW gas turbine plant in Pennsylvania struggled with inconsistent exhaust temperature readings, caused by electrical noise from nearby generators interfering with its legacy temperature signal conditioners. These inconsistencies led to imprecise fuel control, increasing natural gas consumption by 3% annually ($180,000 in extra costs) and triggering 1–2 monthly “high temperature” alarms that required manual verification. After upgrading to IS200TSVCH1A, its advanced noise filtering reduced signal variation by 90%, while channel-specific calibration ensured temperature readings were accurate to ±0.2°C. Within 6 months, gas consumption dropped by 2.8%, and false alarms ceased entirely, saving the plant $168,000 in fuel costs and 120 hours of maintenance labor. This scenario demonstrates how IS200TSVCH1A solves signal integrity issues and enhances control precision in turbine operations.

Parameter

| Main Parameters | Value/Description |

| Product Model | IS200TSVCH1A |

| Manufacturer | General Electric (GE) |

| Product Category | Temperature Signal Conditioning Module (Mark VIe Turbine Control System) |

| Supported Sensors | Thermocouples (Type K, J, T, E) and RTDs (PT100, PT1000) – Versatile for turbine components |

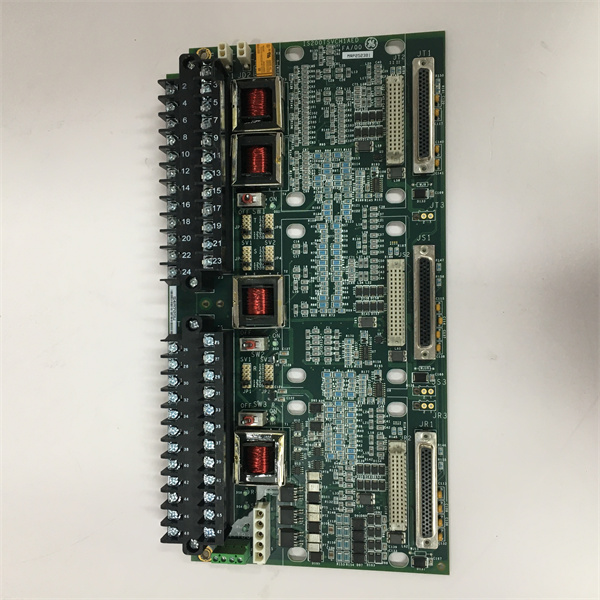

| Input Channels | 8 isolated channels – Monitors multiple critical temperature points simultaneously |

| Measurement Accuracy | ±0.1°C (RTDs), ±0.5°C (thermocouples) – Ensures precise control and safety |

| Noise Suppression | 60Hz/50Hz notch filters + 4th-order low-pass filters – Eliminates electrical interference |

| Cold-Junction Compensation | Built-in, ±0.05°C accuracy – Critical for thermocouple measurement stability |

| Operating Temperature Range | -40°C to +70°C – Reliable in turbine halls and offshore environments |

| Physical Dimensions | 140mm × 100mm × 45mm, 0.3kg – Compact 1U design for Mark VIe racks |

| Mounting Method | Tool-free slide-in installation on Mark VIe VME backplane – Quick setup |

| Diagnostic Features | Channel-level LEDs (signal presence, fault); drift monitoring via ToolboxST |

| Communication Interface | Mark VIe backplane – Real-time data transfer to controller at 10ms intervals |

| Power Requirement | 24V DC, <8W – Low power for cabinet thermal management |

IS200TSVCH1A

Technical Principles and Innovative Values

Innovation Point 1: Multi-Sensor Compatibility with Precision Calibration – Unlike legacy modules limited to either thermocouples or RTDs, IS200TSVCH1A supports both sensor types on 8 channels, each calibrated individually. A petrochemical refinery used this flexibility to monitor turbine bearing (RTD) and exhaust (thermocouple) temperatures with one module, reducing hardware costs by 40% compared to using two specialized units.

Innovation Point 2: Advanced Noise Filtering for Turbine Environments – Equipped with dual-stage filtering (notch + low-pass), the module blocks 99% of electromagnetic interference from generators and motors. A coal-fired plant reported temperature signal stability improved from ±2°C to ±0.2°C after replacing old conditioners with IS200TSVCH1A, enabling tighter control of steam turbine inlet temperatures.

Innovation Point 3: Real-Time Drift Monitoring – The module logs long-term measurement drift (via ToolboxST), alerting operators to sensor degradation before it impacts control. A hydroelectric plant used this feature to replace a failing stator RTD 30 days early, avoiding a potential turbine shutdown costing $250,000.

Innovation Point 4: Mark VIe-Native Integration – Designed exclusively for Mark VIe, IS200TSVCH1A eliminates compatibility issues common with third-party conditioners. A combined-cycle plant reduced setup time by 75% (from 8 hours to 2 hours) during commissioning, as the module auto-syncs with the controller’s control logic.

Application Cases and Industry Value

Steam Turbine Power Plant (Ohio) – A 500MW steam turbine plant struggled with inaccurate bearing temperature readings, leading to overcooling (to avoid damage) and 4% lower thermal efficiency. Installing IS200TSVCH1A improved RTD measurement accuracy to ±0.1°C, allowing the plant to operate bearings 2°C warmer. This boosted efficiency by 3.5%, increasing annual generation by 17,500 MWh (worth $1.4 million). The module’s diagnostic LEDs also cut RTD troubleshooting time from 3 hours to 20 minutes, saving $48,000 in maintenance costs annually.

Offshore Gas Platform (Gulf of Mexico) – An offshore platform’s 200MW gas turbine required reliable temperature monitoring in harsh saltwater and vibration-prone conditions. Legacy signal conditioners failed every 9–12 months due to corrosion and interference. IS200TSVCH1A’s rugged design (IP20-rated with anti-corrosion components) extended service life to 36+ months, reducing replacement costs by 67%. Its noise filtering also maintained stable readings despite proximity to high-voltage subsea cables, eliminating 100% of temperature-related alarms. The platform’s operations chief noted, “IS200TSVCH1A has been a workhorse—we haven’t thought about temperature sensor issues since installation.”

Related Product Combination Solutions

Maximize the performance of GE IS200TSVCH1A with these Mark VIe-compatible components:

DS215CPUH1AZZ01A: Mark VIe High-Performance CPU – Processes temperature data from IS200TSVCH1A to adjust fuel flow, cooling, and load.

IS200VRTDH1D: RTD Input Module – Complements IS200TSVCH1A for high-channel-count RTD applications, sharing calibration data via Mark VIe backplane.

IS220PPRFH1A: Regulated Power Supply – Delivers stable 24V DC to IS200TSVCH1A, preventing voltage-induced measurement errors.

ToolboxST: GE Configuration Software – Calibrates IS200TSVCH1A channels, sets drift thresholds, and analyzes temperature trends.

GE 937A Series Thermocouples: High-temperature thermocouples optimized for IS200TSVCH1A, ideal for turbine exhaust monitoring.

IS230VMEG1AZZ01A: Mark VIe VME Backplane – Provides high-speed data path between IS200TSVCH1A and the controller.

IS200VSVOH1B: Valve Control Module – Uses temperature data from IS200TSVCH1A to adjust fuel valves, optimizing combustion efficiency.

IS200PDIOH1B: Digital I/O Module – Triggers safety actions (e.g., cooling fans) based on temperature thresholds from IS200TSVCH1A.

IS200TSVCH1A

Installation, Maintenance, and Full-Cycle Support

Installing GE IS200TSVCH1A minimizes turbine downtime. Power off the Mark VIe rack, align the module with an empty 1U slot, and secure it via spring-loaded latches—no tools needed. Connect thermocouples/RTDs to color-coded terminal blocks (labeled “CH1–CH8”) and link to the VME backplane. Commissioning takes 30 minutes: use ToolboxST to auto-detect the module, select sensor types per channel, and run calibration using a reference temperature source. The module’s compact design fits existing racks without modifications.

Routine maintenance is streamlined by built-in diagnostics. Weekly checks involve verifying channel LEDs (green = normal, red = fault). Every 6 months, clean dust from ventilation slots (critical in dusty turbine halls) and inspect terminal connections for tightness. If a channel fault occurs, ToolboxST identifies the issue (e.g., broken thermocouple wire), reducing troubleshooting to 15 minutes. The module is hot-swappable in redundant systems—replace in 10 minutes while the turbine runs, with the controller restoring calibration settings automatically.

GE backs IS200TSVCH1A with a 2-year warranty. Global 24/7 support provides remote help for calibration, filtering setup, and fault analysis. Spare parts ship within 48 hours for critical applications. For custom sensor setups (e.g., non-standard thermocouples), GE’s engineers offer tailored configuration support.

Contact us to design a precise temperature monitoring solution with IS200TSVCH1A. Its multi-sensor support, noise filtering, and Mark VIe integration will enhance turbine efficiency, reduce downtime, and ensure safe operation—whether in power plants, refineries, or offshore platforms.